A kind of composite brazing material and brazing process

A technology of brazing material and brazing process, applied in the direction of welding/cutting media/materials, welding equipment, manufacturing tools, etc., can solve the problems of low welding quality, improve the yield of welded parts, reduce the brazing temperature, and improve The effect of weldment quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

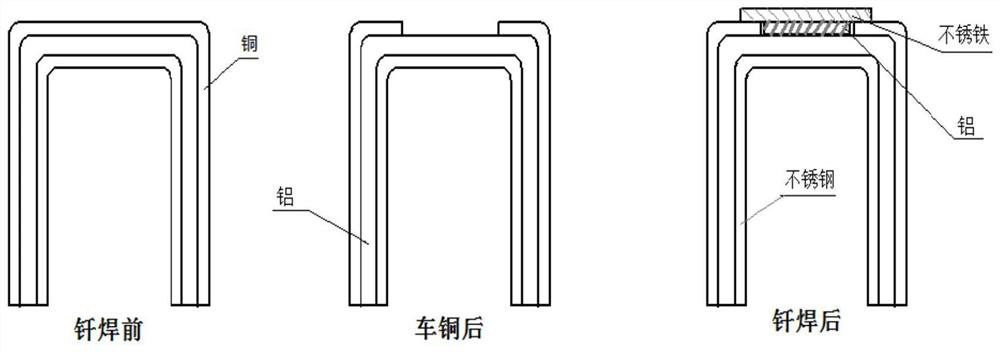

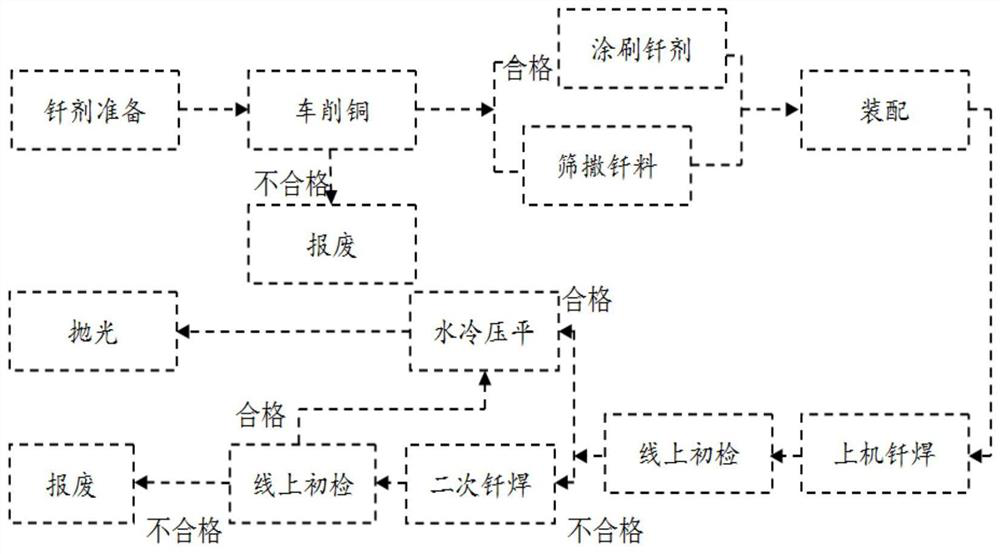

[0043] This embodiment provides a composite brazing material and a brazing process, which specifically includes the following steps:

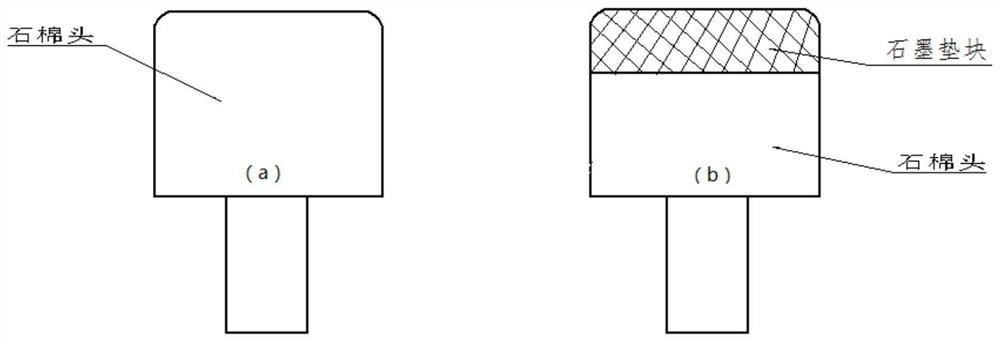

[0044] S1: Improve the lower die head of the existing tooling of the brazing machine. Change the material of the tooling lower die head of the brazing machine from asbestos to asbestos die head and add a graphite pad with better thermal conductivity and a thickness of 10mm to form a composite structure die head (see image 3 );

[0045] S2: Prepare a flux slurry made of a compound flux made of 60% cesium fluoroaluminate and 40% potassium fluoroaluminate and water at a weight ratio of 1.0:2.0;

[0046] S3: Apply the flux slurry to both sides of the aluminum plate brazed with the copper-aluminum-stainless steel composite material with a brush;

[0047] S4: Evenly sieve aluminum-silicon (Al88Si12) brazing material less than 60 mesh to more than 200 mesh on both sides of the aluminum plate coated with flux slurry, and the amount of sifting is 5kg...

Embodiment 2

[0053] This embodiment provides a composite brazing material and a brazing process, which specifically includes the following steps:

[0054] S1: Improve the lower die head of the existing tooling of the brazing machine. Change the material of the tooling lower die head of the brazing machine from asbestos to asbestos die head and add a graphite pad with better thermal conductivity and a thickness of 15mm to form a composite structure die head (see image 3 );

[0055] S2: Prepare a flux slurry made of a compound flux made of 80% cesium fluoroaluminate and 20% potassium fluoroaluminate and water at a weight ratio of 1.0:2.5;

[0056] S3: Apply the flux slurry to both sides of the aluminum plate brazed with the copper-aluminum-stainless steel composite material with a brush;

[0057] S4: Evenly sieve aluminum-silicon (Al88Si12) brazing material less than 70 mesh to more than 200 mesh on both sides of the aluminum plate coated with flux slurry, and the amount of sifting is 5kg...

Embodiment 3

[0063] This embodiment provides a composite brazing material and a brazing process, which specifically includes the following steps:

[0064] S1: Improve the lower die head of the existing tooling of the brazing machine. Change the material of the lower die head of the tooling of the brazing machine from asbestos to asbestos die head and add a graphite pad with better thermal conductivity and a thickness of 20mm to form a composite structure die head (see image 3 );

[0065] S2: The flux slurry is prepared by adjusting the compound flux made of 90% cesium fluoroaluminate and 10% potassium fluoroaluminate and water in a weight ratio of 1.0:3.0;

[0066] S3: Apply the flux slurry to both sides of the aluminum plate brazed with the copper-aluminum-stainless steel composite material with a brush;

[0067] S4: Evenly sieve aluminum-silicon (Al88Si12) brazing filler metal of less than 80 mesh to more than 200 mesh on both sides of the aluminum plate coated with flux slurry, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com