Bimetal metallurgical composite pipe and manufacturing method thereof

A composite pipe and bimetallic technology, which is applied in the field of bimetallic metallurgical composite pipe and its preparation, can solve the problems of bimetallic composite pipe interface strength, oil pipe end treatment, etc., and achieve the effect of compact structure, straight joint interface and uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

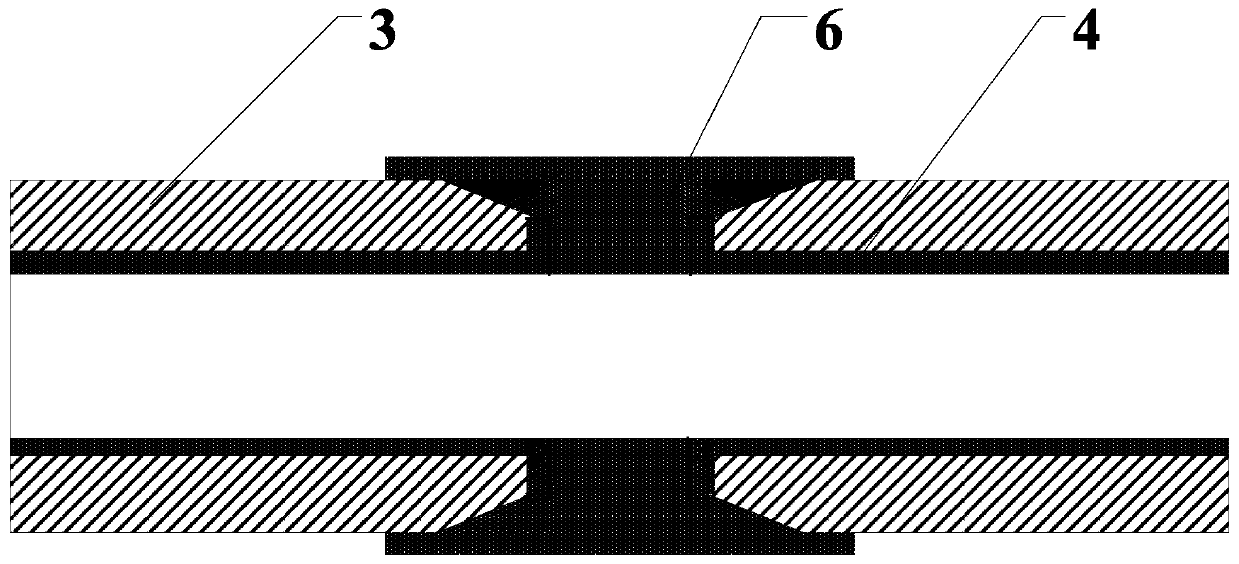

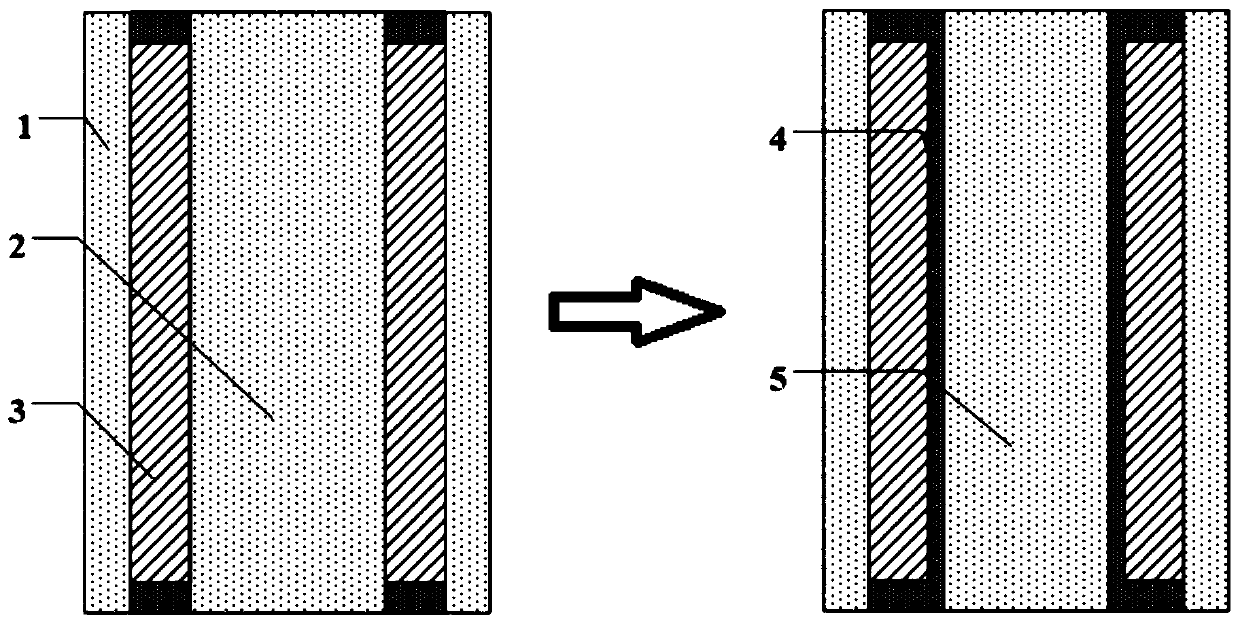

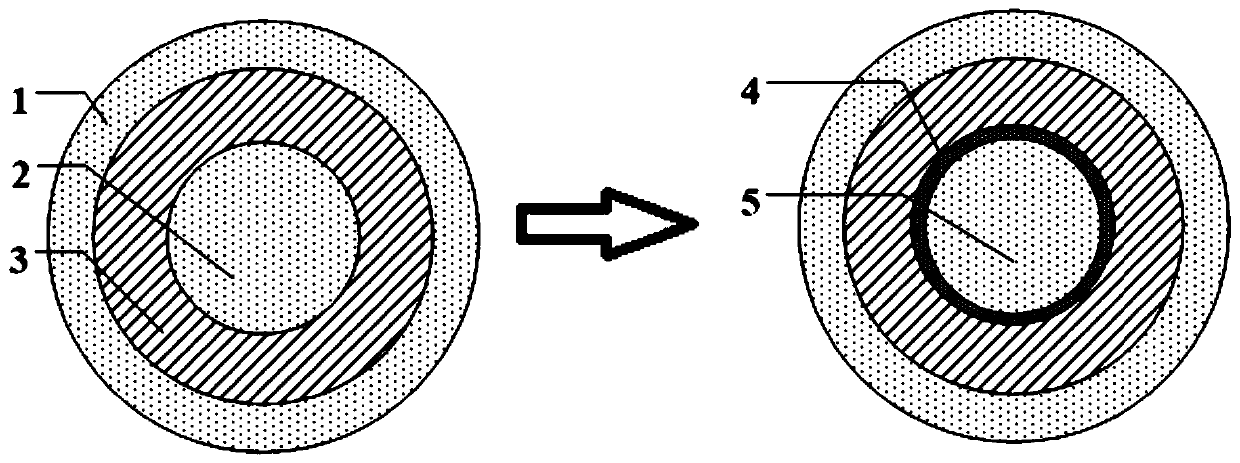

[0044] see figure 2 and image 3 , the preparation method of a kind of bimetallic metallurgy composite pipe of the present invention, comprises the following steps: according to the wall thickness requirement of bimetallic metallurgy composite pipe billet, process the water-cooled metal model of inner and outer layer metal pipe, first cast the outer wall metal pipe, wait for the outer wall After the layer tube is solidified, within a certain temperature, the inner layer metal tube is cast, and the structure of the water-cooled metal model of the bimetallic metallurgical composite tube and the structure of the tube blank are shown in figure 1 , which is characterized in that both ends of the tube blank are covered by inner metal. The solidified bimetallic metallurgical composite tube billet is hot-rolled, and the tube billet is heated again to 900 ℃ ~ 1200 ℃, and two rough rolling and one finishing rolling are carried out. The rolling temperature is controlled by the heating ...

Embodiment

[0059] A method for preparing a Φ139.7mm×9.17mm nickel-based alloy 625 / P110 bimetallic metallurgical composite pipe according to the embodiment of the present invention, the specific steps are as follows:

[0060] S1, processing water-cooled die-casting metal model: This model includes a hollow cylindrical metal mold with an inner diameter equal to the outer diameter of the bimetallic tube blank, and two metal mandrels with different diameters.

[0061] S2, Smelting: According to the chemical composition requirements of P110 carbon steel and nickel-based alloy 825, the two metals are smelted by electric arc furnace smelting and out-of-furnace refining.

[0062] S3, water-cooled die casting casting sequence: firstly put the large-diameter metal mandrel concentrically into the hollow cylindrical mold, and cast a certain amount of liquid nickel-based alloy 825 in a vacuum environment to ensure that the bottom of the outer carbon steel pipe is made of corrosion-resistant Alloy cla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com