Adaptive automatic control method for water treatment through magnetic medium coagulation and sedimentation

A technology of coagulation sedimentation and magnetic media, applied in sedimentation treatment, multi-stage water treatment, water/sewage treatment, etc., can solve safety production accidents, no unified industry standards or local standards for reference by industry insiders, waste, etc. problems, to achieve the effect of reducing labor intensity and facilitating automatic control and management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

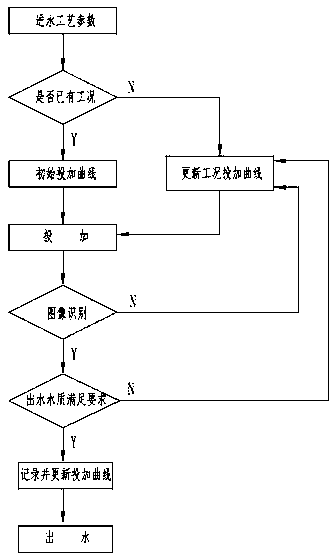

[0035] The self-adaptive magnetic medium coagulation sedimentation water treatment automatic control method of the present invention comprises the following steps:

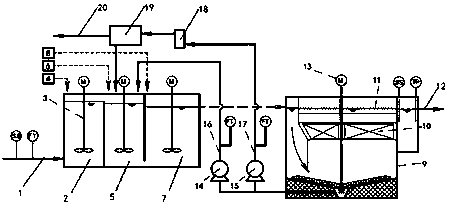

[0036] The first step is to build the system: First, connect each device through pipelines according to the design drawings, and connect each device to the controller to form a complete set of magnetic media coagulation and sedimentation system.

[0037] Magnetic media coagulation sedimentation system such as figure 1 Shown, comprise a reaction chamber, a settling tank 9 that are distributed side by side, there are two partition walls that divide the whole reaction chamber into a rapid mixing chamber 2, a magnetic medium mixing chamber 5, and a flocculation reaction chamber 7 that are distributed sequentially i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com