Foam concrete

A foamed concrete and foaming agent technology, applied in the field of foamed concrete, can solve the problems of affecting the compressive strength of foamed concrete, easy cracking of foamed concrete, etc., and achieve the effect of improving density and strong performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

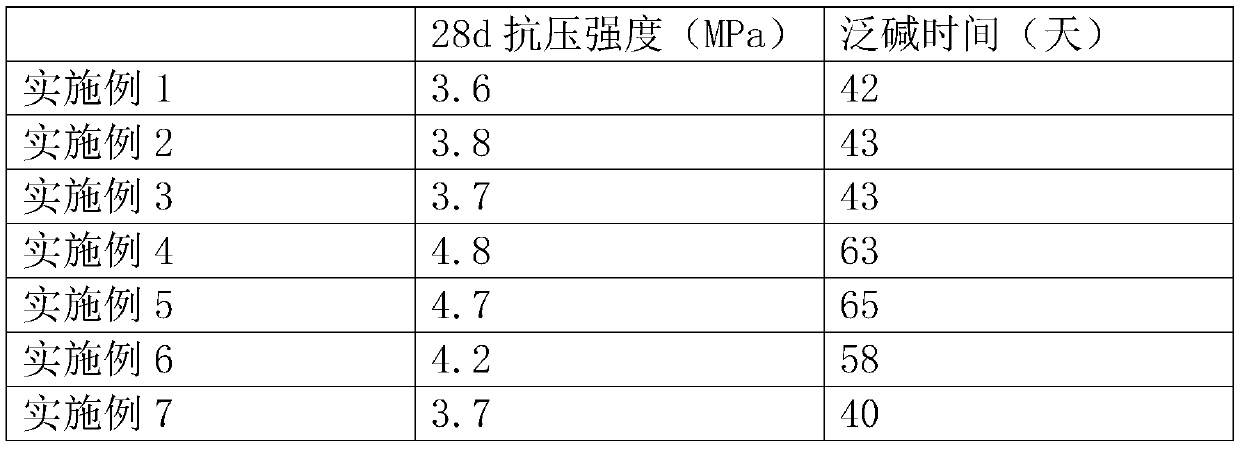

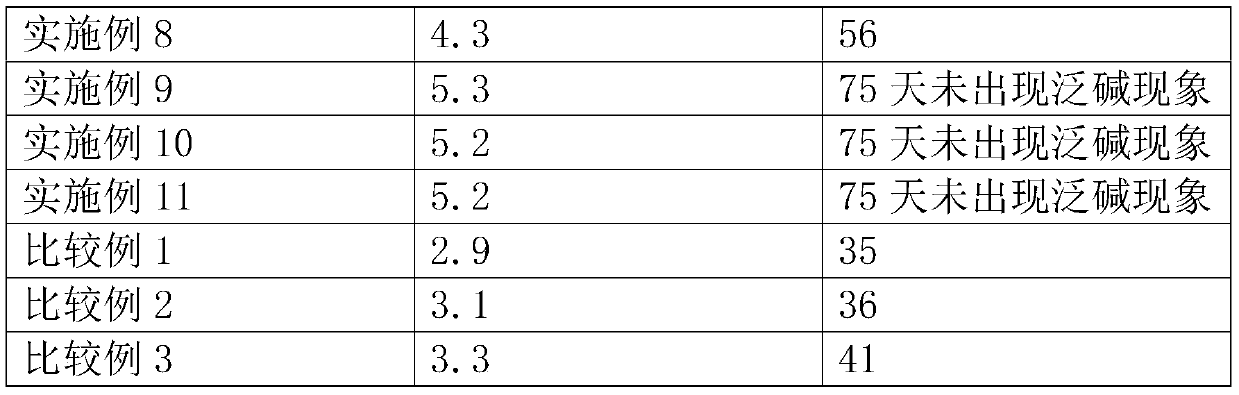

Examples

Embodiment 1

[0063] A foamed concrete including the following components in parts by mass:

[0064] Water 14kg; Portland cement 25kg; limestone powder 15kg; sand 75kg; stone 104.5kg; foaming agent 0.5kg; water reducing agent 0.5kg; starch 0.5kg; hollow glass beads 1kg; pineapple leaf fiber 0.3kg.

[0065] In this embodiment, the particle size of the hollow glass beads is 40 μm.

[0066] The preparation method of foam concrete is as follows:

[0067] S1. In a cement mixer, add 25kg of Portland cement under normal temperature conditions, and mix at a speed of 150r / min;

[0068] S2, while stirring, add 14 kg of water, 0.5 kg of water reducing agent, 0.5 kg of starch, 1 kg of hollow glass beads, and 0.3 kg of pineapple leaf fiber, and after stirring, a premix is obtained;

[0069] S3. In a sand-gravel mixer, under normal temperature conditions, add 15kg of limestone powder, 75kg of sand, and 104.5kg of stone, and stir at a speed of 180r / min to obtain aggregate after uniform mixing;

[0070] S4. In the c...

Embodiment 2

[0074] A foamed concrete including the following components in parts by mass:

[0075] Water 15kg; Portland cement 23kg; Limestone powder 11kg; Sand 85kg; Stone 103kg; Foaming agent 0.3kg; Water reducing agent 0.3kg; Starch 0.3kg; Hollow glass beads 0.5kg; Pineapple leaf fiber 0.1kg.

[0076] In this embodiment, the particle size of the hollow glass beads is 43 μm.

[0077] The preparation method of foam concrete is as follows:

[0078] S1. In the cement mixer, under normal temperature conditions, add 23kg of Portland cement and stir at a speed of 150r / min;

[0079] S2, while stirring, add 15kg of water, 0.3kg of water reducing agent, 0.3kg of starch, 0.5kg of hollow glass beads, and 0.1kg of pineapple leaf fiber. After stirring, a premix is obtained;

[0080] S3. In a sand-gravel mixer, under normal temperature conditions, add 11kg of limestone powder, 85kg of sand, and 103kg of stone, and stir at a speed of 180r / min to obtain aggregate after uniform mixing;

[0081] S4. In the concret...

Embodiment 3

[0085] A foamed concrete including the following components in parts by mass:

[0086] Water 16kg; Portland cement 20kg; Limestone powder 13kg; Sand 80kg; Stone 106kg; Foaming agent 0.4kg; Water reducing agent 0.4kg; Starch 0.4kg; Hollow glass beads 0.8kg; Pineapple leaf fiber 0.2kg.

[0087] In this embodiment, the particle size of the hollow glass beads is 45 μm.

[0088] The preparation method of foam concrete is as follows:

[0089] S1. In a cement mixer, add 20kg of Portland cement under normal temperature conditions, and stir at a speed of 150r / min;

[0090] S2, while stirring, add 16 kg of water, 0.4 kg of water reducing agent, 0.4 kg of starch, 0.8 kg of hollow glass beads, and 0.2 kg of pineapple leaf fiber. After stirring, a premix is obtained;

[0091] S3. In a sand-gravel mixer, under normal temperature conditions, add 13kg of limestone powder, 80kg of sand, and 106kg of stone, and stir at a speed of 180r / min to obtain aggregate after uniform mixing;

[0092] S4. In the conc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com