Method for producing high-performance aluminum alloy plate strip through sheet billet continuous roll casting

A technology for aluminum alloy strips and thin slabs, applied in metal rolling and other directions, can solve the problems of low yield, large composition difference, uneven microstructure, etc., to improve processing performance, reduce energy consumption, and improve material utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

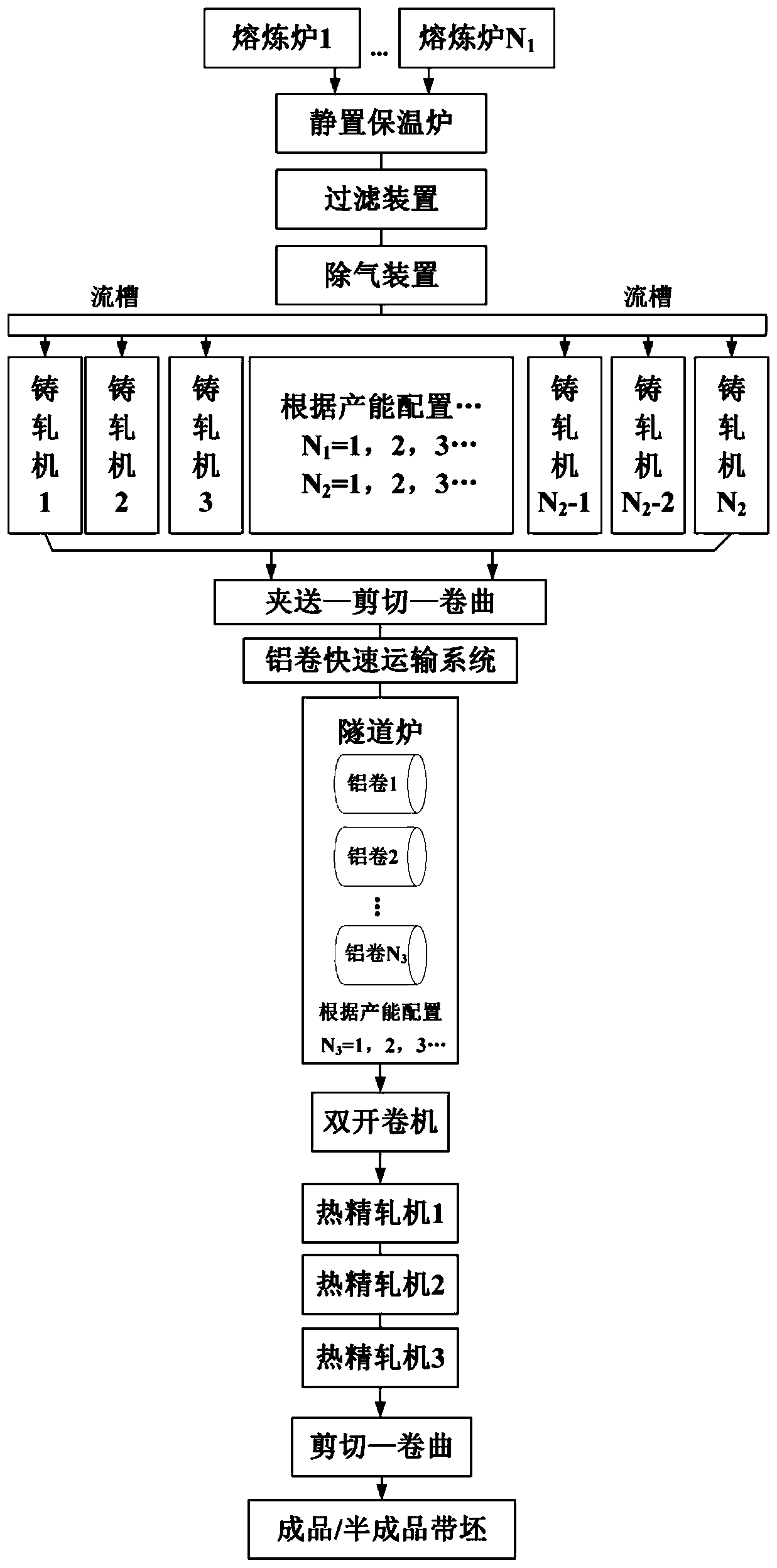

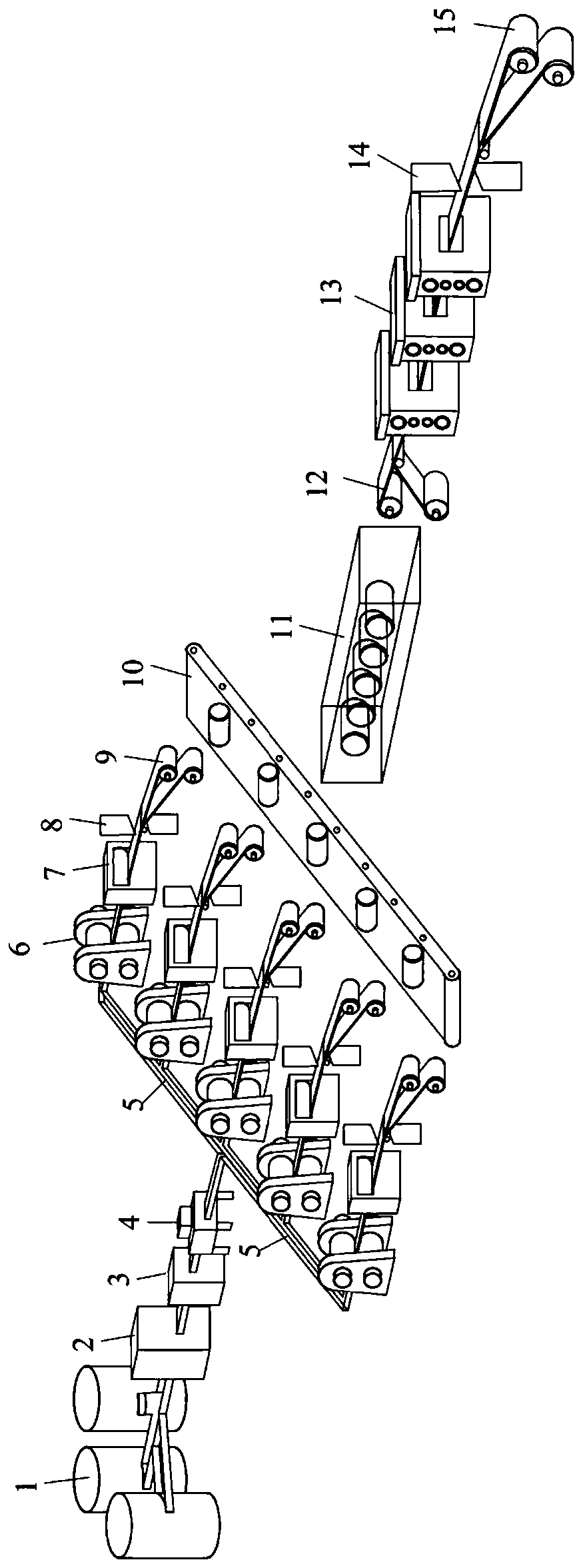

[0040] An industrialized production line arrangement for the production of high-performance aluminum alloy plates and strips by continuous casting and rolling of thin slabs, such as figure 1 Shown: Melting Furnace Static Holding Furnace-Filtration Device-Degassing Device-Launder-Continuous Casting Roller-Pinch Roller-Slitting Machine-Coiler-Aluminum Coil Rapid Transport System-Tunnel Furnace-Uncoiler-Three Racks Hot continuous rolling mill-shearing machine-coiler, according to the production capacity configuration, there can be multiple continuous casting and rolling production lines; the corresponding equipment structure diagram is as follows figure 2As shown, it includes: aluminum alloy smelting furnace 1, static holding furnace 2, filter box 3, degassing box 4, launder 5, continuous casting and rolling machine 6, pinch roll 7, first dividing shear 8, first double Coiler 9, fast delivery roller table 10, tunnel furnace 11, double uncoiler 12, three-stand hot continuous roll...

Embodiment 2

[0053] In this embodiment, the process and method for producing aluminum alloy sheets by continuous casting and rolling combined with continuous hot rolling for 1100 aluminum alloy thin slabs utilizes the device in embodiment 1, and the specific steps are as follows:

[0054] (1) Smelting and refining:

[0055] According to the standard composition of 1100 aluminum alloy, by weight percentage (wt%) (Si+Fe): 0.95, Cu: 0.05-0.20, Zn: 0.10, Mn: 0.035, Al: balance. Industrial pure aluminum, aluminum-silicon, aluminum-copper and other intermediate alloys are weighed in equal proportions and put into a melting furnace for melting. After all the industrial pure aluminum ingots are melted first, then the above-mentioned intermediate alloys are added in turn, and the molten aluminum is transferred to a heat preservation and static furnace for standing. When the temperature of the molten aluminum in the static furnace is 710°C, the melt is purified. The above-mentioned melt purificatio...

Embodiment 3

[0068] This embodiment is aimed at 3003 aluminum alloy thin slabs, and the continuous casting and rolling combined with hot continuous rolling is used to produce aluminum alloy sheets. The device in embodiment 1 is used. The specific steps are as follows:

[0069] (1) Smelting and refining:

[0070] According to the standard composition of 3003 aluminum alloy (wt%) Si: 0.6, Cu: 0.1, Zn: 0.1, Mn: 1.2, Fe: 0.7, Al: balance, industrial pure aluminum, aluminum silicon, aluminum copper and other intermediate alloys, etc. Proportional weighing, put into the melting furnace for smelting, after the aluminum ingots are completely melted, add the above-mentioned intermediate alloys in turn, transfer the aluminum water to the heat preservation static furnace for standing, when the temperature of the aluminum water in the static furnace is 710-750 ℃, the melt purification treatment is carried out. The melt purification treatment specifically refers to the use of SNIF rotary jet degassing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com