Method for detecting degradation condition of mulching film source micro-plastics in soil

A detection method and technology of microplastics, which are applied in the directions of measuring devices, analytical materials, color/spectral characteristics measurement, etc., can solve the problem of the inability to obtain the physical information of microplastic particle size, shape, and surface morphology characteristics, and the inability to visually see microplastics Surface degradation and other issues, to achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Degradation experiment

[0028] Set the concentration of the butylene adipate copolymer mulch film source microplastics in the soil to 1%, and disperse them evenly in the soil. In an incubator at 24±1°C, under 4500 lx irradiation, 12:12 hours light:dark cycle every day, to simulate the degradation behavior in the environment. The soil uses OECD standard soil: the main characteristics are 69.5% sand, 20% kaolin, 10% peat moss, 0.5% CaCO 3 . After the standard soil is sieved with 80 meshes, its water content is controlled at 20%-25%.

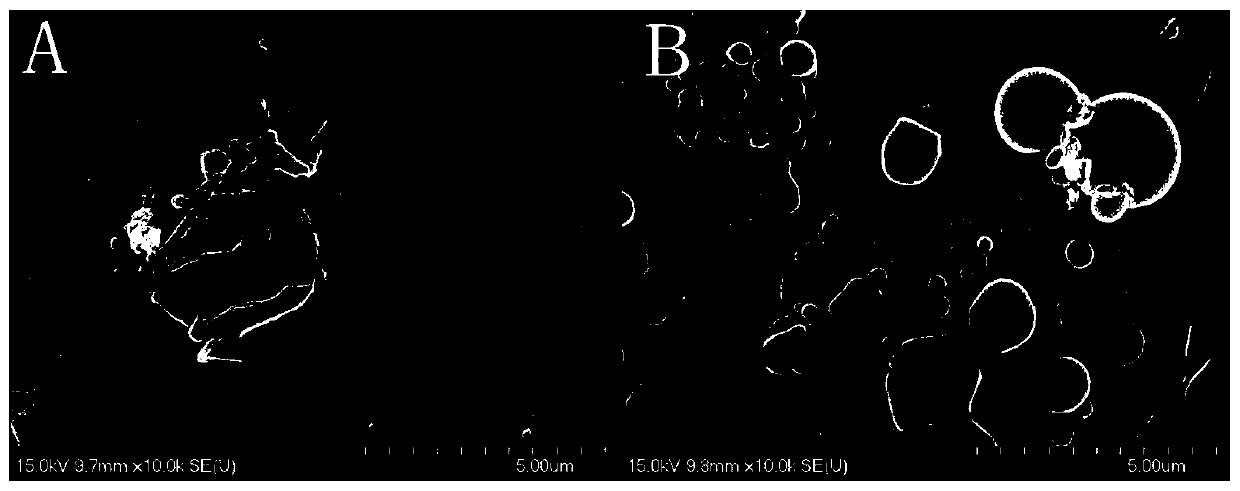

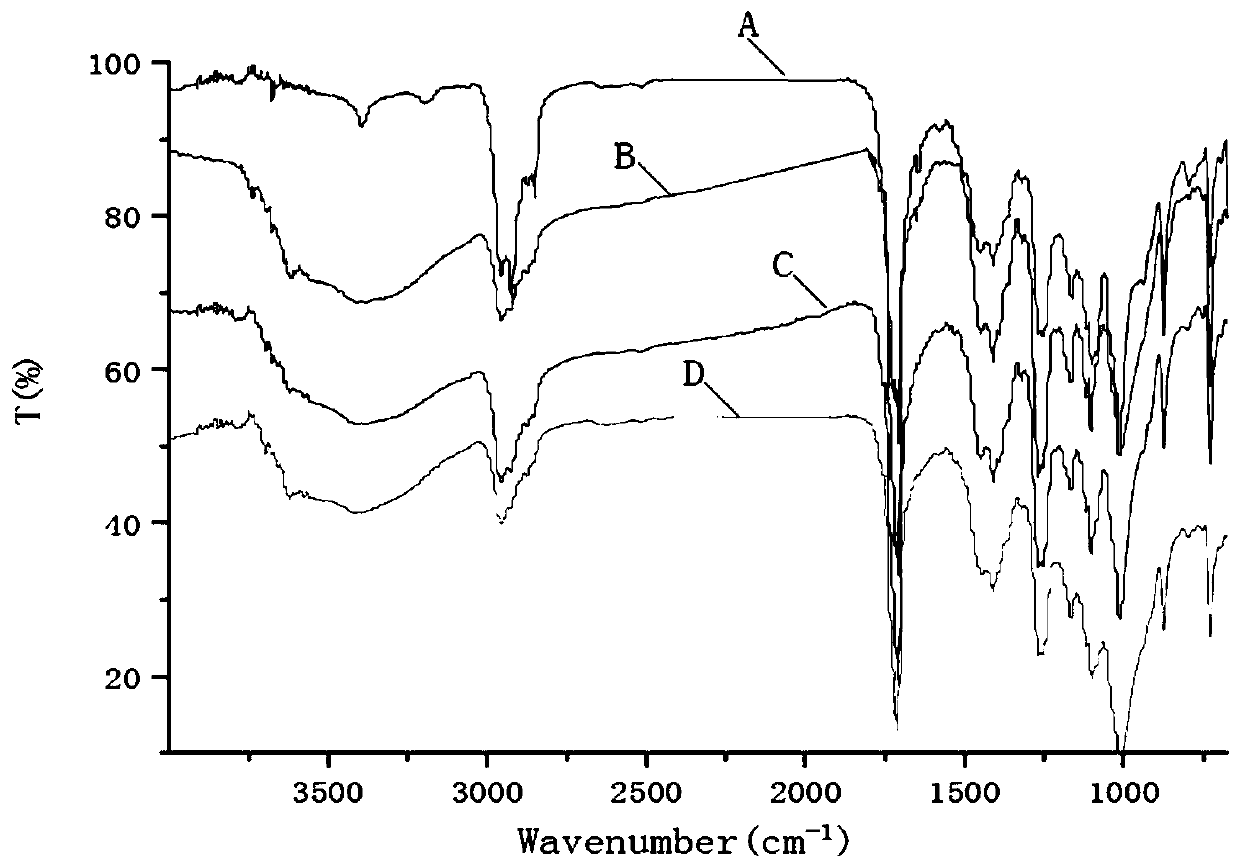

[0029] (2) Separation and extraction of plastic film source microplastics

[0030] Take 10g of the degraded soil and dry it with a sieve to remove microplastics with larger particle sizes, then transfer the sieved soil to a saturated NaCl solution, shake it sufficiently to suspend the microplastics in the solution, and let it stand to suspend The solution was layered with the soil solids, and then the solution suspended with mulch-d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com