HTPP nucleating agent, preparation process and application thereof in preparation of heatproof and impact-resistant HTPP

A preparation process and nucleating agent technology, which is applied in the field of HTPP nucleating agent, can solve the problems of heat deformation resistance reduction, etc., and achieve the effects of high heat resistance deformation temperature, stable performance index, and fast crystallization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

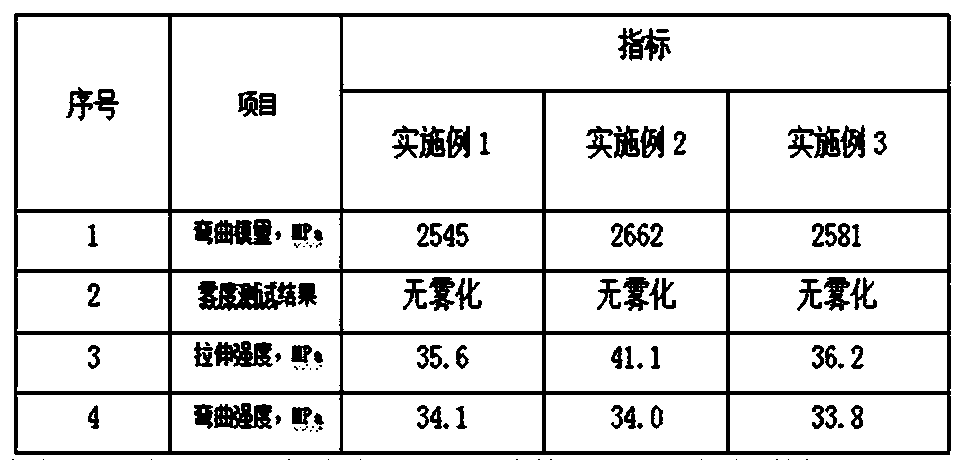

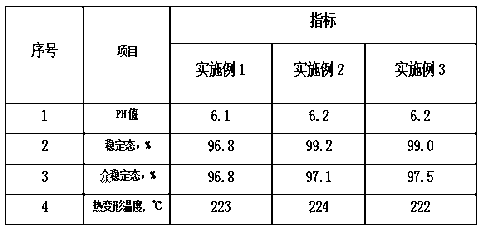

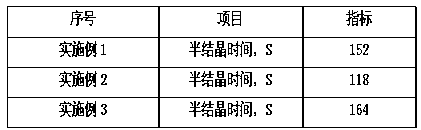

Embodiment 1

[0032] Example 1 A preparation process of HTPP nucleating agent

[0033] The preparation process of an HTPP nucleating agent of the present invention includes the following steps:

[0034] (1) Raw material preparation:

[0035] The raw materials include melamine and its melamine salt, polyvinyl-2-methylcyclohexane, 1,3,5-tri-tert-butyramidobenzene, 2-pyridinethiol-1-zinc oxide and abietic acid parent grain;

[0036] In parts by weight, the raw materials include 0.01 part of melamine and its melamine salt, 50 parts of polyvinyl-2-methylcyclohexane, 1 part of 1,3,5-tri-tert-butyramidobenzene, and 2-pyridinethiol -1- 2 parts of zinc oxide, 25 parts of rosin acid masterbatch.

[0037] The melamine salt is a melamine salt formed by melamine and cyanuric acid, hydrochloric acid, sulfuric acid, nitric acid, acetic acid, and oxalic acid;

[0038] The rosin acid masterbatch is a co-crystal of dehydroabietic acid, potassium dehydroabietic acid and sodium dehydroabietic acid, and the mass ratio i...

Embodiment 2

[0047] Example 2 A preparation process of HTPP nucleating agent

[0048] The preparation process of an HTPP nucleating agent of the present invention includes the following steps:

[0049] (1) Raw material preparation:

[0050] The raw materials include melamine and its melamine salt, polyvinyl-2-methylcyclohexane, 1,3,5-tri-tert-butyramidobenzene, 2-pyridinethiol-1-zinc oxide and abietic acid parent grain;

[0051] In parts by weight, the raw materials include 0.06 parts of melamine and its melamine salt, 35 parts of polyvinyl-2-methylcyclohexane, 5 parts of 1,3,5-tri-tert-butyramidobenzene, and 2-pyridinethiol -1-0.7 parts of zinc oxide, 33 parts of rosin acid masterbatch.

[0052] The melamine salt is a melamine salt formed by melamine and cyanuric acid, hydrochloric acid, sulfuric acid, nitric acid, acetic acid, and oxalic acid;

[0053] The rosin acid masterbatch is a co-crystal of dehydroabietic acid, potassium dehydroabietic acid and sodium dehydroabietic acid, and the mass rati...

Embodiment 3

[0062] Example 3 A preparation process of HTPP nucleating agent

[0063] The preparation process of an HTPP nucleating agent of the present invention includes the following steps:

[0064] (1) Raw material preparation:

[0065] The raw materials include melamine and its melamine salt, polyvinyl-2-methylcyclohexane, 1,3,5-tri-tert-butyramidobenzene, 2-pyridinethiol-1-zinc oxide and abietic acid parent grain;

[0066] In parts by weight, the raw materials include 1 part of melamine and its melamine salt, 20 parts of polyvinyl-2-methylcyclohexane, 8 parts of 1,3,5-tri-tert-butyramidobenzene, and 2-pyridinethiol -1- 0.1 part of zinc oxide, 50 parts of rosin acid masterbatch.

[0067] The melamine salt is a melamine salt formed by melamine and cyanuric acid, hydrochloric acid, sulfuric acid, nitric acid, acetic acid, and oxalic acid;

[0068] The rosin acid masterbatch is a co-crystal of dehydroabietic acid, potassium dehydroabietic acid and sodium dehydroabietic acid, and the mass ratio is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com