Method of applying cleaning machine to quickly preheating tableware

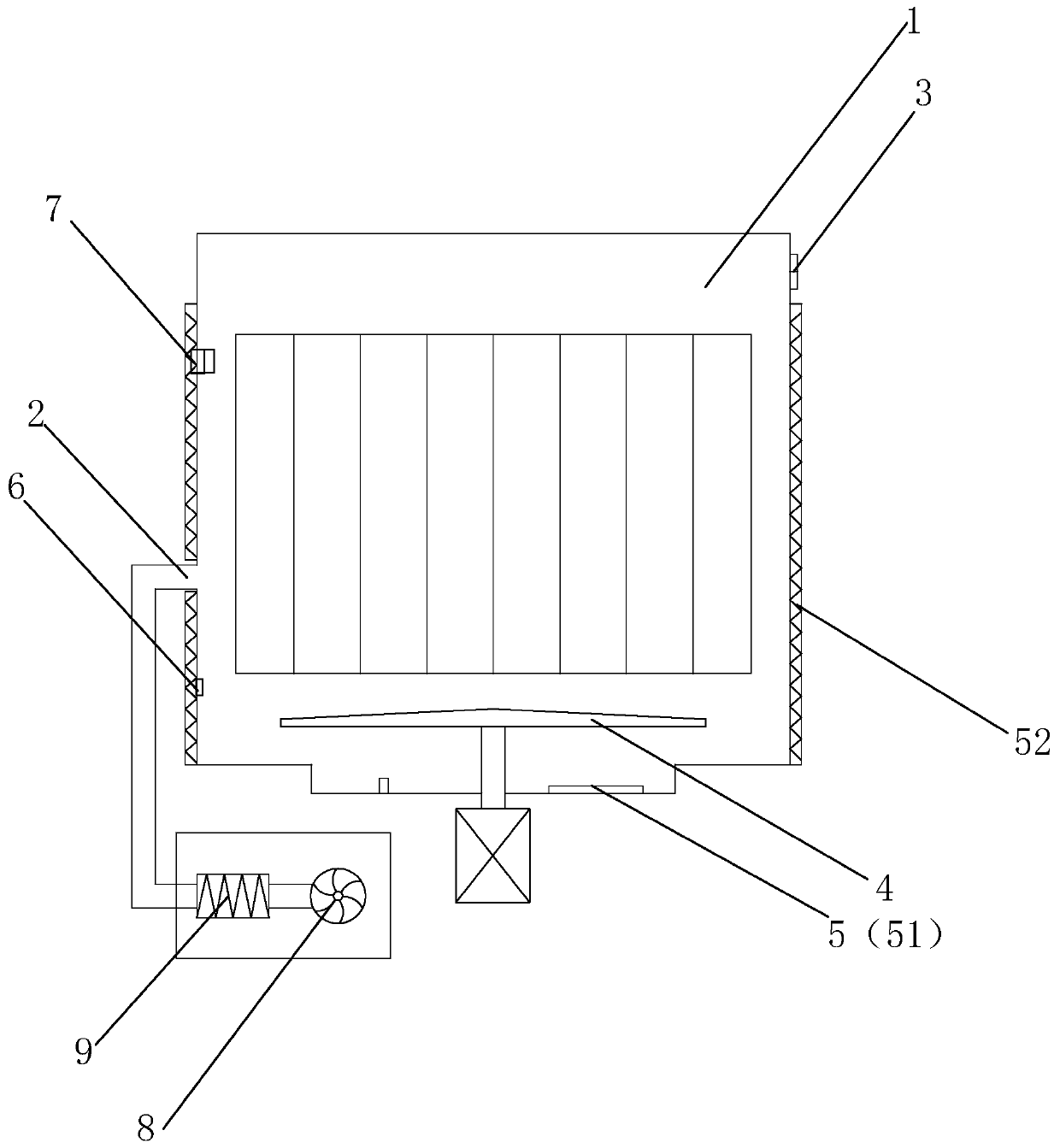

A technology for washing machines and tableware, applied in the field of preheating tableware, can solve the problems of water residue in dishwashers, tableware not completely dry, tableware is cold, etc., and achieves the effects of improving safety, shortening heating time, and short preheating time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The method for rapidly preheating tableware in the present embodiment comprises the following steps:

[0030] (1) Washing heating step, comprising:

[0031] Step A, start the cleaning machine, open the water inlet valve, and inject water into the cleaning chamber 1. When the water inlet volume reaches 3L and the preset value (time), the control system controls the solenoid valve to close, and stops water injection;

[0032] Step B, start the washing pump and the heating plate at the same time, and use the flushing water flow formed by the spray assembly 4 to wet the surface of the tableware; in order to achieve the purpose of quickly preheating the tableware, generally the washing pump can be turned on for one minute to make the surface of the tableware wet. Wet well. The washing pump and the heating device 5 can be started synchronously; the washing pump can also be turned on first, and the dishes to be heated are rinsed for more than ten seconds to make the surface o...

Embodiment 2

[0040] The method for rapidly preheating tableware in the present embodiment comprises the following steps:

[0041] (1) Washing heating step, comprising:

[0042] Step A, start the cleaning machine, the controller controls the ultraviolet sterilizing device 7, the water inlet valve is opened, and water is injected into the cleaning chamber 1. When the water inlet reaches 5L (time 20S), the control system controls the solenoid valve to close, and the water injection is stopped;

[0043] Step B, first turn on the washing pump, rinse the dishes to be heated for more than ten seconds to fully wet the surface of the dishes, and then turn on the heating plate.

[0044] Step C, when the temperature detection element 6 detects that the temperature in the cleaning chamber 1 reaches 50°C, the control system controls the heating plate to stop heating;

[0045] Step D, the control system controls the washing pump to stop working, the drain valve of the drain assembly is opened, and the ...

Embodiment 3

[0051] The method for rapidly preheating tableware in the present embodiment comprises the following steps:

[0052] (1) Washing heating step, comprising:

[0053] Step A, start the cleaning machine, the controller controls the ultraviolet sterilizing device 7, the water inlet valve is opened, and water is injected into the cleaning chamber 1. When the water inlet reaches 8L (time 35S), the control system controls the solenoid valve to close, and the water injection is stopped;

[0054]Step B, first turn on the washing pump, rinse the dishes to be heated for more than ten seconds to fully wet the surface of the dishes, and then turn on the heating plate.

[0055] Step C, when the temperature detection element 6 detects that the temperature in the cleaning chamber 1 reaches 70°C, the control system controls the heating plate to stop heating;

[0056] Step D, the control system controls the washing pump to stop working, the drain valve of the drain assembly is opened, and the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com