Copper-containing antibacterial self-cleaning coating, preparation method and application thereof

A self-cleaning coating and substrate technology, applied in coatings, metal material coating processes, and devices for coating liquid on the surface, can solve the problems of single antibacterial function of products, long preparation cycle, high equipment requirements, etc., and achieve production Low cost, prevention of microbial adhesion and corrosion, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

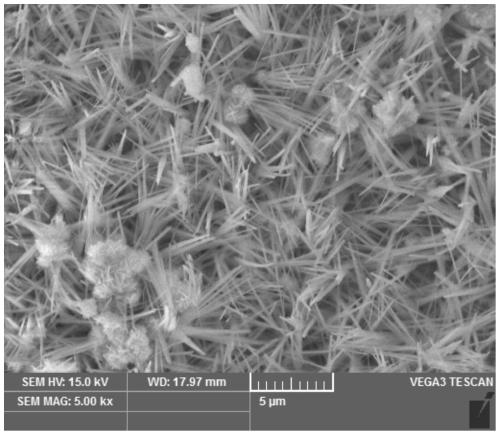

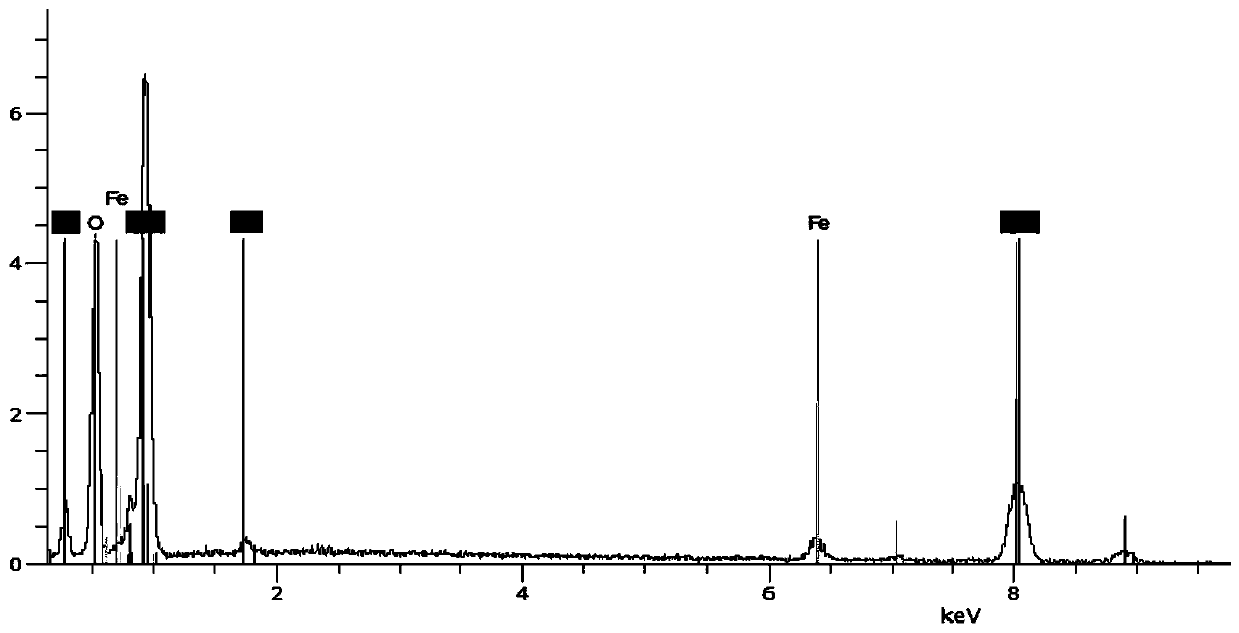

Image

Examples

Embodiment 1

[0029] The preparation method of copper-containing antibacterial self-cleaning coating of the present invention comprises:

[0030] (1) After grinding and polishing the substrate, immerse it in the copper-containing processing fluid and deposit it at room temperature for 20s; wherein, the copper-containing processing fluid includes CuSO 4 ·5H 2 O, potassium sodium tartrate, glucose and OP-10; among them, CuSO 4 ·5H 2 The concentration of O is 0.1mol / L; the concentration of potassium sodium tartrate is 0.05mol / L; the concentration of glucose is 0.1mol / L; the concentration of OP-10 is 0.01g / L.

[0031] (2) Submerge the deposited substrate in an alkaline processing solution for 20 minutes at room temperature; wherein, the alkaline processing solution includes: NaOH and (NH 4 ) 2 S 2 o 8 ; Wherein the concentration of NaOH is 1mol / L, (NH 4 ) 2 S 2 o 8 The concentration is 0.1mol / L.

[0032] (3) Submerge the alkaline-treated substrate in a modification solution for 1 hou...

Embodiment 2

[0035] The preparation method of copper-containing antibacterial self-cleaning coating of the present invention comprises:

[0036] (1) After grinding and polishing the substrate, immerse it in the copper-containing processing fluid and deposit it at room temperature for 1 min; wherein, the copper-containing processing fluid includes CuSO 4 ·5H 2 O, potassium sodium tartrate, glucose and OP-10; among them, CuSO 4 ·5H 2 The concentration of O is 0.5mol / L; the concentration of potassium sodium tartrate is 0.1mol / L; the concentration of glucose is 0.3mol / L; the concentration of OP-10 is 0.05g / L.

[0037] (2) Submerge the deposited substrate in an alkaline processing solution for 50 minutes at room temperature; wherein, the alkaline processing solution includes: NaOH and (NH 4 ) 2 S 2 o 8 ; Wherein the concentration of NaOH is 5mol / L, (NH 4 ) 2 S 2 o 8 The concentration is 1mol / L.

[0038] (3) Submerge the alkaline-treated substrate in a modification solution for 3 hour...

Embodiment 3

[0041] The preparation method of copper-containing antibacterial self-cleaning coating of the present invention comprises:

[0042] (1) After grinding and polishing the substrate, immerse it in the copper-containing processing fluid and deposit it at room temperature for 20s-5min; wherein, the copper-containing processing fluid includes CuSO 4 ·5H 2 O, potassium sodium tartrate, glucose and OP-10; among them, CuSO 4 ·5H 2 The concentration of O is 1mol / L; the concentration of potassium sodium tartrate is 0.15mol / L; the concentration of glucose is 0.5mol / L; the concentration of OP-10 is 1g / L.

[0043] (2) Submerge the deposited substrate in an alkaline processing solution for 80 minutes at room temperature; wherein, the alkaline processing solution includes: NaOH and (NH 4 ) 2 S 2 o 8 ; Wherein the concentration of NaOH is 10mol / L, (NH 4 ) 2 S 2 o 8 The concentration is 2mol / L.

[0044] (3) Submerge the alkaline-treated substrate in a modification solution for 5 hour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com