PVC transfer printing composite tablecloth and manufacturing method thereof

A technology of transfer printing and PVC film, applied in the field of tablecloth, can solve the problems of hot indentation, discoloration, fading, etc., and achieve the effect of good water and alkali resistance, improved service life and firm surface pattern

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

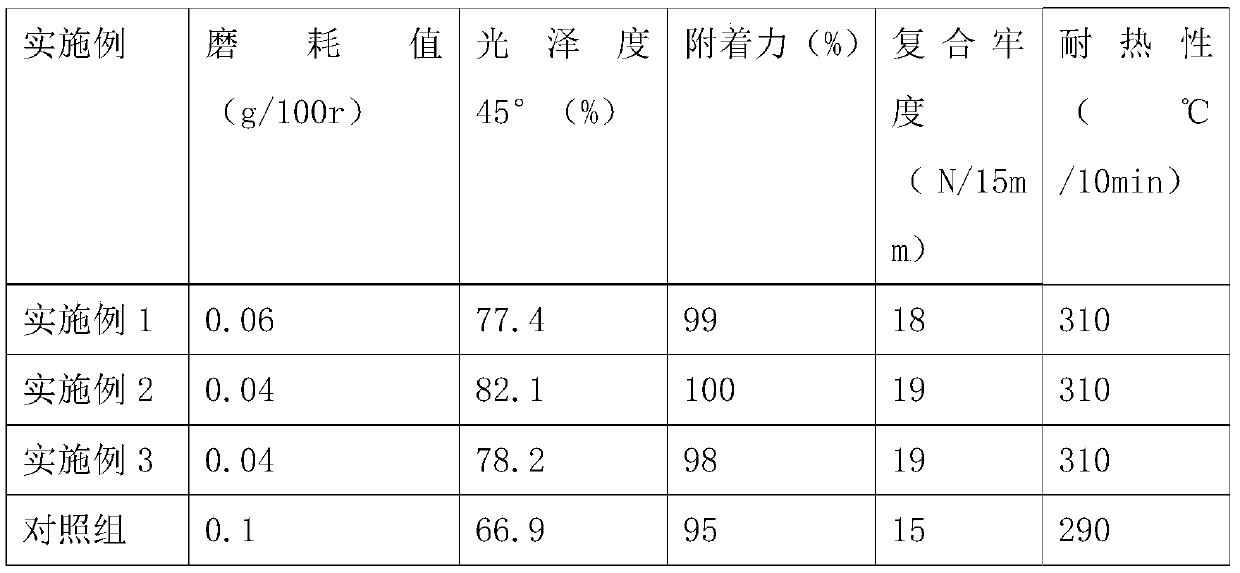

Examples

Embodiment 1

[0031] A PVC transfer printing composite tablecloth, comprising a base cloth layer, a middle PVC film layer, a surface PVC film layer and an ink layer;

[0032] The base fabric layer adopts non-woven fabric.

[0033] According to parts by weight, the raw materials of the middle PVC film layer are: 100 parts of PVC resin, 30 parts of plasticizer, 5 parts of heat stabilizer, 4 parts of antioxidant, and 6 parts of intermediate functional additives;

[0034] The intermediate functional additives are 3 parts of soybean oil, 1 part of titanium dioxide, 1 part of benzyl silicone oil, 4 parts of urea-formaldehyde resin and 2 parts of styrene-acrylic emulsion.

[0035] The urea-formaldehyde resin improves the viscosity of the middle PVC film layer, and the addition of phenylmethyl silicone oil increases the waterproofness and viscosity of the middle PVC film layer, prevents the peeling of the surface PVC film layer, and the addition of titanium dioxide has a certain effect on the middl...

Embodiment 2

[0046] The technical solution of this embodiment is basically the same as that of Embodiment 1, and the similarities will not be repeated, and the difference is:

[0047] A PVC transfer printing composite tablecloth, comprising a base cloth layer, a middle PVC film layer, a surface PVC film layer and an ink layer;

[0048] According to parts by weight, the raw materials of the middle PVC film layer are: 100 parts of PVC resin, 40 parts of plasticizer, 10 parts of heat stabilizer, 8 parts of antioxidant, and 12 parts of intermediate functional auxiliary agent;

[0049] The raw materials of the surface PVC film layer are: 100 parts of PVC resin, 60 parts of plasticizer, 6 parts of heat stabilizer, 8 parts of antioxidant, and 12 parts of surface functional additive;

[0050] The raw materials of the ink layer are: 100 parts of polyurethane resin, 10 parts of antioxidant, 10 parts of defoamer, 8 parts of silicone leveling agent, 15 parts of colorant and 12 parts of ink functional ...

Embodiment 3

[0055] A PVC transfer printing composite tablecloth, in parts by weight, the raw materials of the middle PVC film layer are: 100 parts of PVC resin, 35 parts of plasticizer, 6.5 parts of heat stabilizer, 5 parts of antioxidant, and 8 parts of intermediate functional additives;

[0056] The raw materials of the surface PVC film layer are: 100 parts of PVC resin, 54 parts of plasticizer, 5 parts of heat stabilizer, 6 parts of antioxidant, and 8 parts of surface functional additive;

[0057]The raw materials of the ink layer are: 100 parts of polyurethane resin, 7 parts of antioxidant, 7 parts of defoamer, 6 parts of silicone leveling agent, 12 parts of colorant and 8 parts of ink functional additive.

[0058] The intermediate functional additives are 4 parts of soybean oil, 1.3 parts of titanium dioxide, 2 parts of benzyl silicone oil, 5 parts of urea-formaldehyde resin and 3 parts of styrene-acrylic emulsion;

[0059] The surface functional additives are 4 parts of anti-wear ag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com