Antistatic fireproof composite material, preparation method thereof and semiconductor equipment

A composite material and anti-static technology, which is applied in the field of composite materials, can solve the problems of incompatibility of fire resistance and anti-static performance, and achieve the effect of good fire resistance, good anti-static performance and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0050] As an optional embodiment of the present invention, the conductive agent includes graphene and / or graphene oxide.

[0051] Both graphene and graphene oxide have good electrical conductivity. Adding them to resin or polymer materials can make the resin or polymer materials have a certain degree of electrical conductivity so that the negative charges on their surface can be dissipated and given to them. Contact materials, thereby improving the antistatic performance of the resin or polymer material, and graphene and / or graphene oxide can also endow the resin or polymer material with excellent mechanical properties.

[0052] As an optional embodiment of the present invention, the mass ratio of magnesium hydroxide, glass powder, melamine cyanurate and zinc phosphate in the flame retardant is (5-15): (5-15): (0.5-2 ): (1-7), preferably (6-14): (6-14): (0.6-1.8): (1.5-6), more preferably (8-12): (8-12): ( 0.8-1.5): (2-5).

[0053] Typical but non-limiting mass ratios of mag...

Embodiment 1

[0094] This embodiment provides an antistatic refractory composite material, which is mainly made of the following raw materials in parts by weight:

[0095] 90 parts of epoxy resin, 5 parts of curing agent, 0.2 parts of conductive agent and 10 parts of flame retardant;

[0096]Wherein, the epoxy resin is epoxy resin E44, its epoxy value is 0.44eq / 100g, and its viscosity at 25°C is 30000cP;

[0097] The conductive agent is graphene oxide, the curing agent is ethylenediamine, and the flame retardant includes magnesium hydroxide, glass powder, melamine cyanurate and zinc phosphate, and the mass ratio of the four is 5:5:0.5:1.

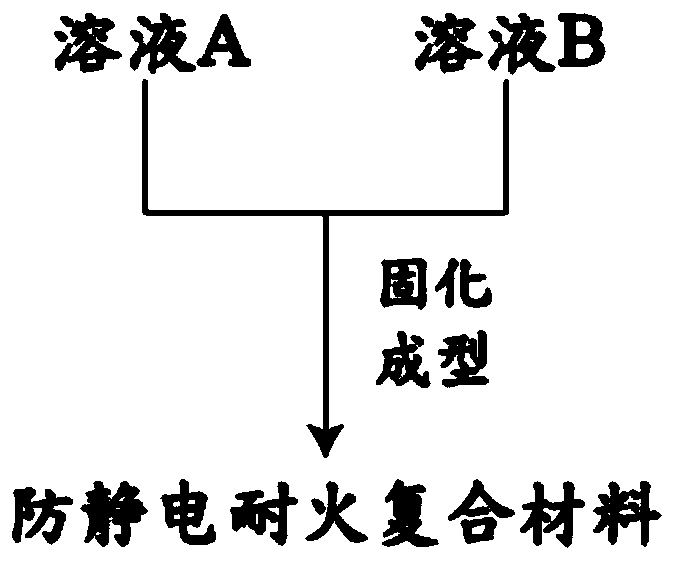

[0098] The preparation method of the antistatic refractory composite material provided in this embodiment comprises the following steps:

[0099] Provide solution A formed by flame retardant and curing agent;

[0100] Add solution A to solution B formed by mixing graphene oxide and epoxy resin, stir quickly and prevent bubbles, the stirring speed is 120...

Embodiment 2

[0102] This embodiment provides an antistatic refractory composite material, which is mainly made of the following raw materials in parts by weight:

[0103] 92 parts of epoxy resin, 6 parts of curing agent, 0.25 parts of conductive agent and 12 parts of flame retardant;

[0104] Wherein, the epoxy resin is epoxy resin E44, its epoxy value is 0.44eq / 100g, and its viscosity at 25°C is 30000cp;

[0105] The conductive agent is graphene oxide, the curing agent is ethylenediamine, and the flame retardant includes magnesium hydroxide, glass powder, melamine cyanurate and zinc phosphate, and the mass ratio of the four is 5:5:0.5:1.

[0106] The preparation method of the antistatic refractory composite material provided in this example is the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com