Scanning type laser shock peening device

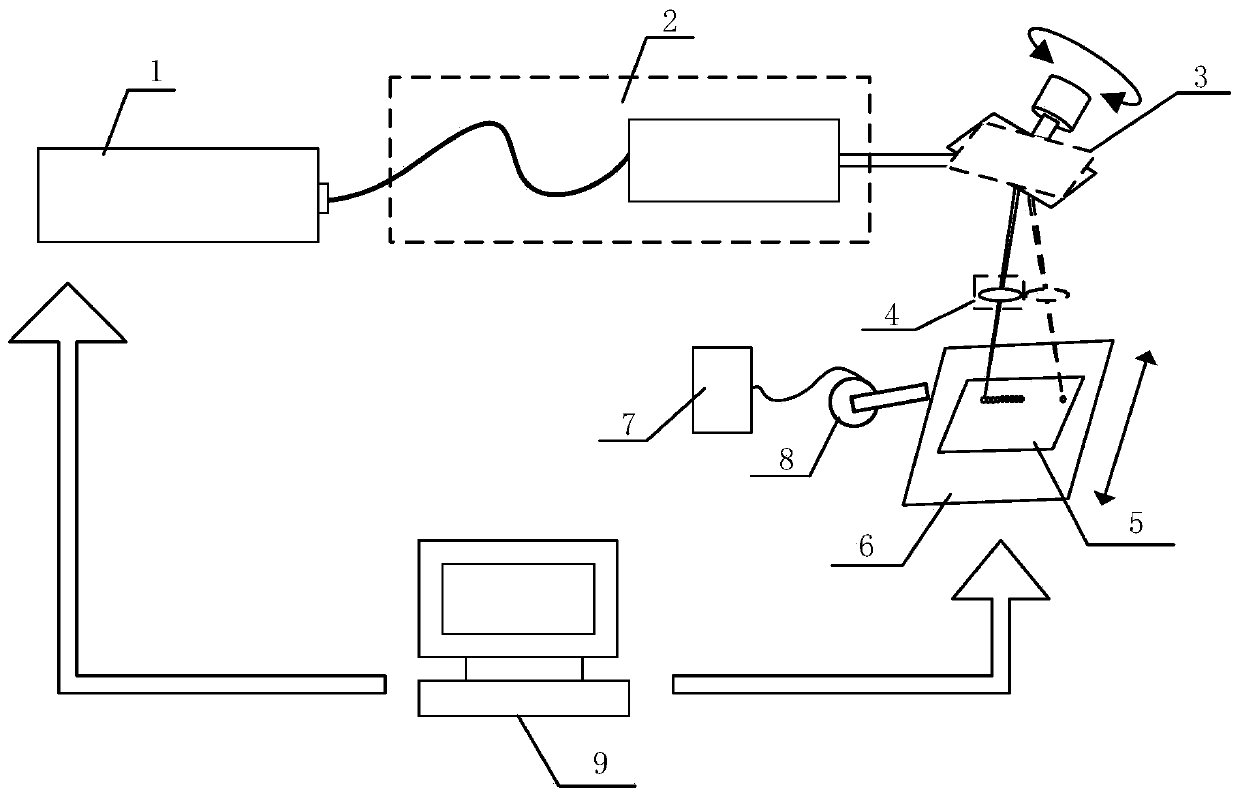

A laser shock strengthening and scanning technology, which is applied in the field of metal surface treatment, can solve the problems of low efficiency of laser shock strengthening, achieve the effect of facilitating laser shock strengthening processing, facilitating laser shock strengthening processing, and improving matching and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

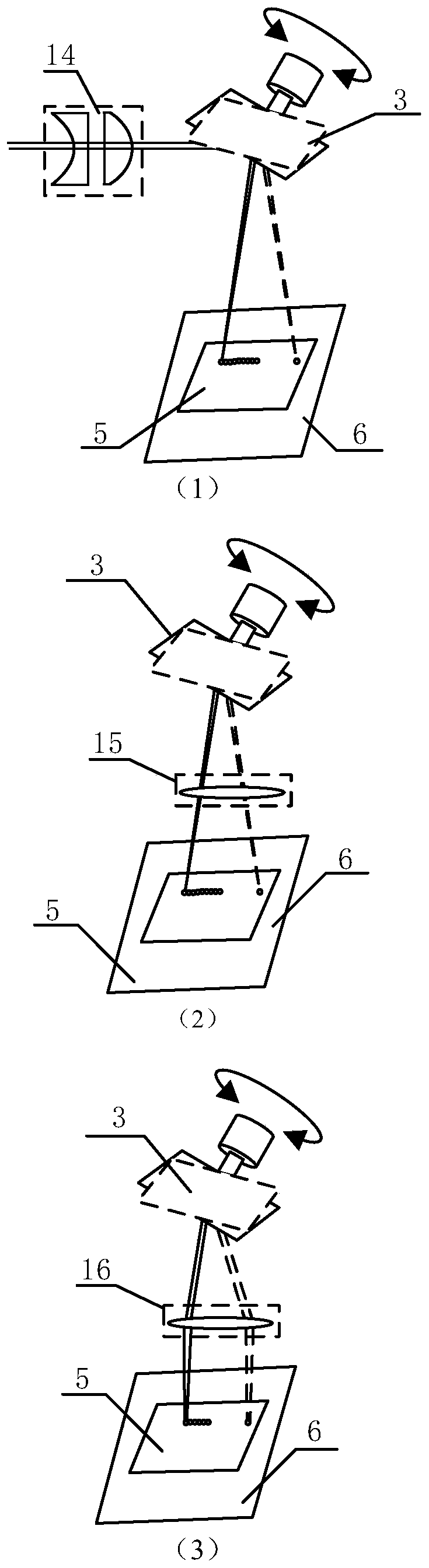

[0042] A scanning laser shock peening device in this embodiment has basically the same structure as that in Embodiment 1, the difference is that:

[0043] The focusing device 4 is arranged on the output (reflection) laser light path of the one-dimensional scanning galvanometer 3, such as image 3 (2) shown.

Embodiment 3

[0045] A scanning laser shock peening device in this embodiment has basically the same structure as that in Embodiment 1, the difference is that:

[0046] The focusing device 4 adopts a telecentric field mirror 16, which is arranged on the output (reflection) laser light path of the one-dimensional scanning vibrating mirror 3, such as image 3 (3) shown.

Embodiment 4

[0048] A scanning laser shock peening device in this embodiment has basically the same structure as that in Embodiment 1, the difference is that:

[0049] Laser 1 adopts a low repetition frequency and high energy laser below 50 Hz.

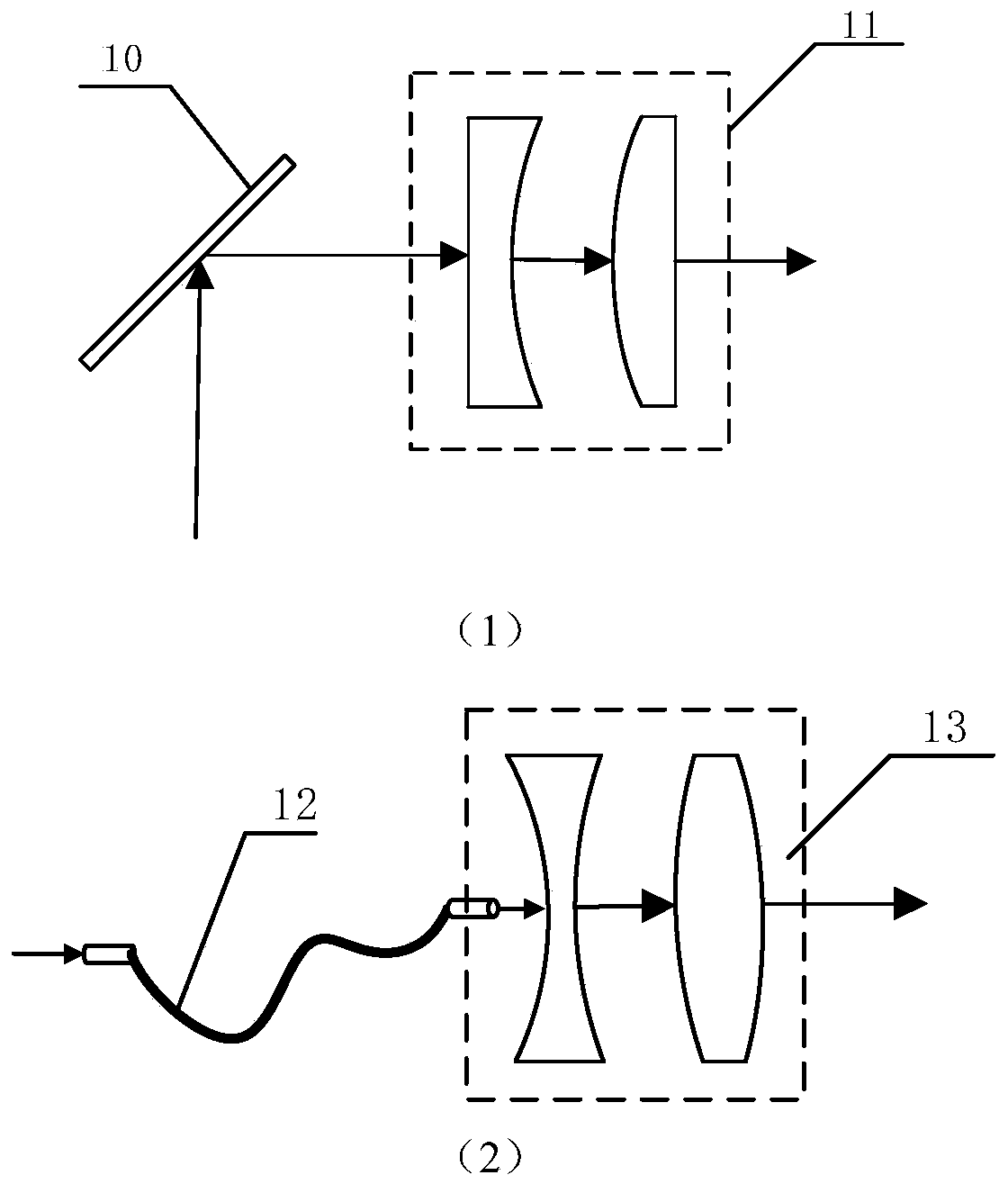

[0050] Such as figure 2 As shown in (2), the light guide device 2 adopts an optical fiber 12 or other flexible light guide device, and the optical fiber 12 cooperates with the optical fiber transmission shaping device 13 to shape and transmit the laser output from the laser 1 .

[0051] The focusing device 4 adopts an ordinary focusing mirror, which is arranged on the optical path between the one-dimensional scanning vibrating mirror 3 and the metal part 5 , and moves and deflects together with the one-dimensional scanning vibrating mirror 3 .

[0052] The water constrained layer loading device 8 is a movable structure.

[0053] The laser 1 , light guiding device 2 , one-dimensional scanning galvanometer 3 , focusing device 4 , moving clamping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com