Landfill type electrode structure suitable for surface acoustic wave device

A surface acoustic wave device and electrode structure technology, applied to electrical components, impedance networks, etc., can solve problems that cannot be used in high temperature environments, melting and recondensation, long-term operation of electrodes, etc., to increase stable working time and improve reflection coefficient and electromechanical coupling coefficient, the effect of improving pressure sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

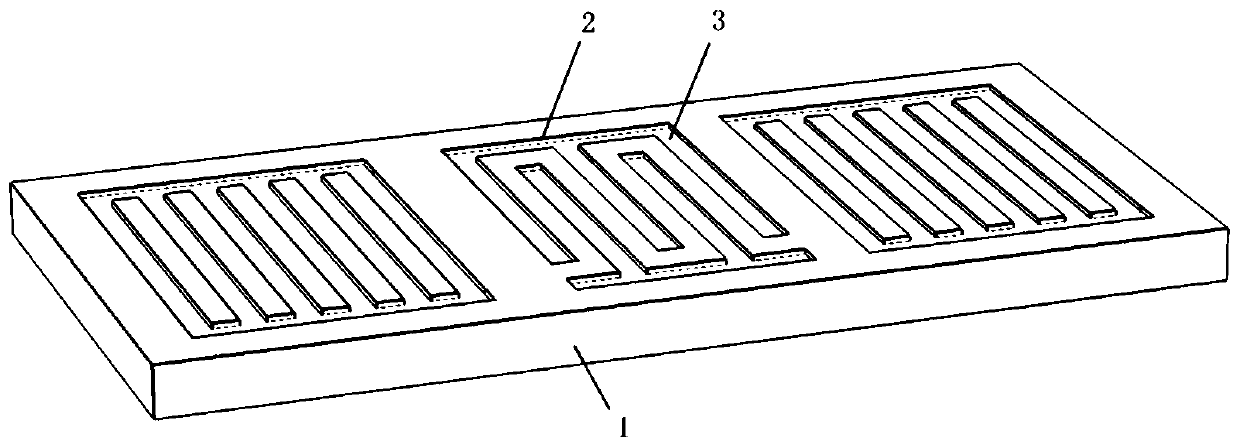

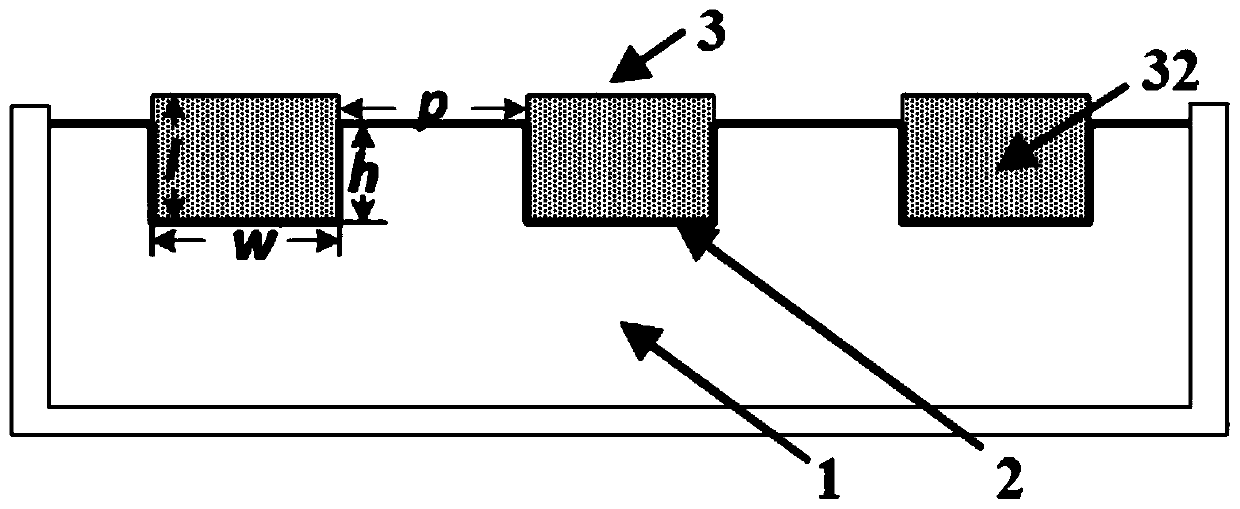

[0040] Such as image 3 As shown, a high-temperature-resistant buried electrode includes: a substrate material 1, a groove 2, and an electrode 3.

[0041] specifically:

[0042] The substrate material 1 uses piezoelectric single crystal material lanthanum gallium silicate (La 3 Ga 5 SiO 14 ), Euler angles are commonly used cuts (0°, 138.5°, 26.6°).

[0043] The grooves 2 are set at the interdigital transducer and the reflection grid to have the same depth h, the same length (the aperture lengths of the interdigital transducer and the reflection grid are respectively equal), the same width w, and the same interval p; where w =p=1.5μm, h=0.24μm.

[0044] The electrode 3 adopts a single-layer electrode, the material is metallic platinum (Pt), and the thickness l=0.3 μm.

[0045] The buried electrode disclosed in this embodiment can be used in a surface acoustic wave device operating in a high temperature environment, and can improve the degradation phenomenon of the metal thin film electr...

Embodiment 2

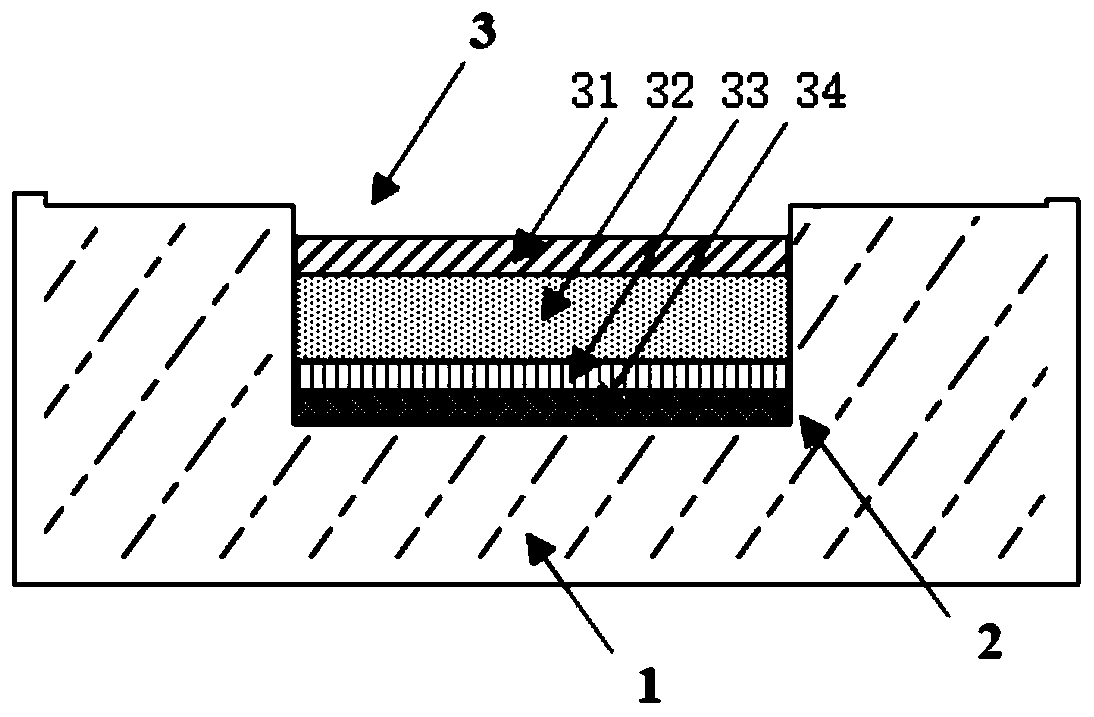

[0047] Such as Figure 4 As shown, a high-temperature-resistant embedded electrode includes: a substrate material 1, a groove 2, and an electrode 3.

[0048] specifically:

[0049] The substrate material 1 uses piezoelectric single crystal material lanthanum gallium silicate (La 3 Ga 5 SiO 14 ), Euler angles are commonly used cuts (0°, 90°, 0°).

[0050] The groove 2 is set at the interdigital transducer and the reflection grid to have the same depth h, the same length (the aperture lengths of the interdigital transducer and the reflection grid are respectively equal), the same width w, and the same spacing p; where w= p=1.5μm, h=0.42μm.

[0051] The electrode 3 adopts a multilayer electrode, from bottom to top: a buffer layer, an electrode layer, and a covering layer. Preferably, the material of the buffer layer is aluminum oxide (Al 2 O 3 ), thickness l 1 =0.06μm; the electrode layer material is metallic platinum (Pt), the thickness is l 2 =0.3μm; The material of the covering laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com