Highly-dispersed supported catalyst, and preparation method and application thereof

A supported catalyst, high dispersion technology, applied in catalyst activation/preparation, carbon monoxide reaction preparation, carbon monoxide or formate reaction preparation, etc., can solve the problems of low catalyst activity and low dispersion, and achieve high atomic utilization, The effect of high dispersion and important industrial application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Weigh 20mg (NH 4 ) 3 RhCl 6 Dissolve in 20mL of water, add 1g of activated carbon, stir for 0.5h, add 300mg of tannic acid, continue to stir for 0.5h, add 1M NaOH solution dropwise until the solution pH=11, continue to react for 2h, filter and wash until the filtrate is neutral, Dry at 70°C for 24h. After drying, the powder was placed in H at a flow rate of 50 mL / min. 2 / Ar (volume ratio 1:5) mixed atmosphere, and reduced at 160°C for 1 h to obtain a highly dispersed supported catalyst.

Embodiment 2

[0056] Weigh 20mg RhCl 3 ·3H 2 Dissolve O in 20mL of water, add 1g of activated carbon, stir for 0.5h, add 300mg of tannic acid, continue stirring for 0.5h, add 1M NaOH solution dropwise until the solution pH=10, continue to react for 2h, filter and wash until the filtrate is neutral , and dried at 70°C for 24h. After drying, the powder was placed in H at a flow rate of 50 mL / min. 2 / Ar (volume ratio 1:5) mixed atmosphere, and reduced at 160°C for 1 h to obtain a highly dispersed supported catalyst.

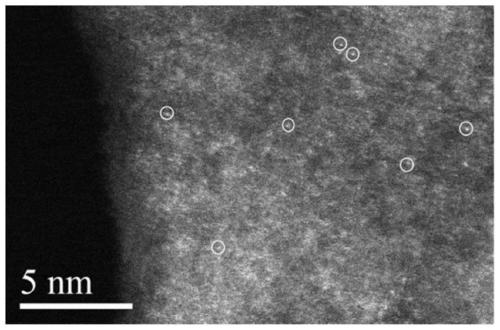

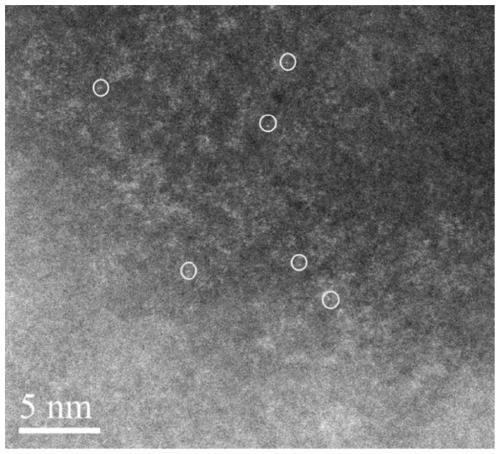

[0057] Such as figure 1 As shown, the rhodium atoms in the highly dispersed supported catalyst of this embodiment exist in the form of single atoms.

Embodiment 3

[0059] Weigh 50mg RhCl 3 ·3H 2 Dissolve O in 20mL of water, add 1g of activated carbon, stir for 0.5h, add 300mg of tannic acid, continue stirring for 0.5h, add 1M NaOH solution dropwise until the solution pH=9, continue to react for 2h, add 0.1M NaBH dropwise 4 Rh ions were reduced, filtered and washed until the filtrate was neutral, and dried at 70° C. for 24 hours to obtain a highly dispersed supported catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com