Cooperative treatment device for high-concentration nitrate waste liquid and organic waste liquid and two-phase treatment method thereof

A technology of organic waste liquid and collaborative treatment, which is applied in water/sewage treatment, chemical instruments and methods, multi-stage water/sewage treatment, etc., can solve the problems of reducing treatment cost, difficulty in nitrogen removal, high treatment cost, etc., and achieve reduced operation Power, solve the carbon source shortage, and save the effect of carbon source dosing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

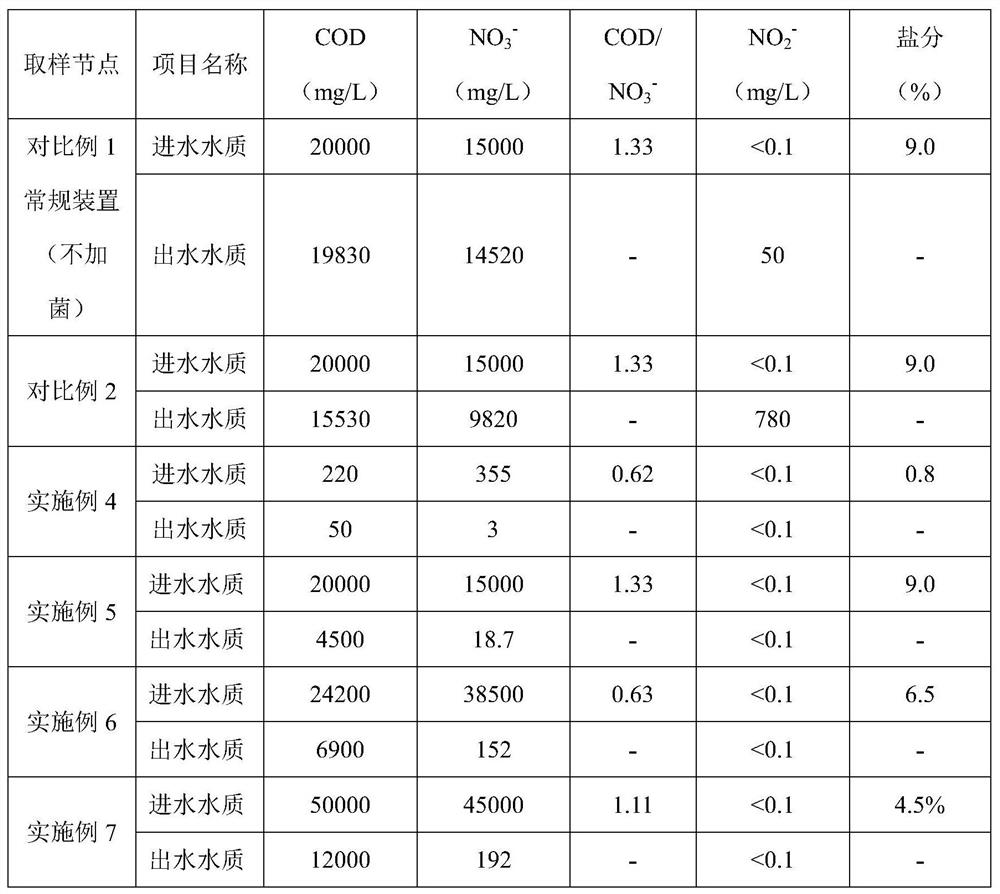

Examples

Embodiment 1

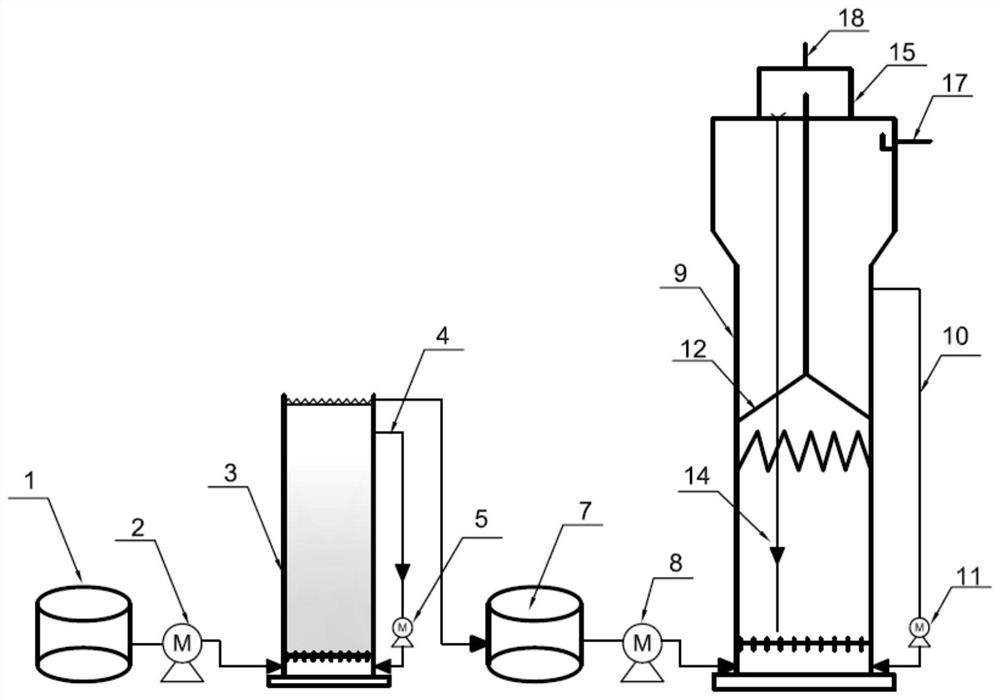

[0055] Example 1 A high-concentration nitrate waste liquid and organic waste liquid co-processing device

[0056] Refer to attached figure 1 , a device for co-processing high-concentration nitrate waste liquid and organic waste liquid, the organic waste liquid tank 1 is connected to the liquid inlet end of the anaerobic acidification reactor 3 through the first water inlet pump 2, and the anaerobic acidification reactor 3 The first return line 4 is arranged on the first return line 4, and the first return pump 5 is arranged on the first return line 4. The liquid outlet end of the anaerobic acidification reactor 3 is connected with the waste liquid mixing tank 7 through the pipeline, and the waste liquid mixing tank 7. The second water inlet pump 8 is connected to the liquid inlet end of the anaerobic denitrification reactor 9. The anaerobic denitrification reactor 9 is provided with a second return pipeline 10 and a mud-water separation bag 15 on the outside, and a third retur...

Embodiment 2

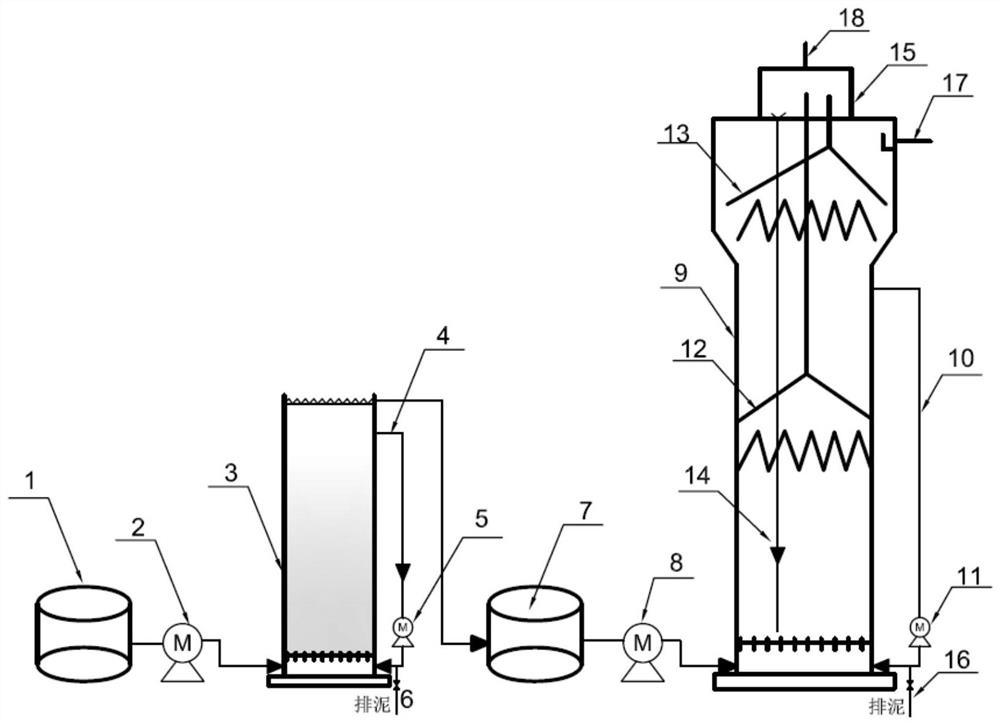

[0059] Example 2 A high-concentration nitrate waste liquid and organic waste liquid co-processing device

[0060] Refer to attached figure 2 , a device for co-processing high-concentration nitrate waste liquid and organic waste liquid, the organic waste liquid tank 1 is connected to the liquid inlet end of the anaerobic acidification reactor 3 through the first water inlet pump 2, and the anaerobic acidification reactor 3 The first return line 4 is arranged on the first return line 4, and the first return pump 5 is arranged on the first return line 4. The liquid outlet end of the anaerobic acidification reactor 3 is connected with the waste liquid mixing tank 7 through the pipeline, and the waste liquid mixing tank 7. The second water inlet pump 8 is connected to the liquid inlet end of the anaerobic denitrification reactor 9. The anaerobic denitrification reactor 9 is provided with a second return pipeline 10 on the outside, a mud-water separation bag 15 on the top of the ou...

Embodiment 3

[0069] Embodiment 3 A method for co-processing high-concentration nitrate waste liquid and organic waste liquid

[0070] Utilize the device described in embodiment 1 to carry out high-concentration nitrate waste liquid and organic waste liquid co-processing, the treatment method steps are as follows:

[0071] 1) The organic waste liquid in the organic waste liquid tank 1 enters the anaerobic acidification reactor 3 through the water inlet pump. Fully mixed and reacted with the sludge under the action of a reflux pump 5 to obtain acidification treatment waste liquid;

[0072] 2) Add the acidification treatment waste liquid and nitrate waste liquid obtained in the step 1) into the waste liquid mixing tank 7, and after the water quality is adjusted, a mixed liquid is obtained, and the mixed liquid enters the anaerobic liquid through the second water inlet pump 8 The mixed reaction is carried out in the denitrification reactor 9, the anaerobic denitrification reactor 9 contains s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com