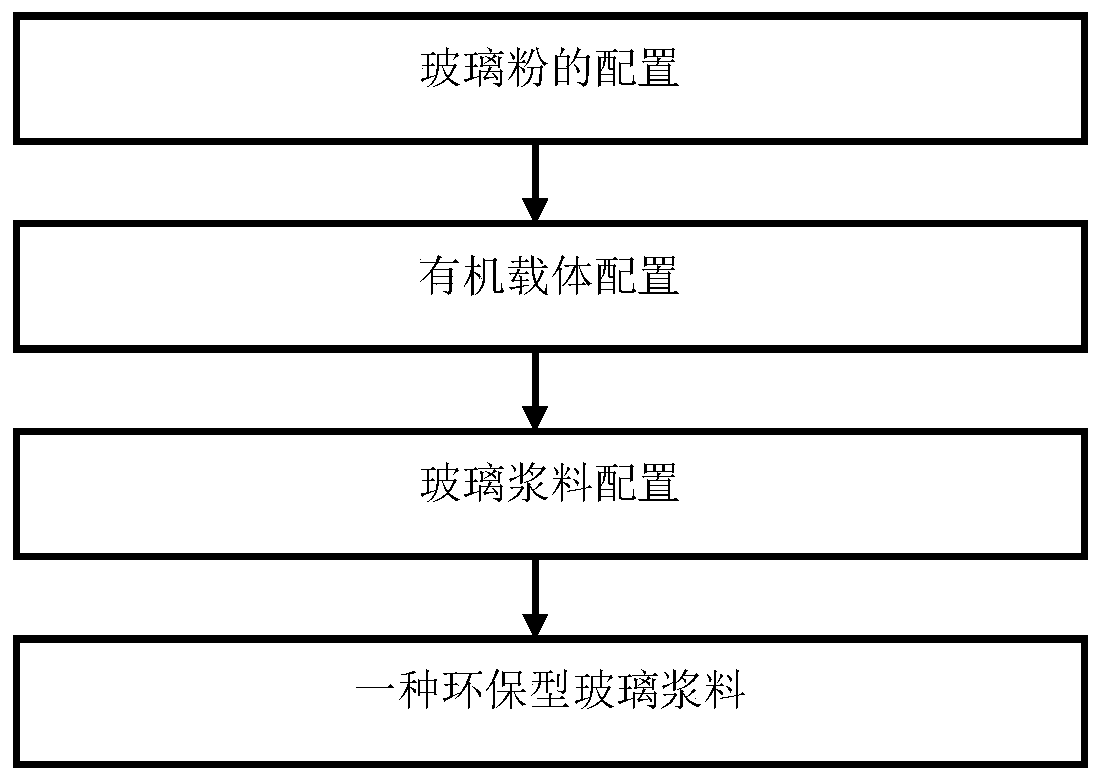

Preparation method for environmentally-friendly glass paste

A glass paste, environmentally friendly technology, used in quartz/glass/glass enamel, electrical components, circuits, etc., can solve the problems of poor bonding strength and sealing performance, easy drying of glass paste, and high printing process requirements. Good insulation and good flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0022] Step 1: Calculate by weight percentage, Bi 2 o 3 50wt.%, B 2 o 3 20wt.%, SiO 2 20wt.%, ZnO3wt.%, Al 2 o 3 3wt.%, TiO 2 4wt.% was simply physically mixed, melted at a temperature of 1200°C, kept warm for 60 minutes, and then quickly put into deionized water for water quenching and cooling to obtain cooled and solidified glass slag. Put the glass slag into a ball mill (using agate balls) for wet grinding and crushing. The mass ratio of the material to the ball is large ball (R=10mm): medium ball (R=7mm): small ball (R=3mm): glass slag =1:2:2:1, ball milling time is 24h. After ball milling, the material was dried in an oven at 60 °C for 12 h. Finally, use a 200 sieve to sieve to obtain glass powder with a particle size of 0.5 μm to 8 μm.

[0023] Step 2: the configuration of the organic carrier: by weight percentage, 10wt.% ethyl cellulose resin is added to 45wt.% butyl carbitol and 45wt.% butyl carbitol acetate solvent, in a constant temperature water tank, ...

Embodiment example 2

[0032] Step 1: Calculate by weight percentage, Bi 2 o 3 60wt.%, B 2 o 3 15wt.%, SiO 2 10wt.%, ZnO10wt.%, Al 2 o 3 3wt.%, TiO 2 2wt.% after simple physical mixing, melted at a temperature of 1300°C, kept for 40 minutes, and then quickly put into deionized water for water quenching and cooling to obtain cooled and solidified glass slag. Put the glass slag into a ball mill (using agate balls) for wet grinding and crushing, the mass ratio of the material to the ball is large ball (R=10mm): medium ball (R=7mm): small ball (R=3mm): glass slag =1:2:2:1, ball milling time is 20h. After ball milling, the material was dried in an oven at 70°C for 10 h. Finally, use a 200 sieve to sieve to obtain glass powder with a particle size of 0.5 μm to 8 μm.

[0033] Step 2: Configuration of organic solvent: Calculated by weight percentage, add 7wt.% ethyl cellulose resin to 93wt.% terpineol solvent, dissolve completely in a constant temperature water tank at a temperature of 80° C., a...

Embodiment example 3

[0042] Step 1: Calculate by weight percentage, Bi 2 o 3 70wt.%, B 2 o 3 12wt.%, SiO 2 5wt.%, ZnO10wt.%, Al 2 o 3 2wt.%, TiO 2 After simple physical mixing of 1wt.%, melt at a temperature of 1300°C, keep it warm for 30 minutes, and then quickly put it into deionized water for water quenching and cooling to obtain cooled and solidified glass slag. Put the glass slag into a ball mill (using agate balls) for wet grinding and crushing, the mass ratio of the material to the ball is large ball (R=10mm): medium ball (R=7mm): small ball (R=3mm): glass slag =1:2:2:1, ball milling time is 18h. After ball milling, the material was dried in an oven at 80 °C for 8 h. Finally, sieve with a 300 sieve to obtain glass powder with a particle size of 0.5 μm to 5 μm.

[0043] Step 2: Configuration of organic solvent: Calculated by weight percentage, add 5wt.% ethyl cellulose resin to 50wt.% terpineol solvent and 45wt.% butyl carbitol solvent, in a constant temperature water tank at a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com