Boron nitride anti-corrosion coating material and preparation method thereof

A technology of anti-corrosion coating and boron nitride, which is applied in the direction of anti-corrosion coatings, fireproof coatings, coatings, etc., can solve the problems of uneven and uneven film formation, and achieve low voc content, high hardness, flexibility and strong adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

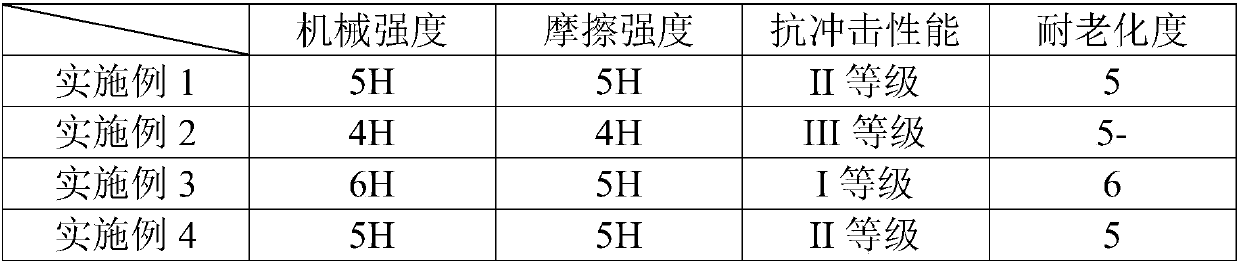

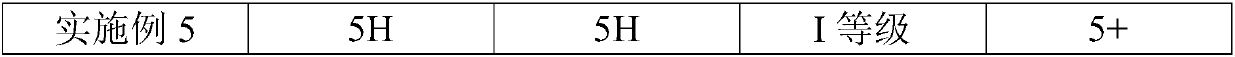

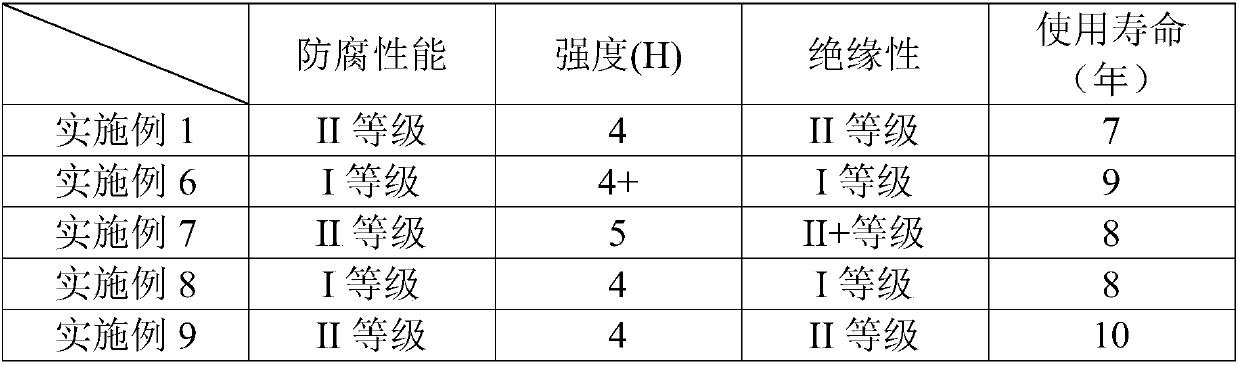

Examples

Embodiment 1

[0029] The boron nitride anti-corrosion coating material in this embodiment is composed of the following components in parts by weight: 23 parts of water-based alkyd resin, 6 parts of nano boron nitride with an average particle size of ≤120nm, 1.2 parts of polysiloxane sodium salt dispersant, fluorine fluid 1.5 parts of leveling agent and 75 parts of solvent, wherein the solvent is composed of m-xylene, cyclohexanone and ethylene glycol ether in a volume ratio of 2:3:1.

[0030] The preparation method is as follows: first use a ball mill to grind the nano-boron nitride evenly, then mix it with a solvent to make a boron nitride slurry, and then add a dispersant to the boron nitride slurry to make a boron nitride filler dispersion , and finally mix the boron nitride filler dispersion prepared above with water-based alkyd resin, stabilize and uniformly disperse, and make a boron nitride anti-corrosion coating material.

Embodiment 2

[0032] The boron nitride anti-corrosion coating material of this embodiment is composed of the following components in parts by weight: 23 parts of water-based alkyd resin, 5 parts of nano boron nitride with an average particle size of ≤120nm, 1.2 parts of polysiloxane sodium salt dispersant, fluorine fluid 1.5 parts of leveling agent and 75 parts of solvent, wherein the solvent is composed of m-xylene, cyclohexanone and ethylene glycol ether in a volume ratio of 2:3:1.

[0033] The preparation method is the same as in Example 1.

Embodiment 3

[0035] The boron nitride anti-corrosion coating material in this embodiment is composed of the following components in parts by weight: 23 parts of water-based alkyd resin, 7 parts of nano boron nitride with an average particle size of ≤120nm, 1.2 parts of polysiloxane sodium salt dispersant, fluorine fluid 1.5 parts of leveling agent and 75 parts of solvent, wherein the solvent is composed of m-xylene, cyclohexanone and ethylene glycol ether in a volume ratio of 2:3:1.

[0036] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com