Soda lime or calcium lime granulation process system

A process system and calcium lime technology, applied in the field of soda lime or calcium lime granulation process system, can solve the problems of poor continuity and low production efficiency of soda lime production process, and achieve increased continuity, improved production efficiency, and improved continuity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following is further described in detail through specific implementation methods:

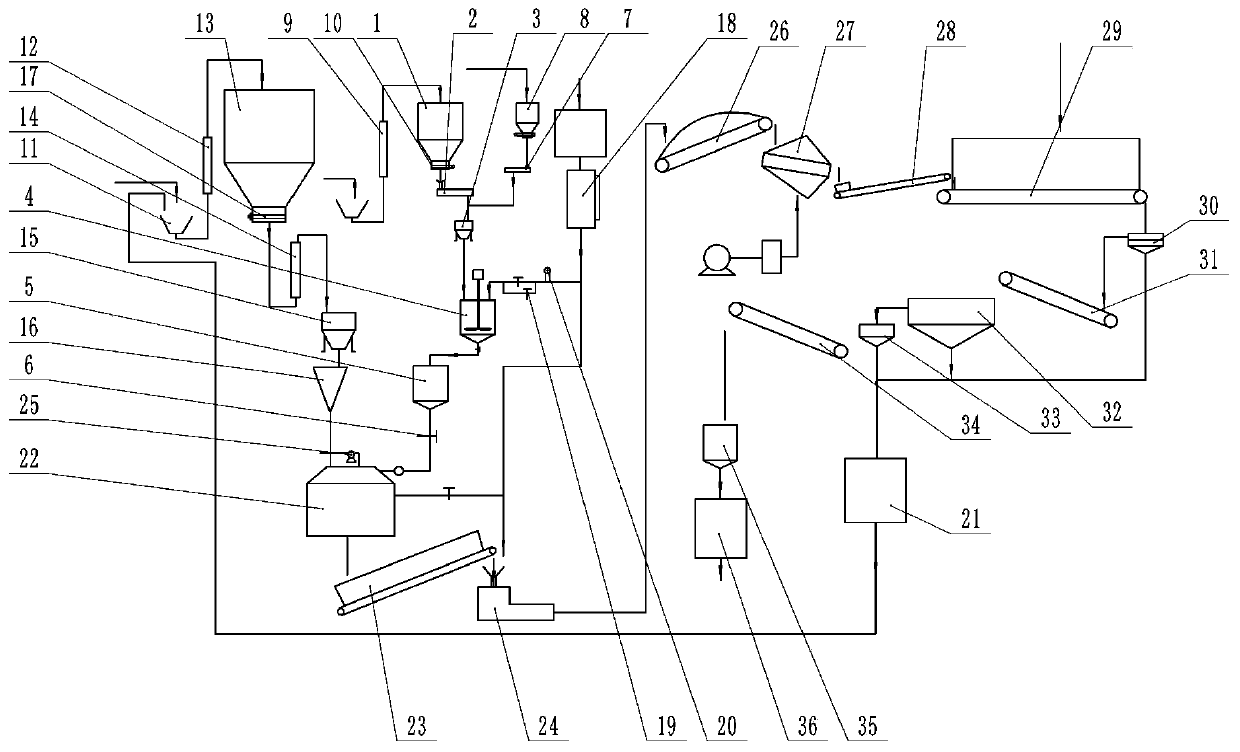

[0016] The reference signs in the accompanying drawings of the description include: sodium hydroxide silo 1, first feeder 2, first scale body 3, mixing tank 4, buffer tank 5, second solenoid valve 6, second feeder 7 , Dadan yellow silo 8, the first pipe chain conveyor 9, the first flap valve 10, receiving hopper 11, the second pipe chain conveyor 12, calcium hydroxide silo 13, the third pipe chain conveyor 14, the first Second scale body 15, buffer bucket 16, second flap valve 17, bucket 18, manual valve 19, flow meter 20, combustion furnace 21, mixing granulator 22, material storage conveyor belt 23, granulator 24, vacuum pump 25, Chain plate conveyor 26, vibrating dryer 27, distributor 28, belt dryer 29, powder removal and screening machine 30, first conveyor belt 31, hydration equipment 32, inspection and screening machine 33, second conveyor belt 34, buffer bin 35 36. Automatic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com