Method for preparing casein stabilized Pickering high internal phase emulsion

A technology of high internal phase emulsion and casein is applied in the field of emulsion preparation and achieves the effects of wide application prospect, simple equipment and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] S1. Preparation of casein solution: Accurately weigh 0.15 g of casein and add 5 mL of water, stir continuously at room temperature for 8 hours, adjust the pH to 11 with 0.5 g / mL potassium hydroxide until the casein is completely dissolved, and stir at room temperature for 1 hour to obtain casein solution;

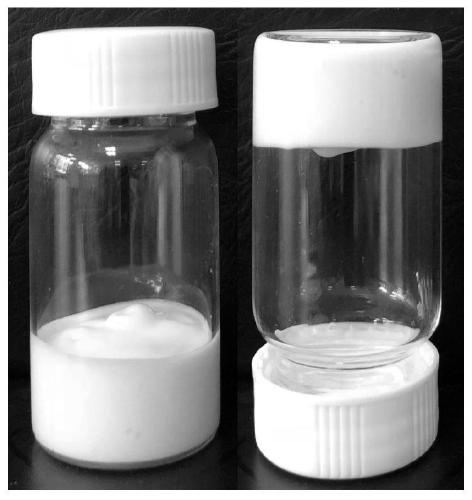

[0050] S2. Preparation of high internal phase emulsion: Add 20 mL of soybean oil to the casein solution described in step S1, and use IKA T25 high-speed homogenizer to shear at 12000 rpm for 3 minutes to prepare Pickering high internal phase emulsion. Lotion looks like figure 1 As shown, in the 20mL sample bottle, it will not flow upside down. The emulsion was stored at 4°C for 60 days, and no phase separation visible to the naked eye occurred.

[0051] Take a certain amount of emulsion for viscoelasticity test, using a flat plate with a diameter of 40mm, the test temperature is 25°C, the height is 1000μm, the strain is 0.5%, and the shear frequency range is 0.1Hz ...

Embodiment 2

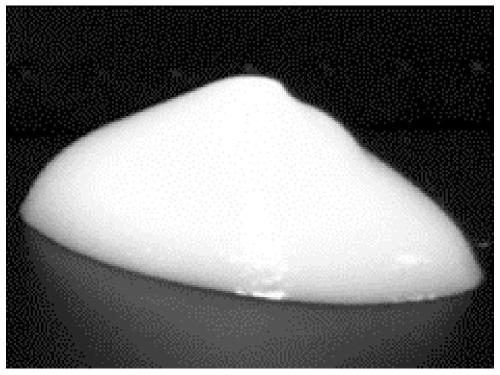

[0053] Accurately weigh 0.15g of casein, add 5mL of water and stir continuously at room temperature for 12h, adjust the pH to 11 with 0.5g / mL potassium hydroxide until the casein is completely dissolved, stir at room temperature for 1 hour, then adjust the pH to 12mol / L hydrochloric acid 10. Obtain a casein solution; add 20 mL of salad oil to the casein solution, and use an IKA T25 high-speed homogenizer to shear at a high speed of 10,000 rpm for 3 minutes to prepare a Pickering high internal phase emulsion. Lotion looks like figure 2 As shown, in the 20mL sample bottle, it will not flow upside down. Such as image 3 As shown, the emulsion has a certain plasticity. The emulsion was stored at 4°C for 60 days, and no phase separation visible to the naked eye occurred.

[0054] Take a certain amount of emulsion for viscoelasticity test, using a flat plate with a diameter of 40mm, the test temperature is 25°C, the height is 1000μm, the strain is 0.5%, and the shear frequency r...

Embodiment 3

[0057] Accurately weigh 0.15g of casein, add 5mL of water and stir continuously at room temperature for 12h, adjust the pH to 11 with 0.5g / mL potassium hydroxide until the casein is completely dissolved, stir at room temperature for 1 hour, then adjust the pH to 12mol / L hydrochloric acid 9. Obtain a casein solution; add 20 mL of blended oil to the casein solution, and use an IKAT25 high-speed homogenizer to shear at a high speed of 9000 rpm for 3 minutes to prepare a Pickering high internal phase emulsion. Lotion looks like Figure 4 As shown, in the 20mL sample bottle, it will not flow upside down. The emulsion was stored at 4°C for 60 days, and no phase separation visible to the naked eye occurred.

[0058] Take a certain amount of emulsion for viscoelasticity test, using a flat plate with a diameter of 40mm, the test temperature is 25°C, the height is 1000μm, the strain is 0.5%, and the shear frequency range is 0.1Hz to 10Hz (all implementation cases are under this conditi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com