Autoclaved aerated concrete slab and preparation method thereof

A technology of autoclaved air filling and concrete slabs, which is applied in the direction of manufacturing tools, building components, ceramic molding machines, etc. It can solve the problems of inconvenient setting of pipeline grooves, and achieve the effects of avoiding structural strength damage, improving production efficiency, and convenient positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with accompanying drawing:

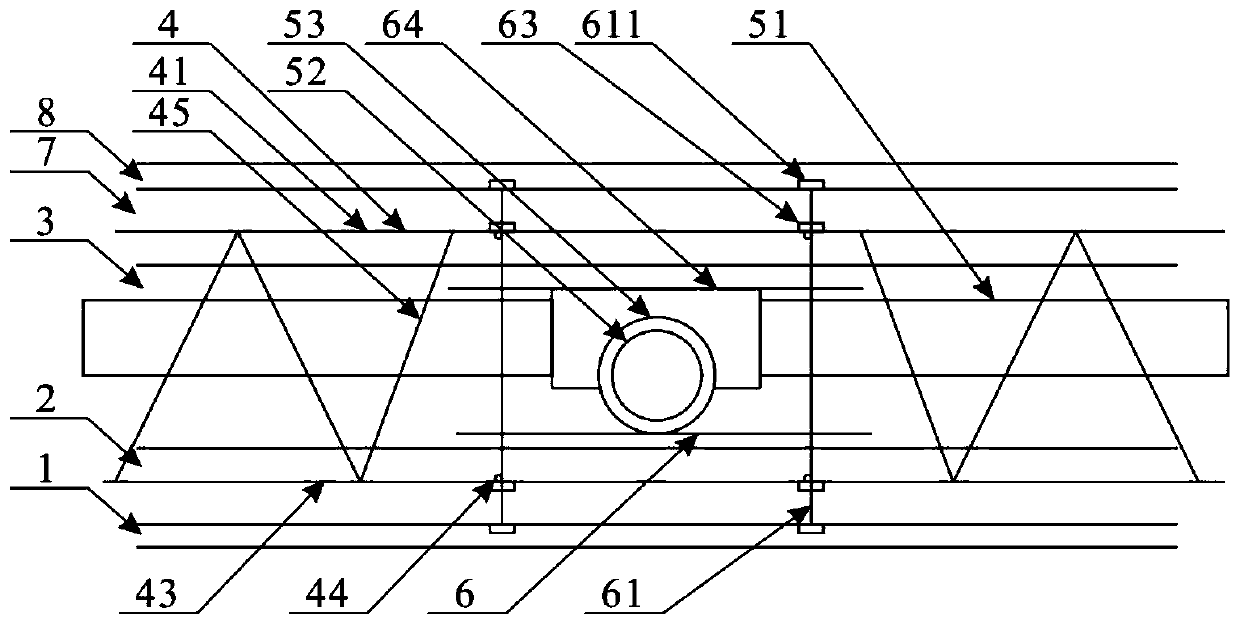

[0039] Such as figure 1 As shown, it is a schematic structural diagram of an autoclaved aerated concrete slab.

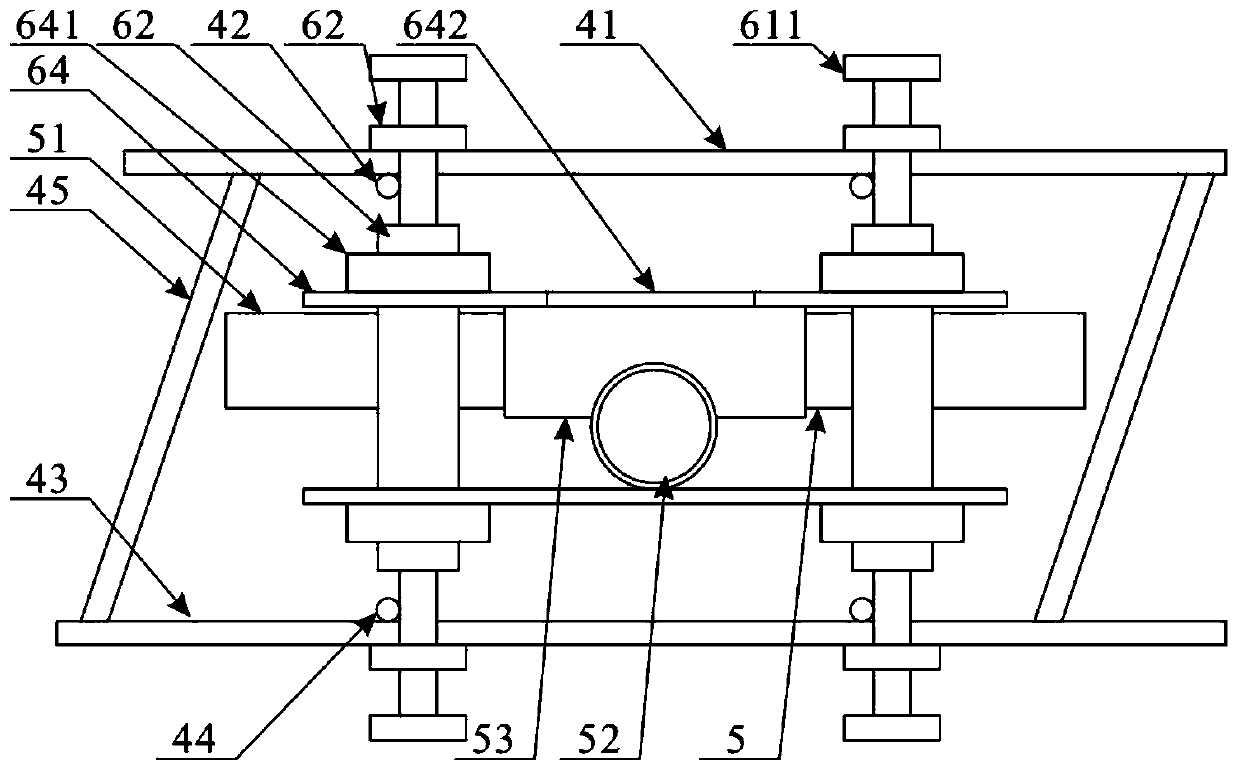

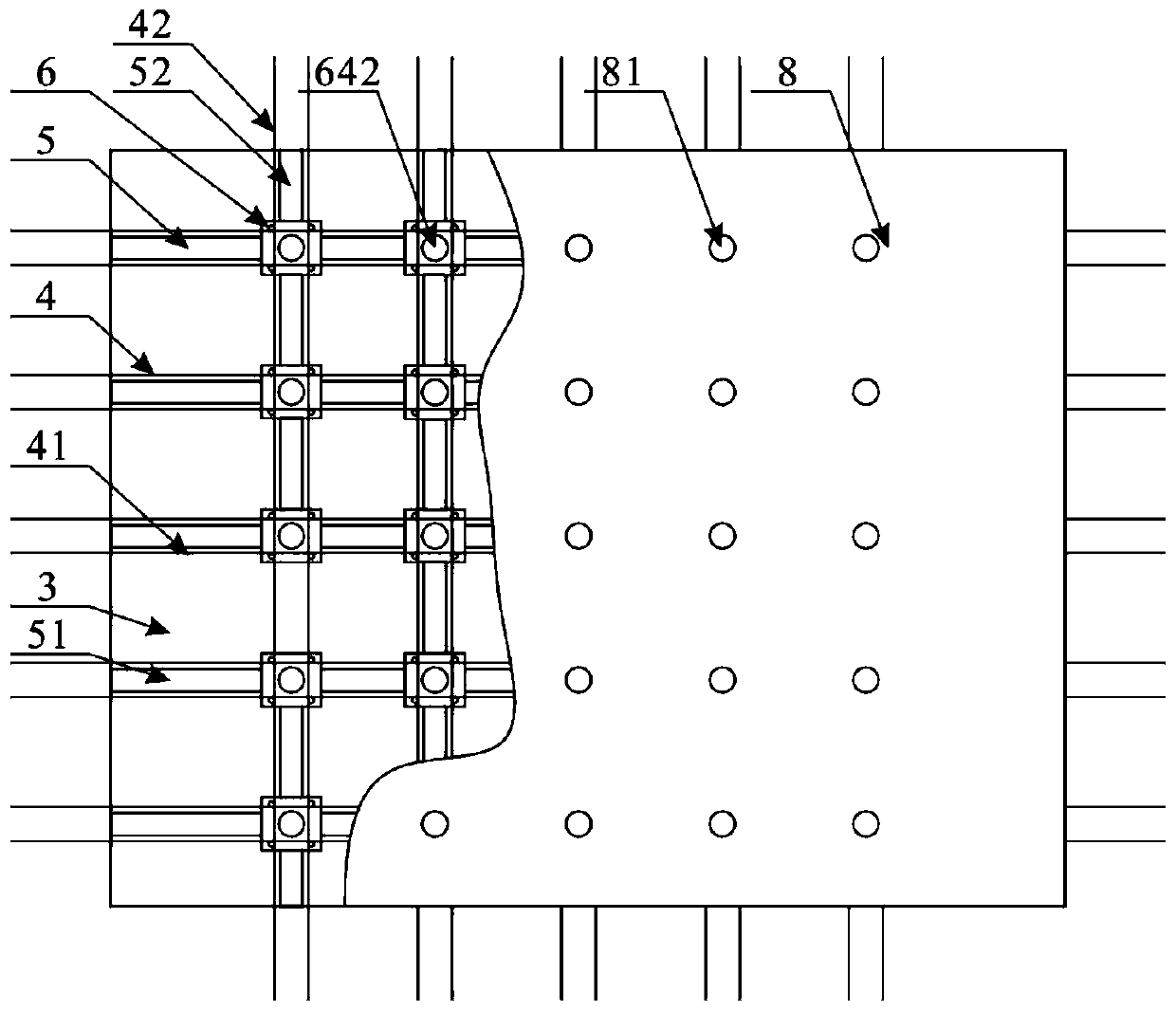

[0040] An autoclaved aerated concrete slab of the present invention comprises a substrate layer 1, a fiber layer 2, an autoclaved aerated concrete core layer 3, an insulating layer 7 and an outer finish layer 8 arranged in sequence, such as image 3 As shown, several pre-embedded pipes 5 are arranged in the autoclaved aerated concrete core layer 3 .

[0041] By setting the pre-embedded pipe 5, a pre-embedded pipe groove is formed in the plate body; when the green body at the position of the pre-embedded pipe 5 reaches the target hardness during the preparation process, the pre-embedded pipe 5 can be pulled out, and the pre-embedded pipe 5 can be placed The position forms a pre-buried pipe groove.

[0042] By arranging a plurality of pre-embedded pipes 5, wirin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com