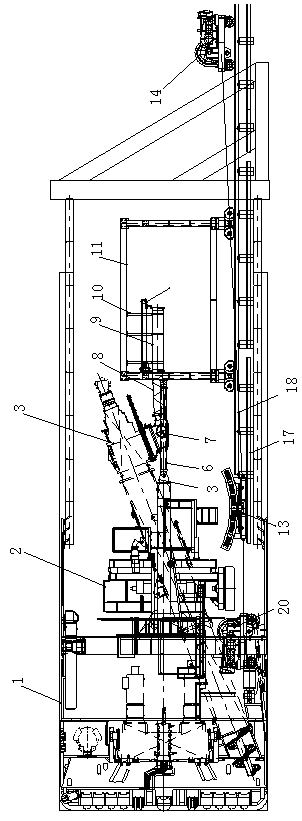

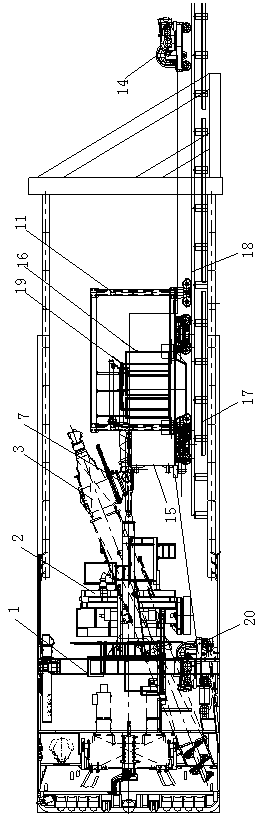

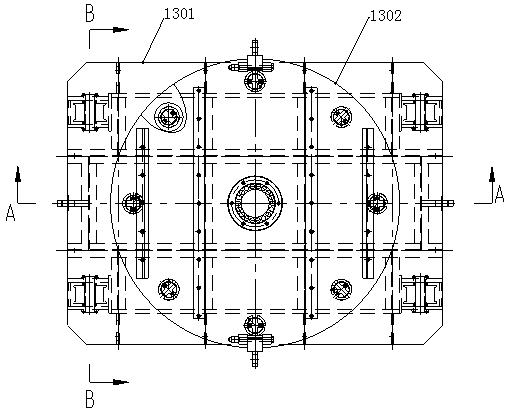

Split starting supporting device applied to tiny starting well and starting construction method

A split origination and origination shaft technology, which is applied in shaft equipment, wellbore lining, earthwork drilling and production, etc., can solve the problems of difficulty in construction of origination devices and low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

[0040] Embodiment 3: A starting construction method applied to a split starting supporting device of a very small starting shaft, including muck transportation and segment transportation, wherein the muck transportation includes the following steps:

[0041] S1: Connect the front and rear ends of the slag bucket truck to the second hoist and the first hoist respectively;

[0042] S2: The second winch drives the slag bucket truck to the bottom of the hard pipe, and the slag outlet of the hard pipe is just aligned with the slag bucket truck to ensure that the slag can smoothly fall into the slag bucket truck, and then the slag passes through the screw conveyor and the slag discharge box The body, hose and hard pipe fall into the slag bucket truck;

[0043] S3: When the slag bucket truck is full of slag, the first hoist drives the slag bucket truck and exits the tunnel to complete a slag transportation;

[0044] S4: Repeat steps S2~S3 until all the transportation of the muck is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com