Power shearing mechanism for hydraulic pump

A hydraulic pump and power technology, which is applied in the field of hydraulic plunger pumps, can solve the problems of low universality of hydraulic pumps, and achieve the effects of universality, application market improvement, and performance optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

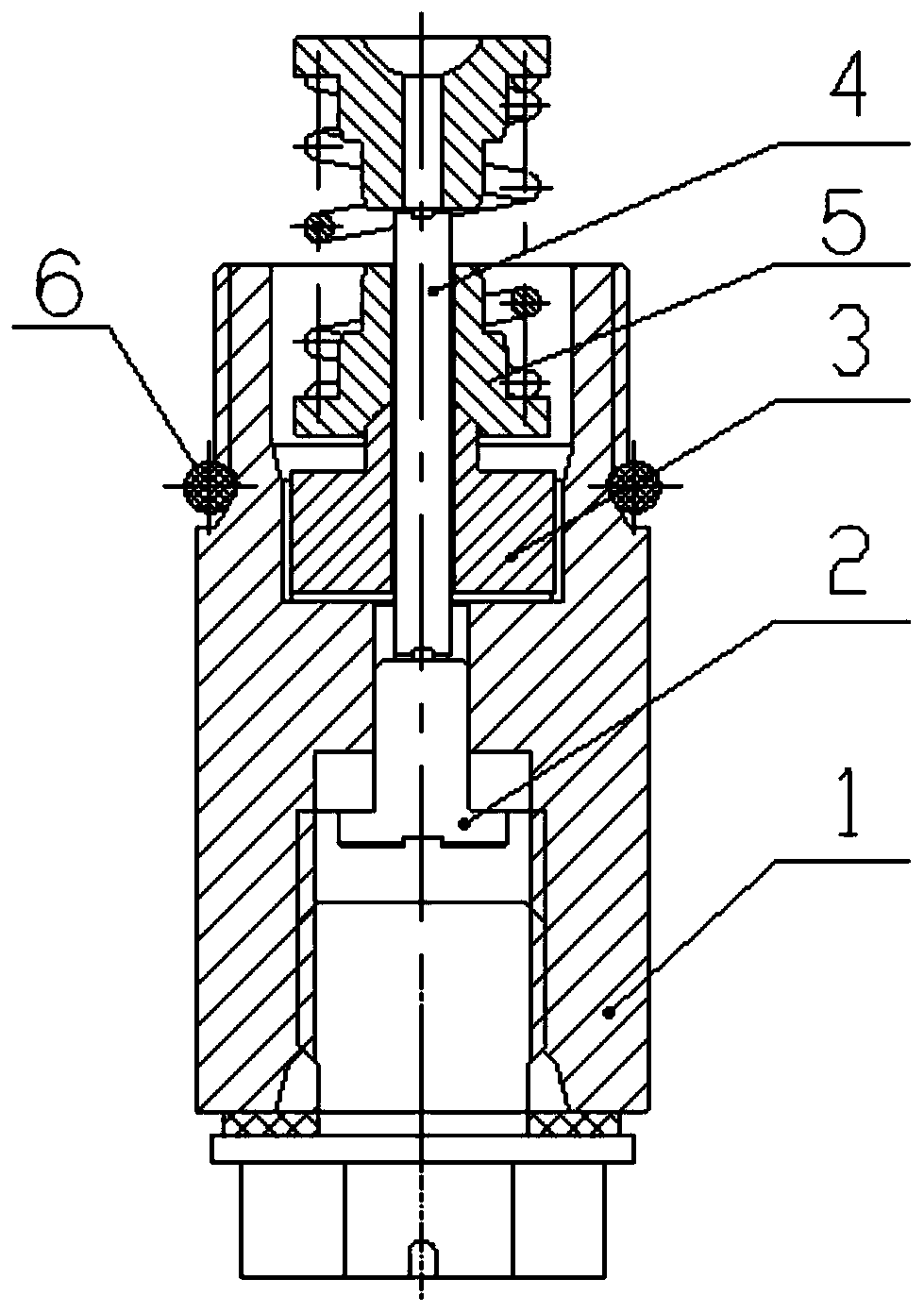

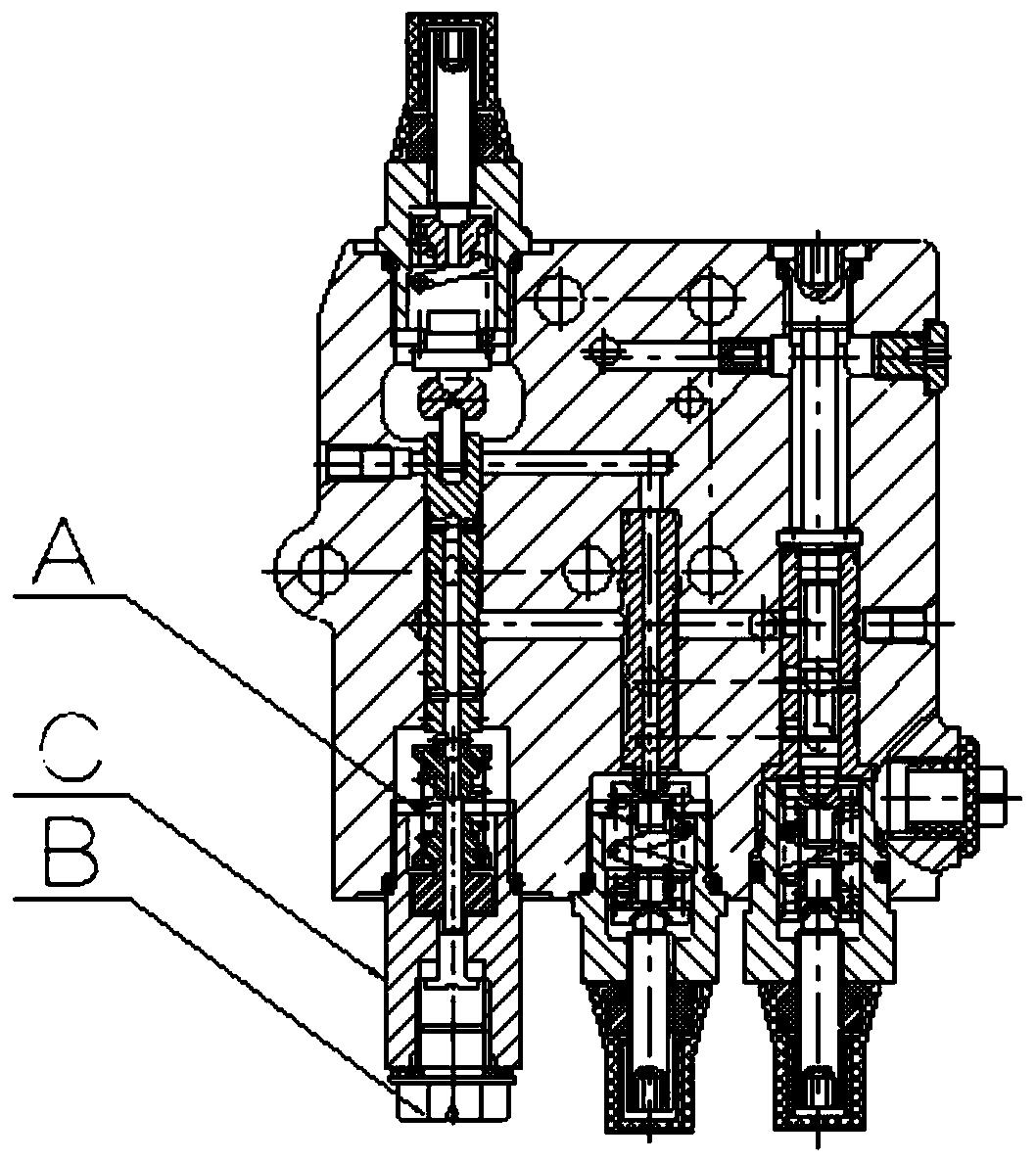

[0018] Such as figure 1 As shown, a hydraulic pump power shearing mechanism provided by the present invention includes:

[0019] Nut 1, used to connect the electric proportional control valve body in the power control unit A and the pilot oil port B;

[0020] Top seat 2, used to control the flow in pilot oil port B;

[0021] The ejector rod 4 is used to control the top seat 2;

[0022] The spacer 3 is used to limit the ejector rod 4 in the nut 1, and the nut 1 is provided with a position-limiting structure matched with the spacer 3;

[0023] The spring seat 5 is used to reset the push rod 4.

[0024] The end of the nut 1 connected to the pilot oil port B is provided with a depression, and the top seat 2 is set in the depression; one end of the top seat 2 is set in the pilot oil port B, and the other end is connected with the ejector rod 4, and the ejector rod 4 passes through in turn. Through the spacer 3 and the spring seat 5, it is exposed from the end where the nut 1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com