Lithium ion battery negative electrode material, and preparation method and application thereof

A lithium-ion battery and negative electrode material technology, applied in the field of materials, can solve the problems of easy structure damage, large volume change, and poor cycle stability, and achieve excellent rate performance, good cycle performance, and good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The present invention also provides a preparation method of the lithium ion battery negative electrode material according to the above technical solution, which includes the following steps:

[0031] (1) Put Ti 3 AlC 2 , LiF and hydrochloric acid are mixed and heated, and the solid is collected by centrifugation to obtain layered Ti 3 C 2 material;

[0032] (2) The layered Ti obtained in the step (1) 3 C 2 The material is ultrasonically treated in water and centrifuged, the liquid is collected and then dried to obtain stripped Ti 3 C 2 material;

[0033] (3) The stripped Ti obtained in the step (2) 3 C 2 The materials, nickel sulfate, urotropine, and water are mixed and subjected to hydrothermal compounding to obtain negative electrode materials for lithium-ion batteries.

[0034] In the present invention, all raw materials are commercially available products.

[0035] The present invention will Ti 3 AlC 2 , LiF and hydrochloric acid are mixed and heated, and the solid is collect...

Embodiment 1

[0046] 1.5g Ti 3 AlC 2 Put it into a mixed solution of 2gLiF and 20mL 10mol / L hydrochloric acid and heat and stir at 30°C for 48h. The corroded sample was washed once with 1mol / L hydrochloric acid, and then washed with deionized water to pH 6 by centrifugation, added with 1000mL deionized water, sonicated for 3h under argon protection, centrifuged at 2000rpm for 1h, and the upper layer Freeze-drying to obtain stripped Ti 3 C 2 ; Take 0.1676g of stripped Ti 3 C 2 , Add 70mL of deionized water, add 0.1314g of nickel sulfate hexahydrate and 0.2g of uterolol after 30min of ultrasound, stir for 30min, transfer to a 100mL reactor, keep it at 90℃ for 10h, centrifuge with deionized water for three times Freeze drying, you can get Ni(OH) 2 / d-Ti 3 C 2 Composite materials.

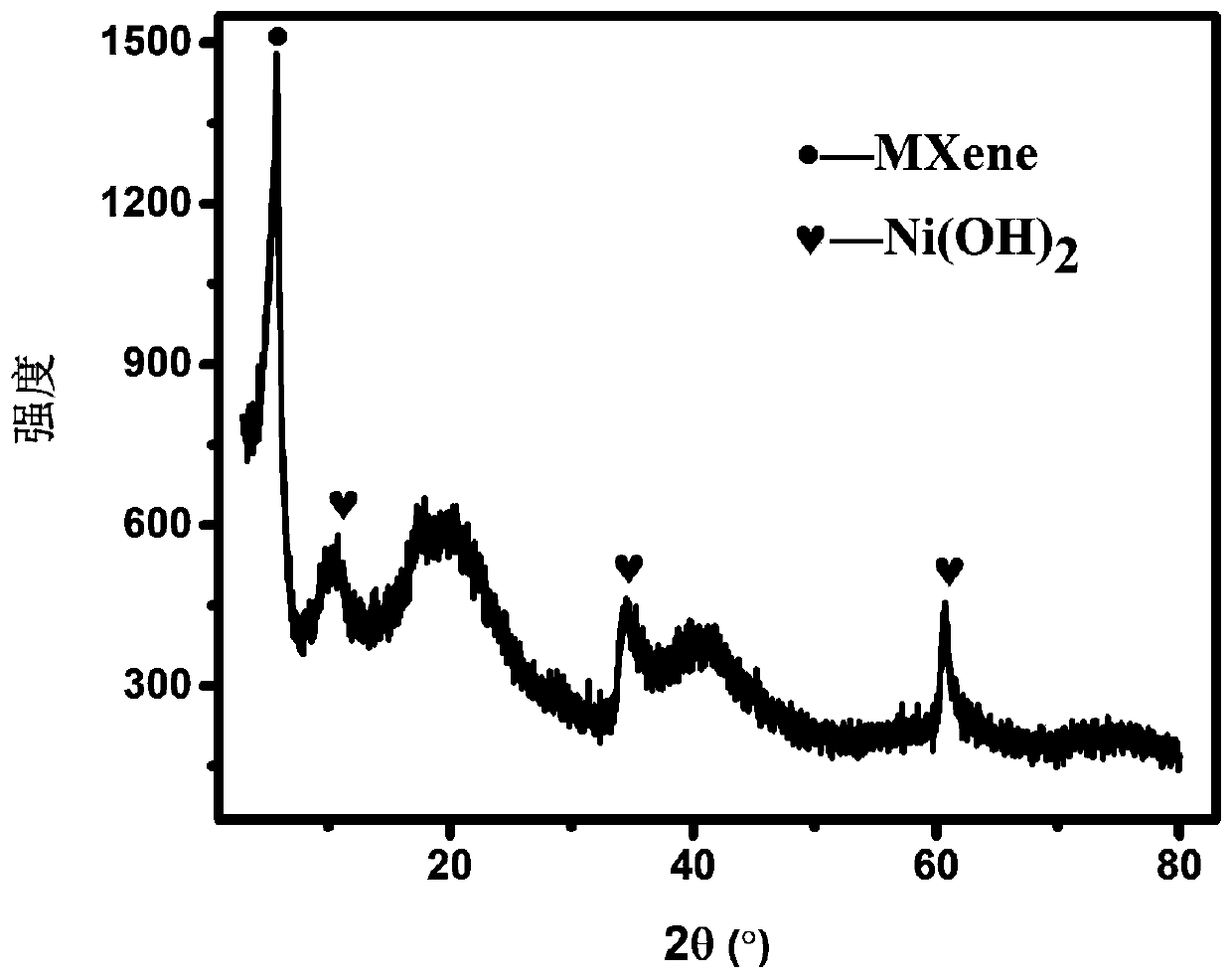

[0047] figure 1 Ni(OH) 2 / d-Ti 3 C 2 The XRD pattern of the composite material, it can be seen from the figure that there is obvious α-phase Ni(OH) 2 And Ti 3 C 2 Peaks, proving that the material is indeed made of Ni(O...

Embodiment 2

[0051] 1.5g Ti 3 AlC 2 Put it into a mixed solution of 2g LiF and 20mL 10mol / L hydrochloric acid and heat and stir at 30°C for 48h. The corroded sample was washed once with 1mol / L hydrochloric acid, and then washed with deionized water to pH 6 by centrifugation, added with 1000mL deionized water, sonicated for 3h under argon protection, centrifuged at 2000rpm for 1h, and the upper layer Freeze-drying to obtain stripped Ti 3 C 2 ; Take 0.1676g of stripped Ti 3 C 2 , Add 70mL of deionized water, add 0.3942g of nickel sulfate hexahydrate and 0.2g of uterolol after 30min of ultrasound, stir for 30min, transfer to a 100mL reactor, keep it at 100℃ for 8h, centrifuge with deionized water for three times Freeze drying, you can get Ni(OH) 2 / d-Ti 3 C 2 Composite materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge specific capacity | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com