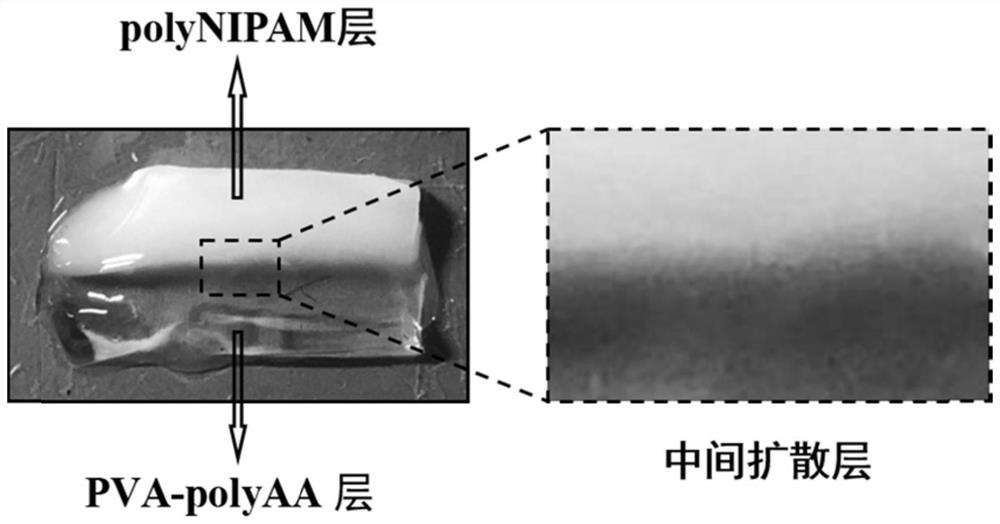

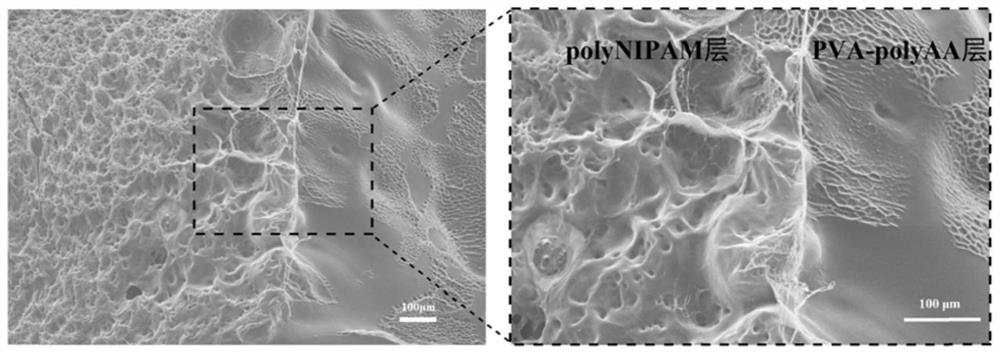

A method for preparing hydrogel with asymmetric structure in one step by using viscosity difference and its product and application

An asymmetric and structured water technology, applied in the field of polymer hydrogel, can solve the problems of difficulty in accurately controlling particle dispersion, high selection requirements, and low universality, and achieve high application value and practical operability. The preparation method is simple and the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Take 0.05g polyvinyl alcohol (PVA-1799) and disperse it in 0.5g water, and dissolve it fully in a water bath at 80°C; weigh 0.4g acrylic acid (AA) and dissolve it in 1.5g water, add 2mg potassium persulfate (KPS) and 3mg N,N-methylenebisacrylamide (MBAA) was sonicated until it was dissolved, put it in an ice-water bath, and after standing for 15 minutes, 15 μL N,N,N',N'-tetramethylethylenediamine (TEMED) was added, and then Inject the above polyvinyl alcohol solution to obtain the reaction solution a, mix the reaction solution a evenly, blow nitrogen gas-vacuumize to remove oxygen, and inject it into a mold after cooling. The mold is composed of two layers of quartz glass and a PTFE separator with a thickness of 2mm.

[0038]Then take 0.113g of N-isopropylacrylamide (NIPAM) and dissolve it in 0.5g of water, then add 1.08mg of potassium persulfate (KPS) and 0.375mg of N,N-methylenebisacrylamide (MBAA) and sonicate until dissolved. Add 20 μL of N,N,N',N'-tetramethylethyle...

Embodiment 2

[0041] Take 0.05g of polyvinyl alcohol (PVA-1799) and disperse it in 0.5g of water, and dissolve it fully in a water bath at 80°C; take 0.113g of N-isopropylacrylamide (NIPAM) and dissolve it in 0.5g of water, then add 1.08mg of potassium persulfate (KPS) and 0.375 mg N,N-methylenebisacrylamide (MBAA) were sonicated until dissolved, 20 μL N,N,N',N'-tetramethylethylenediamine (TEMED) was added, and then injected into the above polyethylene The reaction solution a was obtained from the alcohol solution, mixed evenly, passed through nitrogen, vacuumed to remove oxygen, cooled and poured into a mold. The mold was composed of two layers of quartz glass and a PTFE separator with a thickness of 2 mm.

[0042] Then weigh 0.4g of acrylic acid (AA) and dissolve it in 1.5g of water, add 2mg of potassium persulfate (KPS) and 3mg of N,N-methylene bisacrylamide (MBAA) to ultrasonic until dissolved, put it in an ice-water bath, and After standing for 15 minutes, add 15 μL of N,N,N',N'-tetram...

Embodiment 3

[0044] Take 0.05g of polyvinyl alcohol (PVA-1799) and disperse it in 0.5g of water, and dissolve it fully in a water bath at 80°C; take 0.113g of N-isopropylacrylamide (NIPAM) and dissolve it in 0.5g of water, and then add 1.3mg of potassium persulfate (KPS) and 0.375 mg N,N-methylenebisacrylamide (MBAA) were sonicated until dissolved, 20 μL N,N,N',N'-tetramethylethylenediamine (TEMED) was added, and then injected into the above polyethylene The reaction solution a was obtained from the alcohol solution, mixed evenly, passed through nitrogen, vacuumed to remove oxygen, cooled and poured into a mold. The mold was composed of two layers of quartz glass and a PTFE separator with a thickness of 2mm.

[0045] Then weigh 0.4g of acrylamide (AAm) and dissolve it in 1g of water, add 2mg of potassium persulfate (KPS) and 3mg of N,N-methylenebisacrylamide (MBAA) to ultrasonic until dissolved, put it in an ice-water bath, and After standing for 15 minutes, add 15 μL of N,N,N',N'-tetramet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com