Transgranular grain boundary distribution micro-nano complex particle reinforced aluminum base composite material and preparation method thereof

A particle-reinforced aluminum and composite material technology, which is applied in the field of advanced metal matrix composite material preparation, can solve the problems of reducing material plasticity and toughness, potential safety hazards, particle segregation, etc., and achieves accelerated reaction process, reduced production cost, and uniform organization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

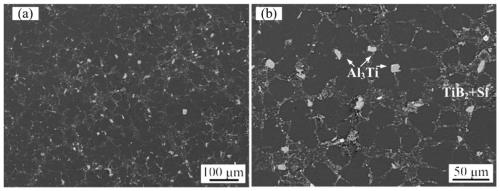

Examples

Embodiment 1

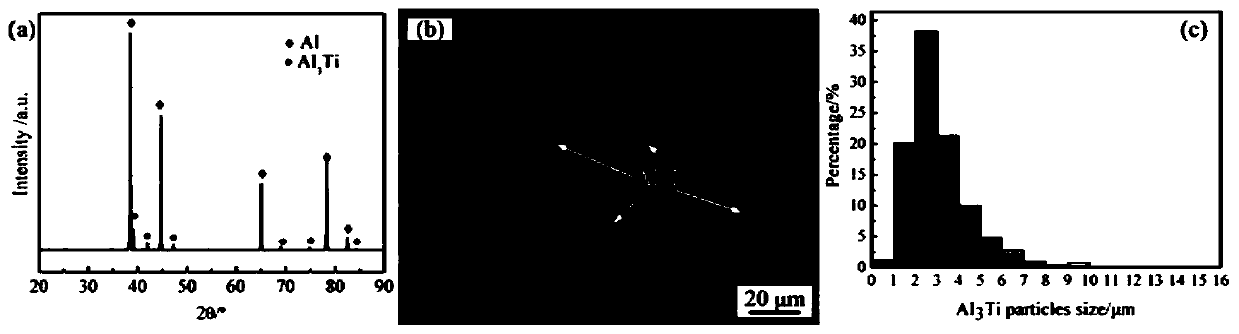

[0036] Step 1: Put K 2 TiF 6 The powder is added to the pure aluminum melt at a temperature of 750°C, and at the same time, the Nb-Zr alloy ultrasonic amplitude rod is immersed in the melt, and the ultrasonic treatment is performed for 10 minutes, with an ultrasonic power of 1.2kW, to remove liquid molten salt impurities on the surface of the melt, and after pouring, it is obtained Al-Al 3 Ti master alloy, the resulting Al-Al 3 Al in Ti master alloy 3 The mass fraction of Ti particles is 10%.

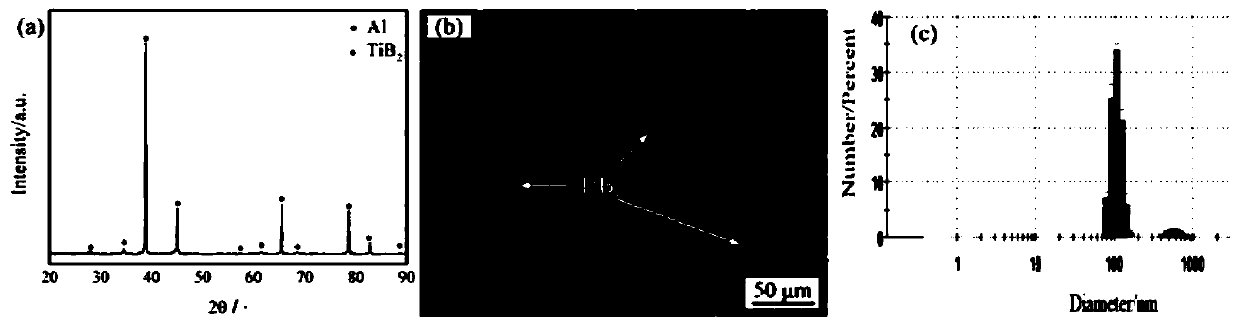

[0037] Step 2: Put K 2 TiF 6 、KBF 4 The powders were mixed according to the molar ratio of 1:2, and after being fully mixed, they were then added to the pure aluminum melt at a temperature of 800 °C. At the same time, the Nb-Zr alloy ultrasonic amplitude rod was immersed in the melt, and the ultrasonic treatment was performed for 10 minutes. The ultrasonic power was 1.2kW, remove liquid molten salt impurities on the surface of the melt, and obtain Al-TiB after casting 2 master a...

Embodiment 2

[0043] Step 1: Put K 2 TiF 6 The powder is added to the pure aluminum melt at a temperature of 800°C, and at the same time, the Nb-Zr alloy ultrasonic amplitude rod is immersed in the melt, ultrasonically treated for 5 minutes, and the ultrasonic power is 1.5kW, to remove liquid molten salt impurities on the surface of the melt, and after pouring, it is obtained Al-Al 3 Ti master alloy, the resulting Al-Al 3 Al in Ti master alloy 3 The mass fraction of Ti particles is 15%.

[0044] Step 2: Put K 2 TiF 6 、KBF 4 The powders were mixed according to the molar ratio of 1:2. After being fully mixed, they were then added to the pure aluminum melt at a temperature of 850 ° C. At the same time, the Nb-Zr alloy ultrasonic amplitude rod was immersed in the melt, and the ultrasonic treatment was performed for 5 minutes. The ultrasonic power was 1.2kW, remove liquid molten salt impurities on the surface of the melt, and obtain Al-TiB after casting 2 master alloy, the resulting Al-T...

Embodiment 3

[0047] Step 1: Put K 2 TiF 6 The powder is added to the pure aluminum melt at a temperature of 700 ° C, and at the same time, the Nb-Zr alloy ultrasonic amplitude rod is immersed in the melt, and the ultrasonic treatment is performed for 10 minutes with an ultrasonic power of 1.0kW to remove liquid molten salt impurities on the surface of the melt. Al-Al 3 Ti master alloy, the resulting Al-Al 3 Al in Ti master alloy 3 The mass fraction of Ti particles is 8%.

[0048] Step 2: Put K 2 TiF 6 、KBF 4 The powders were mixed according to the molar ratio of 1:2. After being fully mixed, they were then added to the pure aluminum melt at a temperature of 750 °C. At the same time, the Nb-Zr alloy ultrasonic amplitude rod was immersed in the melt, and the ultrasonic treatment was performed for 8 minutes. The ultrasonic power was 1.5kW, remove liquid molten salt impurities on the surface of the melt, and obtain Al-TiB after casting 2 master alloy, the resulting Al-TiB 2 TiB in mas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com