Plated steel

A steel and coating technology, applied in the direction of electrophoretic coating, superimposed layer coating, hot-dip coating process, etc., can solve the problems of corrosion resistance degradation, joint strength reduction, etc., to improve corrosion resistance and inhibit the formation of pores Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

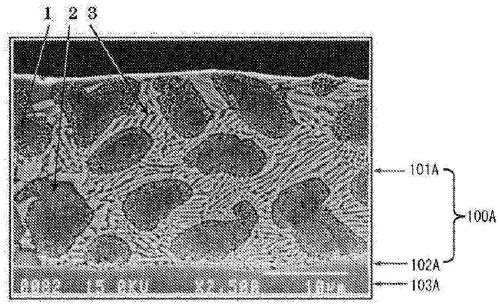

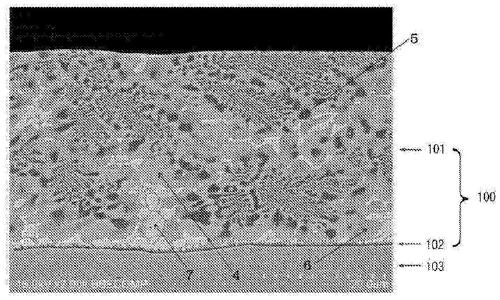

Image

Examples

Embodiment A

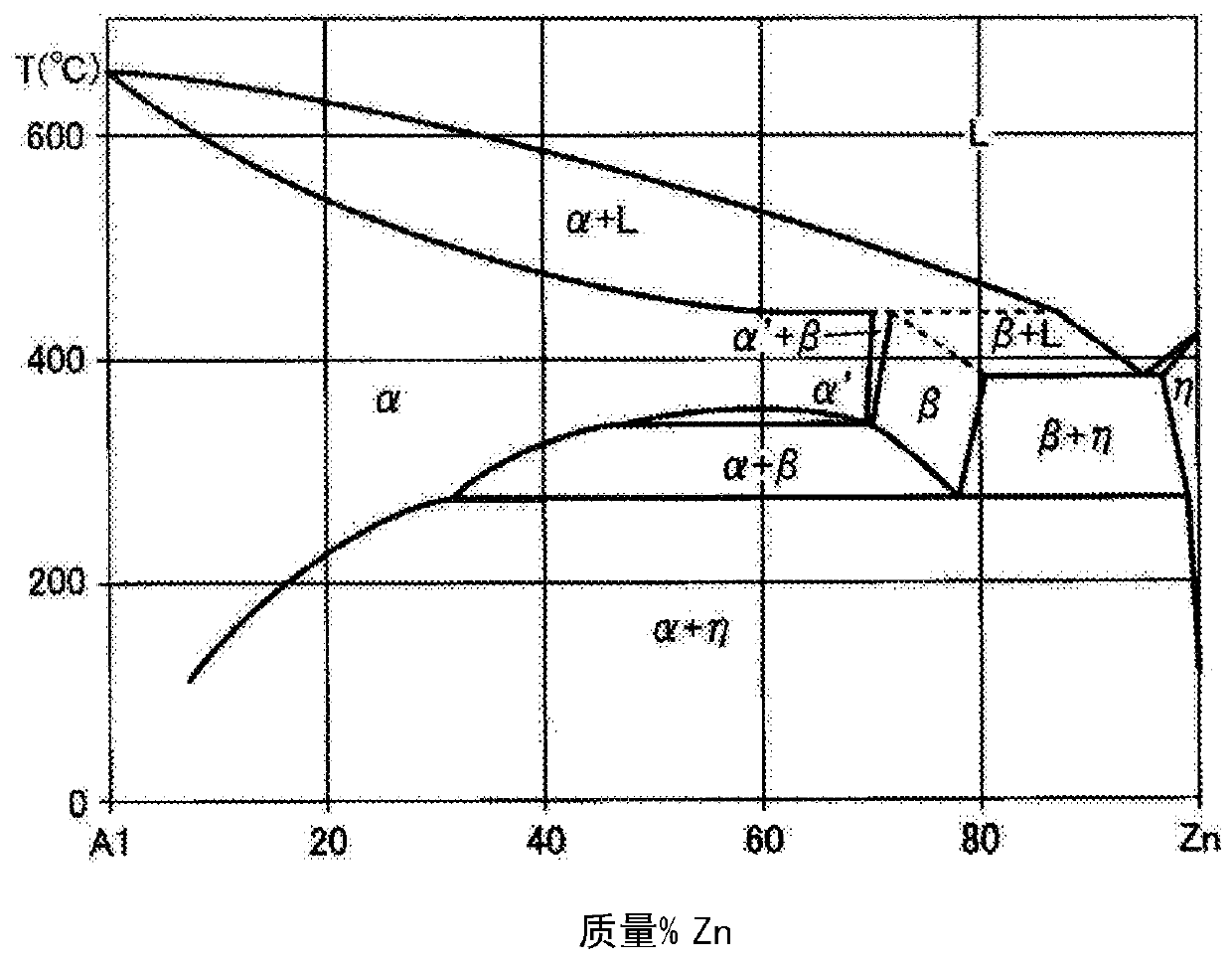

[0355] In order to obtain coatings with the chemical compositions shown in Tables 1-1 to 1-3, a coating bath was established in a vacuum melting furnace in the atmosphere using a predetermined amount of pure metal ingots. In the production of plated steel sheets, a batch type hot-dipping apparatus is used.

[0356] As comparative materials, Nos. 102 and 103 prepared commercially available Zn-Al-Mg-based plated steel sheets and hot-dip Zn-plated steel sheets. The thicknesses of the plating layers were all 20 μm.

[0357] As the coating bottom plate, use 3.2mm common material hot-rolled carbon steel 100×200mm (C=0.15%, Si=0.005%, Mn=0.55%, P=0.015%, S=0.005%), and the coating process will be performed soon Before, degreasing and pickling are carried out.

[0358] In the production of any sample, the same reduction treatment method is implemented for the plated bottom plate until the process of pulling it up after dipping in the plating bath. That is, at N 2 -H 2 (5%) (dew p...

Embodiment B

[0417] In order to obtain the coating with the chemical composition shown in Table 2-1, use a specified amount of pure metal ingot to establish a coating bath in the atmosphere in a vacuum melting furnace. In the production of plated steel sheets, a batch type hot-dipping apparatus is used.

[0418] As the coating bottom plate, use 3.2mm common material hot-rolled carbon steel 100×200mm (C=0.15%, Si=0.005%, Mn=0.55%, P=0.015, S=0.005%), just before the coating process , implement degreasing and pickling.

[0419] In the production of any sample, the same reduction treatment method is implemented for the plated bottom plate until the process of pulling it up after dipping in the plating bath. That is, at N 2 -H 2 (5%) (dew point - 40 ° below, oxygen concentration below 25ppm) environment, use electric heating to heat the plated steel plate from room temperature to 800 ° C, after 60 seconds, spray N 2 Cool to the bath temperature +10°C, then immediately immerse in the bath. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com