Material for promoting repairing of defect and deficiency tissue of teeth and preparation method of material

A technology for tissue repair and tooth application in dental preparations, dentistry, pharmaceutical formulations, etc., which can solve problems such as slow restoration, cracks at the interface between teeth and materials, and poor mechanical properties, so as to promote tooth tissue restoration. The preparation method is simple, The effect of low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1) Dissolve 0.05g of polyacrylic acid in 500g of distilled water to make a polyacrylic acid solution with a concentration of 0.1g / L;

[0032] 2) Dissolving 0.1 g of sodium β-phosphoglycerate in the polyacrylic acid solution of step 1) to obtain a mixed solution of 0.2 g / L sodium β-phosphoglycerate;

[0033] 3) Dissolve 0.2 g of potassium dihydrogen phosphate in the solution of step 2) to obtain a 0.4 g / L potassium dihydrogen phosphate mixed solution;

[0034] 4) Dissolving 0.01 g of enamel matrix protein in the solution of step 3) to obtain 0.02 g / L enamel matrix protein mixed solution 1;

[0035] 5) 0.2g of calcium chloride was dissolved in 500g of distilled water to obtain 0.4g / L of calcium chloride mixed solution II;

[0036] 6) Filter the mixed solution 1 of step 4) and the mixed solution 2 of step 5) respectively with a filter of 0.45 μm;

[0037] 7) Mixing equal volumes of the two solutions filtered in step 6) to obtain the material.

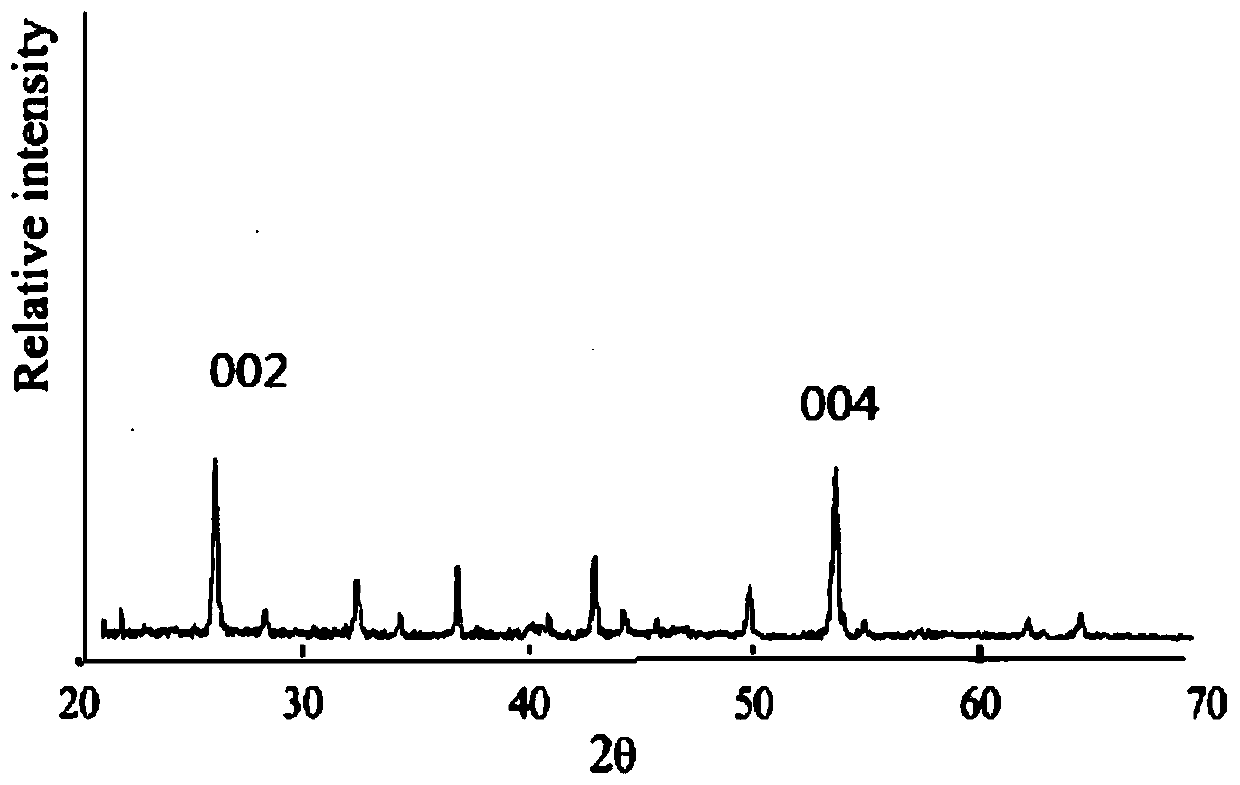

[0038] Gained material is...

Embodiment 2

[0041] 1) Dissolve 0.04g of polyacrylic acid in 500g of distilled water to make a polyacrylic acid solution with a concentration of 0.08g / L;

[0042] 2) Dissolving 0.4 g of sodium β-phosphoglycerate in the polyacrylic acid solution of step 1) to obtain a mixed solution of 0.8 g / L sodium β-phosphoglycerate;

[0043] 3) Dissolving 0.3 g of potassium dihydrogen phosphate in the solution of step 2) to obtain 0.06 g / L of enamel matrix protein mixed solution 1;

[0044] 4) Dissolving 0.02 g of enamel matrix protein in the solution of step 3) to obtain 0.04 g / L of enamel matrix protein mixed solution 1;

[0045] 5) Dissolve 0.3g calcium chloride in 500g distilled water to obtain 0.6g / L calcium chloride mixed solution II;

[0046] 6) Filter the mixed solution 1 of step 4) and the mixed solution 2 of step 5) respectively with a filter of 0.45 μm;

[0047] 7) Mixing equal volumes of the two solutions filtered in step 6) to obtain the material.

[0048] Gained material is tested, test...

Embodiment 3

[0051] 1) Dissolve 0.06g of polyacrylic acid in 500g of distilled water to make a polyacrylic acid solution with a concentration of 0.12g / L;

[0052] 2) Dissolving 0.54 g of sodium β-phosphoglycerate in the polyacrylic acid solution of step 1) to obtain a mixed solution of 1.08 g / L of sodium β-phosphoglycerate;

[0053] 3) Dissolving 0.5 g of potassium dihydrogen phosphate in the solution of step 2) to obtain a 1.0 g / L potassium dihydrogen phosphate mixed solution;

[0054] 4) Dissolving 0.04 g of enamel matrix protein in the solution of step 3) to obtain 0.08 g / L of enamel matrix protein mixed solution 1;

[0055] 5) the calcium chloride of 0.4g is dissolved in 500g distilled water, obtains the calcium chloride mixed solution 2 of 0.8g / L;

[0056] 6) Filter the mixed solution 1 of step 4) and the mixed solution 2 of step 5) respectively with a filter of 0.45 μm;

[0057] 7) Mixing equal volumes of the two solutions filtered in step 6) to obtain the material.

[0058] Gaine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com