Loaded ultra-small Prussian blue analog and preparation method and application thereof

A technology of Prussian blue and analogs, applied in the field of supported ultra-small Prussian blue analogs and their preparation, can solve problems such as unseen Prussian blue structures, achieve simple process, realize large-scale production of catalysts, and mild reaction conditions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

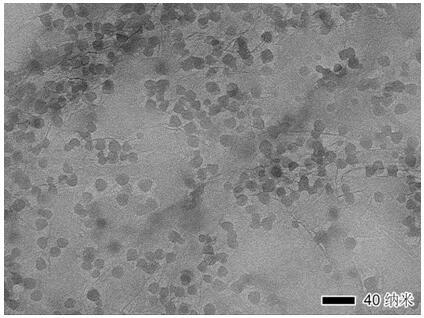

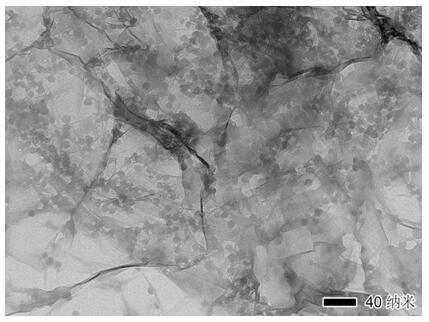

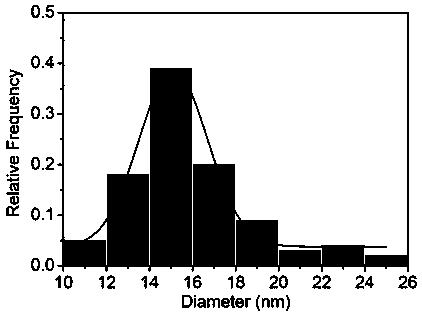

[0037] A preparation method of graphene-loaded ultra-small Prussian blue analogues specifically comprises the following steps:

[0038] a) The trivalent metal compound, the divalent metal compound, the first solvent, the ligand and graphene are mixed and reacted and washed to prepare the graphene-loaded ultra-small Prussian blue analogue; the trivalent metal compound, the divalent metal source compound, The weight ratio of the first solvent, ligand and graphene is 5:5:4000:10:1; the reaction conditions are: reaction temperature 100°C, reaction time 2 days;

[0039] b) Disperse the graphene-loaded ultra-small Prussian blue analogue in the first solvent, and add a reducing agent and an alkaline solution to mix and react to prepare the graphene-loaded ultra-small Prussian blue analogue after graphene reduction; graphene-loaded The weight ratio of the ultra-small Prussian blue analogue, the first solvent, the reducing agent, and the basic drug is 4000:50000:150:1; the reaction con...

Embodiment 2

[0043] A preparation method of graphene-loaded ultra-small Prussian blue analogues specifically comprises the following steps:

[0044] a) The trivalent metal compound, the divalent metal compound, the first solvent, the ligand and graphene are mixed and reacted and washed to prepare the graphene-loaded ultra-small Prussian blue analogue; the trivalent metal compound and the divalent metal source compound, The weight ratio of the first solvent, ligand and graphene is 1:5:1000:10:1; the reaction conditions are: reaction temperature 10°C, reaction time 7 days;

[0045] b) Disperse the graphene-loaded ultra-small Prussian blue analogue in the first solvent, and add a reducing agent and an alkaline solution to mix and react to prepare the graphene-loaded ultra-small Prussian blue analogue after graphene reduction; graphene-loaded The weight ratio of the ultra-small Prussian blue analogue, the first solvent, the reducing agent, and the basic drug is 5000:50000:200:1; the reaction c...

Embodiment 3

[0049] A preparation method of graphene-loaded ultra-small Prussian blue analogues specifically comprises the following steps:

[0050] a) The trivalent metal compound and the divalent metal compound, the first solvent, the ligand and graphene are mixed and reacted and washed to prepare the graphene-loaded ultra-small Prussian blue analogue; the trivalent metal compound and the divalent metal source compound, The weight ratio of the first solvent, ligand and graphene is 10:9:5000:10:1; the reaction conditions are: reaction temperature 180°C, reaction time 1 day;

[0051] b) Dispersing the graphene-loaded ultra-small Prussian blue analog in the first solvent, adding a reducing agent and an alkaline solution to mix and react to prepare the graphene-loaded ultra-small Prussian blue analog after graphene reduction. The weight ratio of the ultra-small Prussian blue analogue loaded on graphene, the first solvent, the reducing agent, and the basic drug is 10000:50000:150:1; the react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com