Treating method for silver electrodes used for ion chromatography electrochemistry amperometric detection

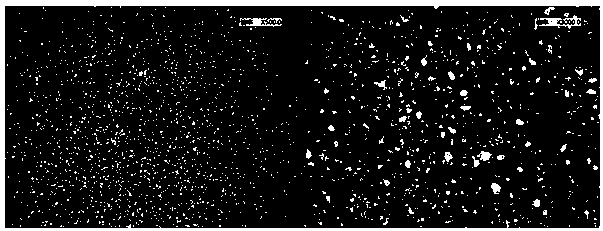

A technology of amperometric detection and ion chromatography, which is applied in the processing field of silver electrodes for electrochemical amperometric detection of ion chromatography, can solve the problems of affecting the detection effect of electrochemical detectors, short service life of silver electrodes, small detection current value, etc., and achieves improvement The effect of detection current upper limit and detection life, large real area and strong inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

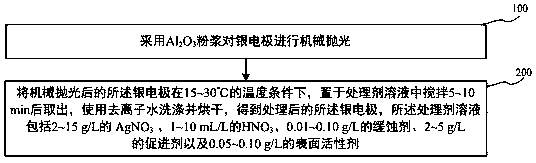

[0063] (1) According to Al 2 o 3 The volume ratio of powder and deionized water is 1:3 to configure Al 2 o 3 Slurry.

[0064] (2) Evenly drop 4 drops of the Al on the polishing cloth 2 o 3 slurry, the cleaned silver electrode was polished on the polishing cloth at a constant speed for 5 min, and the polishing cloth and the silver electrode were cleaned with deionized water.

[0065] (3) Repeat the above and evenly drop 4 drops of the Al on the polishing cloth 2 o 3 slurry, the cleaned silver electrode was polished on the polishing cloth at a constant speed for 5 min, and the polishing cloth and the silver electrode were cleaned 8 times with deionized water.

[0066] (4) Put the mechanically polished silver electrode in the treatment agent solution at a temperature of 15° C., stir for 5 minutes, take it out, wash it with deionized water and dry it to obtain the treated silver electrode. The above treatment agent solution includes 2g / L AgNO 3 , 1 mL / L of HNO 3 , 0.01 ...

Embodiment 2

[0068] (1) According to Al 2 o 3 The volume ratio of powder and deionized water is 1:4 to configure Al 2 o 3 Slurry.

[0069] (2) Evenly drop 5 drops of the Al on the polishing cloth 2 o 3 slurry, the cleaned silver electrode was polished on the polishing cloth at a constant speed for 6 min, and the polishing cloth and the silver electrode were cleaned with deionized water.

[0070] (3) Repeat the above and evenly drop 5 drops of the Al on the polishing cloth 2 o 3 slurry, the cleaned silver electrode was polished on the polishing cloth at a constant speed for 6 min, and the polishing cloth and the silver electrode were cleaned 9 times with deionized water.

[0071] (4) Put the mechanically polished silver electrode in the treatment agent solution for 7 minutes at a temperature of 20° C., take it out, wash it with deionized water and dry it to obtain the treated silver electrode. The treatment agent solution includes 10g / L of AgNO 3 , 1mL / L of HNO 3 , 0.04 g / L corro...

Embodiment 3

[0073] (1) According to Al 2 o 3 The volume ratio of powder and deionized water is 1:4 to configure Al 2 o 3 Slurry.

[0074] (2) Evenly drop 5 drops of the Al on the polishing cloth 2 o 3 slurry, the cleaned silver electrode was polished on the polishing cloth at a constant speed for 6 minutes, and the polishing cloth and the silver electrode were cleaned with deionized water.

[0075] (3) Repeat the above and evenly drop 5 drops of the Al on the polishing cloth 2 o 3 slurry, polishing the cleaned silver electrode on the polishing cloth at a constant speed for 6 minutes, and cleaning the polishing cloth and the silver electrode with ionized water 10 times.

[0076](4) The mechanically polished silver electrode was placed in the treatment agent solution at a temperature of 25° C., stirred for 9 minutes, taken out, washed with deionized water and dried to obtain the treated silver electrode. The treatment agent solution includes 15g / L of AgNO 3 , 10 mL / L of HNO 3 , 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com