A kind of PBS ring-core optical fiber for amplifying OAM light beam and its preparation method

A ring core and optical fiber technology, applied in the field of optical fiber, can solve the problems of inability to transmit and amplify OAM beams, and achieve the effects of high refractive index difference, large mode capacity, and large optical fiber bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

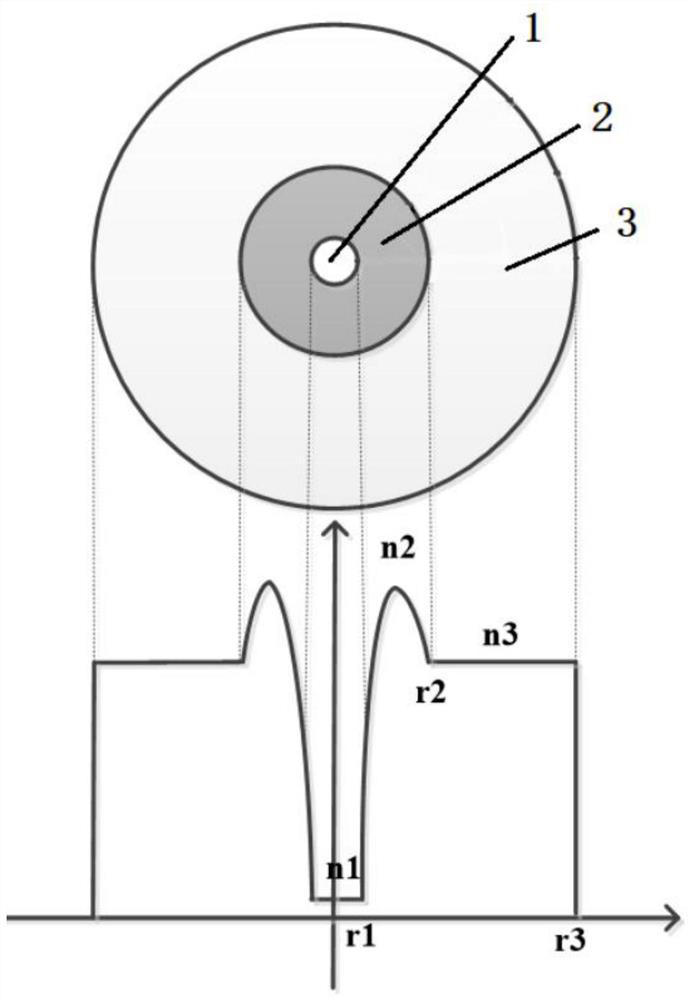

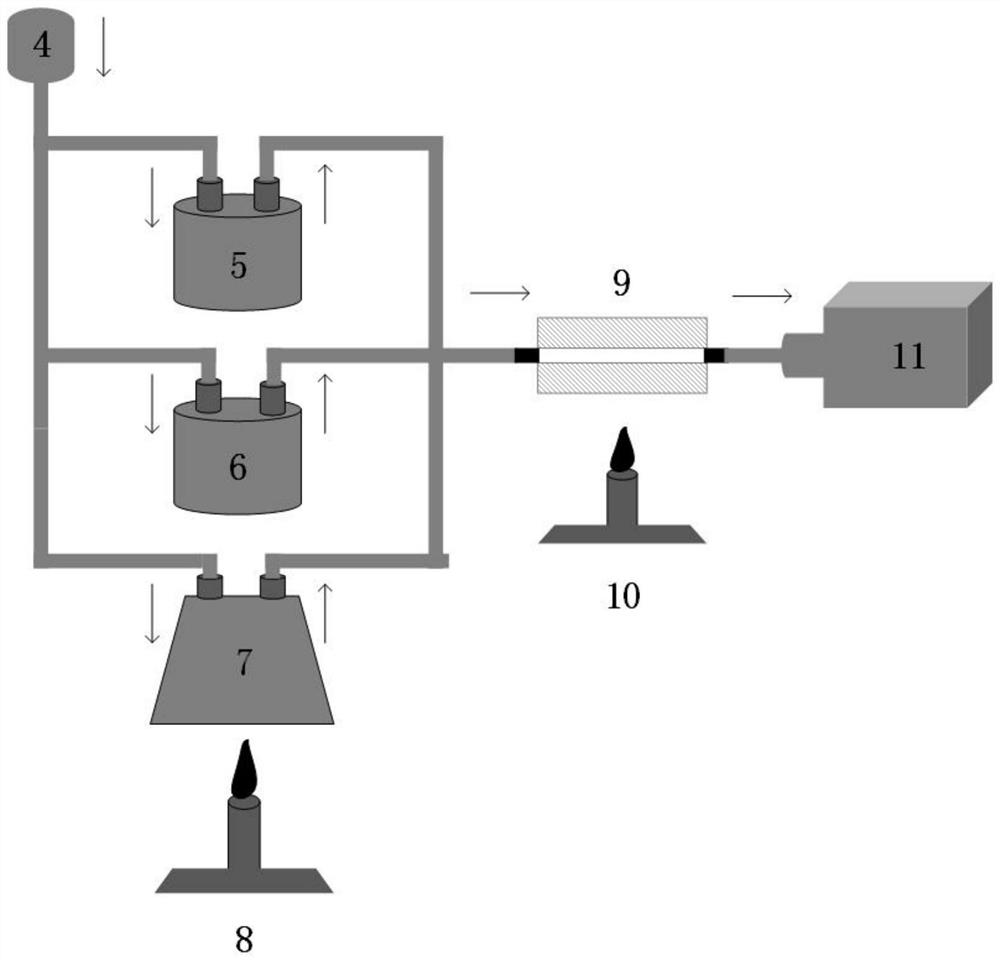

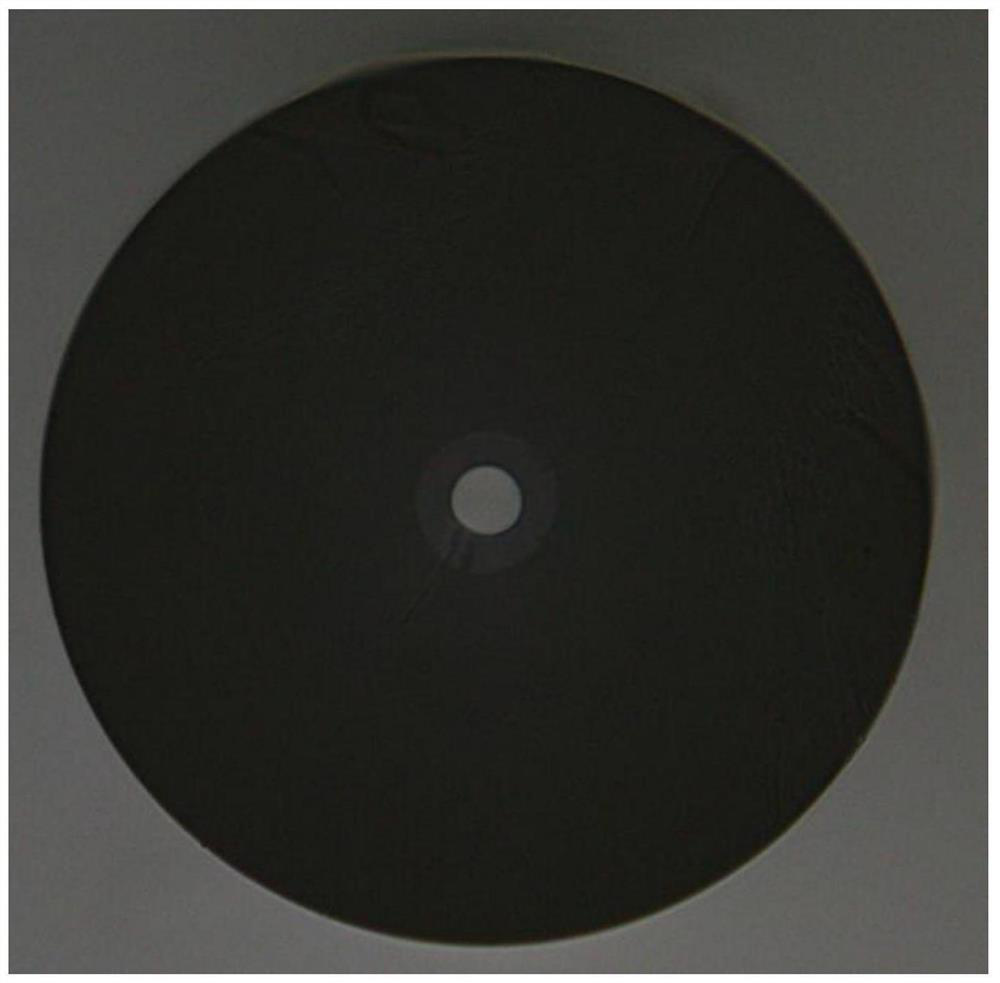

[0038] Such as figure 1 , figure 2 , image 3 Shown, a kind of PbS ring-core fiber that amplifies OAM light beam, described PbS ring-core fiber comprises fiber air core 1, PbS doped ring 2 and cladding 3, and the main component of described PbS doped ring 2 is PbS and quartz , the PbS ring-core fiber is prepared by adding a PbS powder high-temperature vaporization deposition process in the improved chemical vapor deposition process, and changing the timing of PbS powder vaporization to prepare a ring-shaped PbS-doped silica fiber, and obtaining the PbS ring-core of the amplified OAM beam optical fiber.

[0039] Further, the high-temperature vapor deposition process specifically includes: using a high temperature of 1700°C to heat the raw material, so that the PbS powder vaporizes into the quartz substrate tube after reaching the boiling point at 1281°C; the PbS ring-core optical fiber is only doped in the ring Matching structure of heterogeneous PbS material; the PbS ring-...

Embodiment 2

[0048] Such as figure 1 , figure 2 , image 3 Shown, a kind of PbS ring-core fiber that amplifies OAM light beam, described PbS ring-core fiber comprises fiber air core 1, PbS doped ring 2 and cladding 3, and the main component of described PbS doped ring 2 is PbS and quartz , the PbS ring-core fiber is prepared by adding a PbS powder high-temperature vaporization deposition process in the improved chemical vapor deposition process, and changing the timing of PbS powder vaporization to prepare a ring-shaped PbS-doped silica fiber, and obtaining the PbS ring-core of the amplified OAM beam optical fiber.

[0049] Further, the high-temperature vapor deposition process specifically includes: heating the raw material at a high temperature of 1900°C, so that the PbS powder vaporizes into the quartz substrate tube after reaching the boiling point at 1281°C; the PbS ring-core optical fiber is only doped in the ring Matching structure of heterogeneous PbS material; the PbS ring-cor...

Embodiment 3

[0058] Such as figure 1 , figure 2 , image 3 Shown, a kind of PbS ring-core fiber that amplifies OAM light beam, described PbS ring-core fiber comprises fiber air core 1, PbS doped ring 2 and cladding 3, and the main component of described PbS doped ring 2 is PbS and quartz , the PbS ring-core fiber is prepared by adding a PbS powder high-temperature vaporization deposition process in the improved chemical vapor deposition process, and changing the timing of PbS powder vaporization to prepare a ring-shaped PbS-doped silica fiber, and obtaining the PbS ring-core of the amplified OAM beam optical fiber.

[0059]Further, the high-temperature vapor deposition process specifically includes: heating the raw material at a high temperature of 1800°C, so that the PbS powder vaporizes into the quartz substrate tube after reaching the boiling point at 1281°C; the PbS ring-core optical fiber is only doped in the ring Matching structure of heterogeneous PbS material; the PbS ring-core...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com