Thinning method of III-V group semiconductor wafer

A III-V, semiconductor technology, used in semiconductor/solid-state device manufacturing, grinding machine components, and workpiece feed motion control, etc., can solve the problem of limited space for process parameter optimization, clogging of grinding fluid pipelines, and rough backside. In order to reduce the single-chip grinding time, increase the grinding rate, and reduce the operation risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

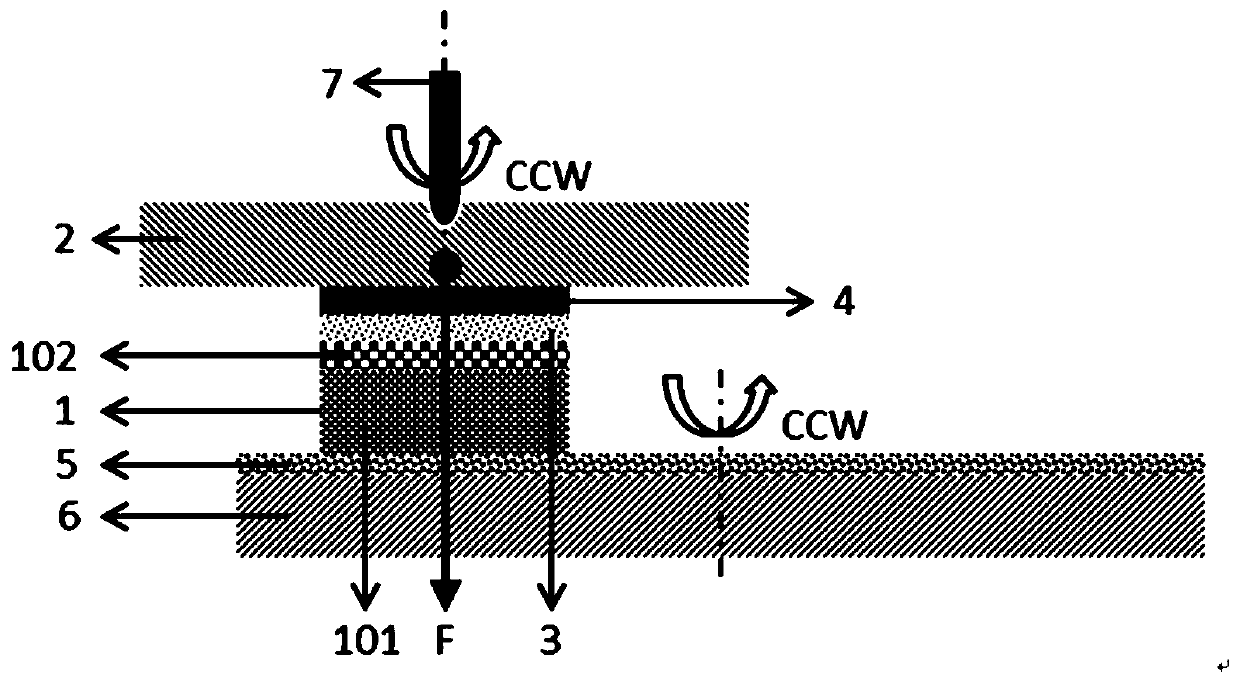

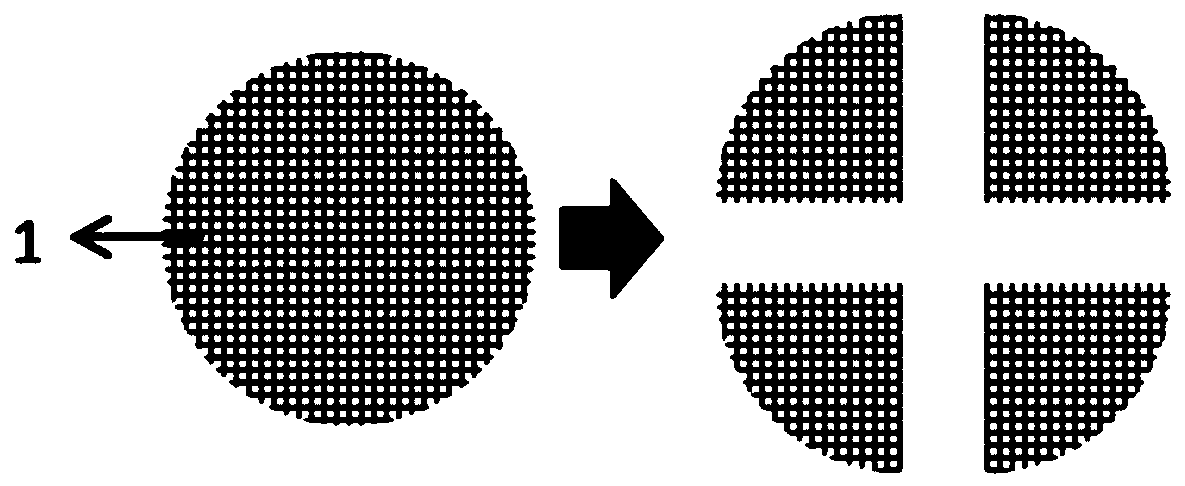

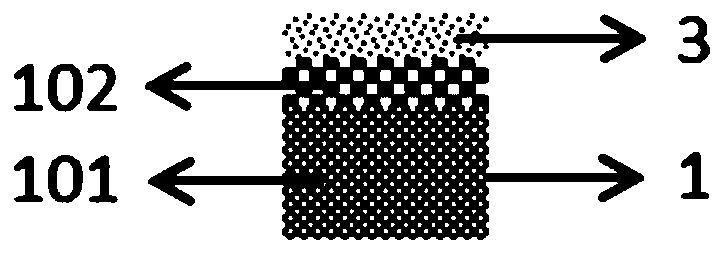

[0032] Aiming at the problem that the existing III-V semiconductor wafer thinning process is difficult to improve efficiency under the premise of ensuring quality, the present invention proposes a III-V semiconductor wafer that can improve production efficiency under the premise of ensuring quality Thinning method, by subdividing the whole wafer semi-finished product into pieces and performing back grinding to greatly increase the grinding rate; specifically, the III-V group semiconductor wafer has a plurality of device units divided by a plurality of dividing lines For the front side and the back side opposite to the front side, first divide the III-V group semiconductor wafer into a plurality of independent small wafers; then simultaneously grind the back sides of the plurality of independent small wafers, To reduce the thickness of the small wafer.

[0033] After a lot of experiments, the inventor found that: after the whole wafer is divided into multiple independent small ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com