Radial all-inorganic perovskite nanomaterial and preparation method thereof

A nano-material and radial technology, applied in the field of perovskite materials and its preparation, can solve the problems of many surface defects, unfavorable effective separation of electrons and holes, and instability of zero-dimensional perovskite materials, achieving large specific surface area, The effect of improving photoelectric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] (1) 0.1g of cesium carbonate (0.3mmol), 0.3mL (1mmol) of oleic acid and 3.75mL of octadecene were fully reacted and dissolved under an inert atmosphere at a temperature of 120°C to obtain solution I;

[0048] (2) Mix 69mg (0.188mmol) of lead bromide, 0.5mL (1.5mmol) of oleic acid and 10mL (0.03mol) of oleylamine, and fully dissolve them under an inert atmosphere at a temperature of 120°C to obtain solution II;

[0049] (3) Raise the temperature of solution II to 160°C, inject 0.4mL of solution I into solution II (10.5mL), and continue to react and stir;

[0050] (4) Keep stirring at the same temperature for 12 hours to obtain the reaction solution, and finally centrifuge, separate and wash to obtain the final product.

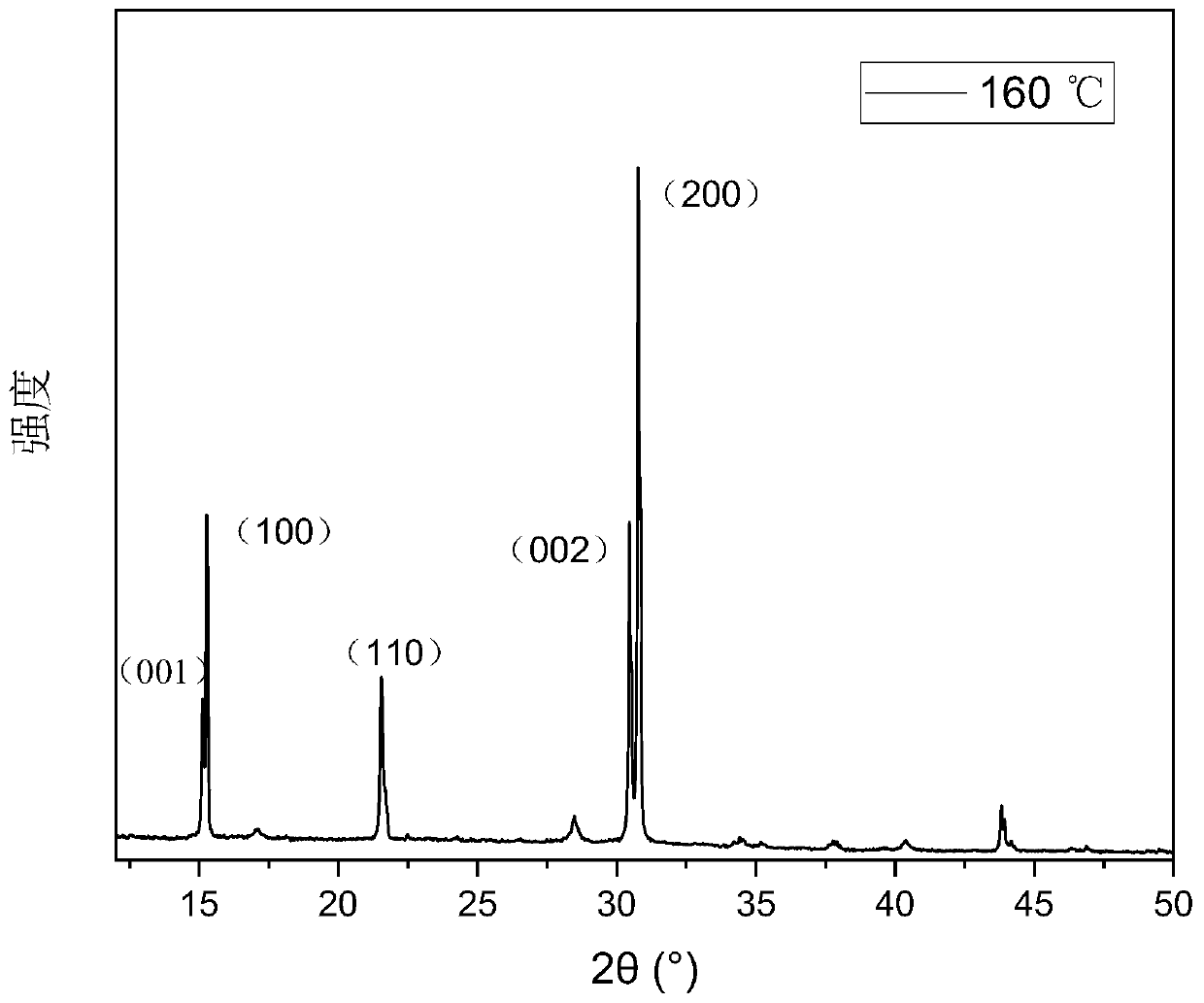

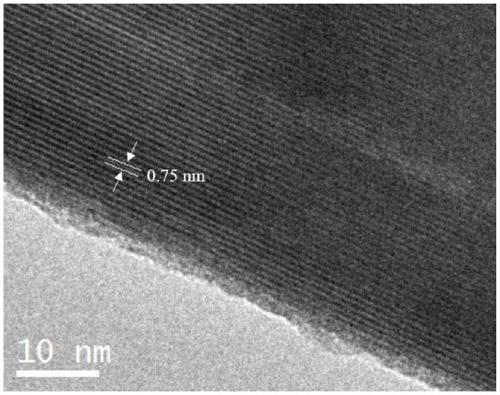

[0051] figure 1For the XRD collection of products prepared in this embodiment, it can be confirmed by observing the XRD collection that the product is composed of CsPbBr 3 , Judging from the intensity of diffraction peaks in XRD, the main growth planes...

Embodiment 2

[0067] (1) 0.1g (0.3mmol) cesium carbonate, 0.35mL (1.1mmol) oleic acid and 3.75mL octadecene were fully reacted and dissolved under an inert atmosphere at a temperature of 120°C to obtain solution I;

[0068] (2) Dissolve 69mg (0.188mmol) of lead bromide and 0.5mL (1.5mmol) of oleic acid in 10mL (0.03mol) of oleylamine under an inert atmosphere at a temperature of 120°C to obtain solution II;

[0069] (3) Raise the temperature of solution II to 150°C, inject 0.4mL of solution I into solution II, and continue the reaction and stirring;

[0070] (4) Maintain the same temperature and continue to stir the reaction for 12 hours to obtain the reaction solution, and finally obtain the product after centrifugation, separation and washing.

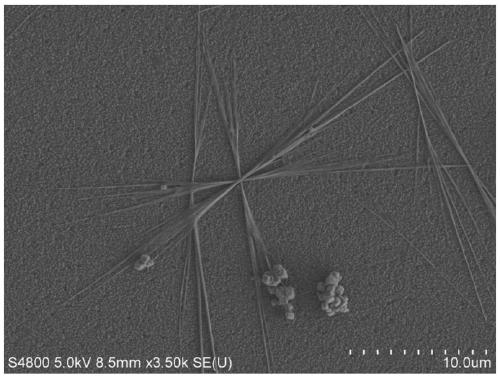

[0071] Figure 6 The SEM image of the product prepared for this example, as can be seen from the figure, the product CsPbBr prepared at 150 ° C 3 It has a unilateral radial perovskite structure and is composed of about 10 perovskite nanowires. T...

Embodiment 3

[0073] (1) 0.1g (0.3mmol) cesium carbonate, 0.35mL (1.1mmol) oleic acid and 3.75mL octadecene were fully reacted and dissolved under an inert atmosphere at a temperature of 120°C to obtain solution I;

[0074] (2) Dissolve 69mg (0.188mmol) of lead bromide and 0.5mL (1.5mmol) of oleic acid in 5mL (0.015mol) of oleylamine under an inert atmosphere at a temperature of 120°C to obtain solution II;

[0075] (3) Raise the temperature of solution II to 180°C, inject 0.4mL of solution I into solution II, and continue to react and stir;

[0076] (4) Maintain the same temperature and continue to stir the reaction for 12 hours to obtain the reaction solution, and finally obtain the product after centrifugation, separation and washing.

[0077] After testing, the morphology of the product prepared in this example is basically the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Central particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com