Preparation method of isopentenyl alcohol

A technology of prenol and butene, which is applied in the field of preparation of prenol, can solve the problem of low effective conversion rate of raw materials, and achieve the effect of one-time conversion rate improvement, good contact effect and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A kind of preparation method of isopentenol is carried out by synthesis reactor, comprises the steps:

[0036] Step 1. Weigh the main catalyst and the co-catalyst respectively according to the weight ratio, mix the main catalyst and the co-catalyst uniformly and set aside for use, wherein the weight of 5% Pd / C, tetramethylthiourea and zinc acetate is 1:2:2 ;

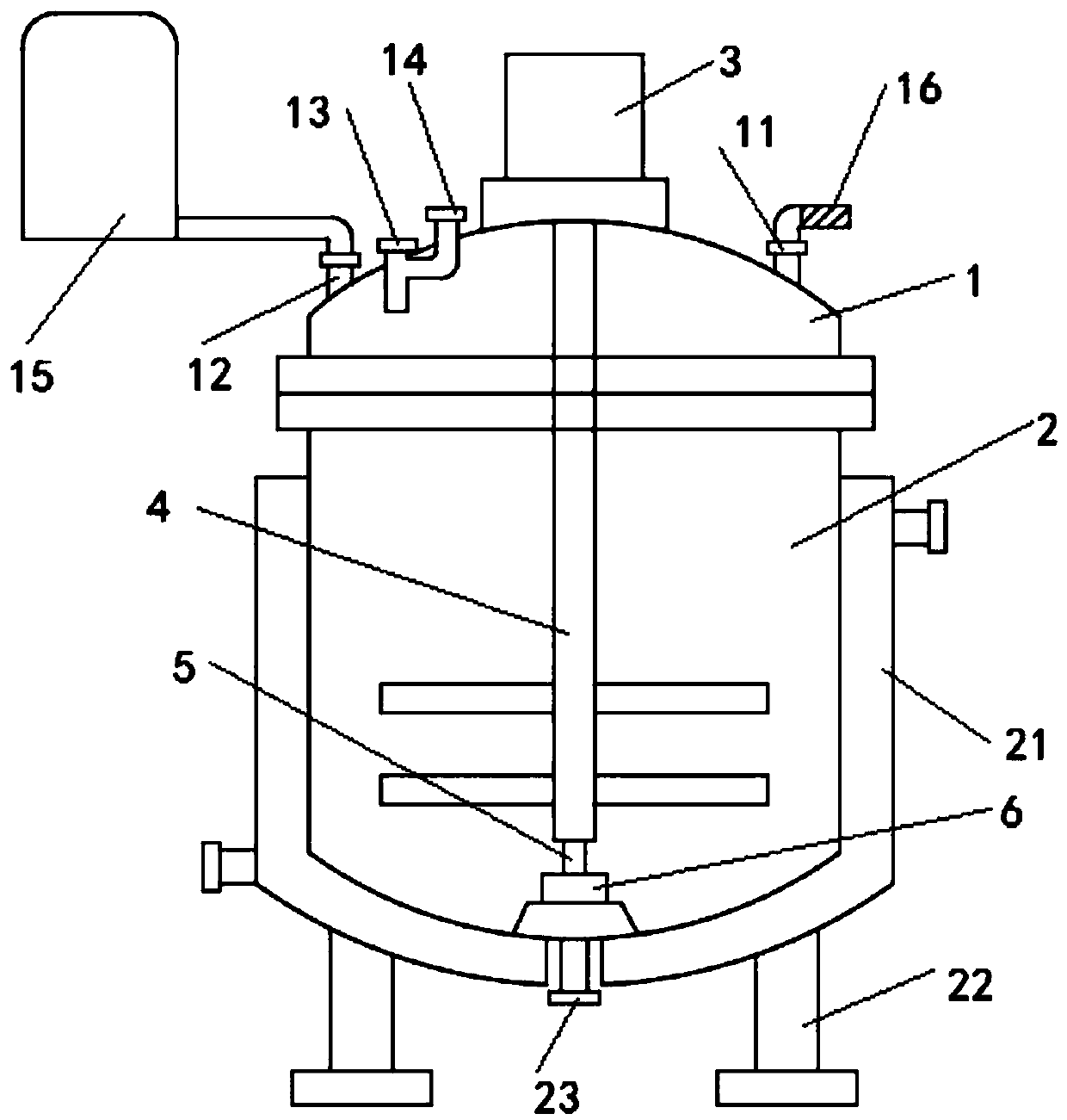

[0037] Step 2: Input heat-conducting oil into the oil guide layer 21, heat the kettle body 2 to 90°C, open the air inlet 11 and the air outlet 12, and input hydrogen into the reaction kettle. When the reaction kettle is filled with hydrogen, put the The homogeneous mixture 1.5kg of main catalyst and procatalyst obtained is added in the reactor through catalyst inlet 13, close catalyst inlet 13, open raw material inlet 14, 50kg reaction raw material 3-methyl-3-butene-1-alcohol is added completely After the reactor, close the raw material inlet 14;

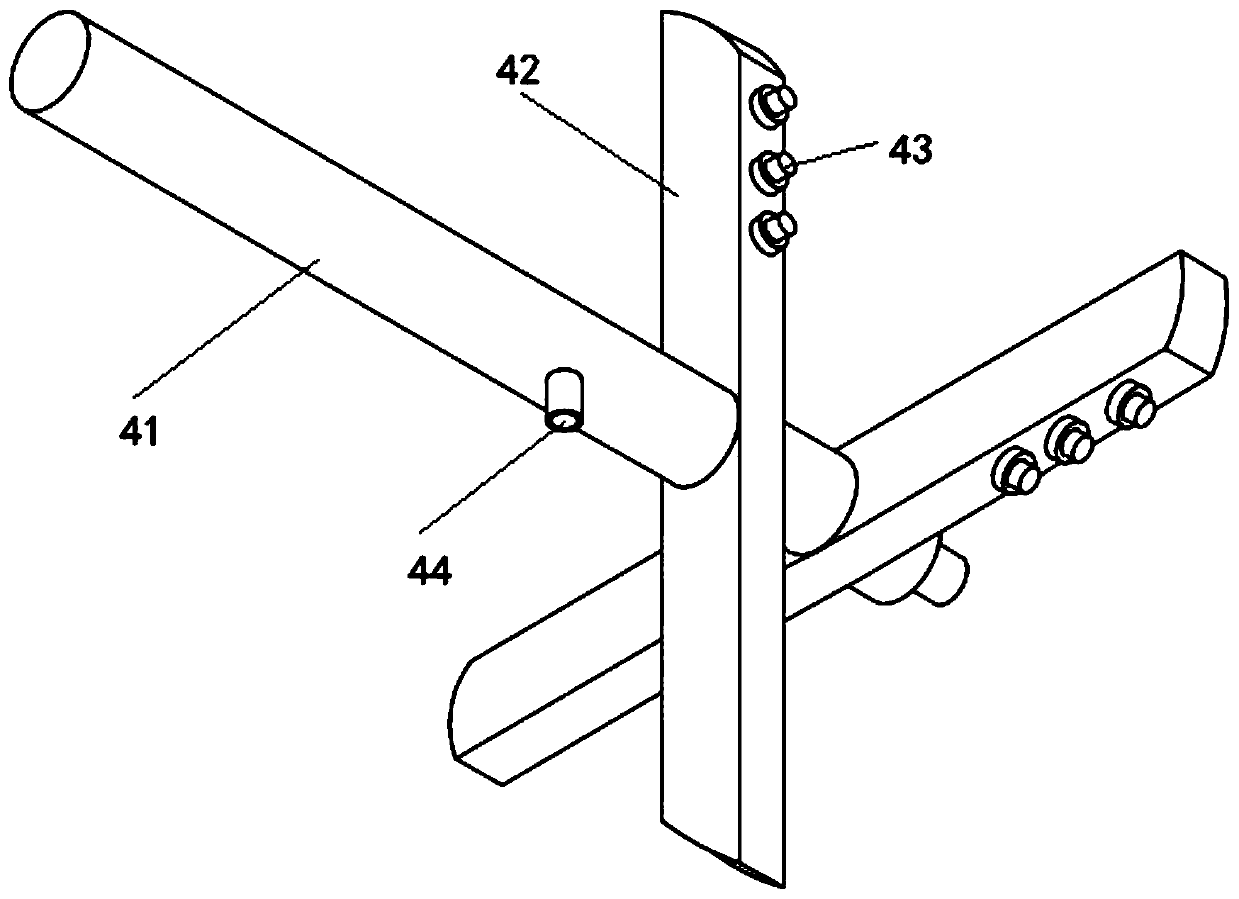

[0038] Step 3, turn on the condensing device 15, the submersible...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com