An electronically controlled liquid crystal dimming film with low driving voltage

A liquid crystal dimming film and electronic control technology, applied in optics, nonlinear optics, instruments, etc., can solve the problems of difficult flexible large-area processing, poor flexibility, low tear strength, etc., to reduce anchoring effect and response speed Fast, excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] 2. The preparation method of the liquid crystal dimming film provided by the invention comprises the following steps:

[0048] (1) Mix the liquid crystal material, epoxy monomer, epoxy curing agent, accelerator, liquid crystal UV light polymerizable monomer, initiator and spacer particles uniformly according to the required ratio, and place the formed isotropic liquid material A thin film is formed between a conductive film coated with indium tin oxide (ITO).

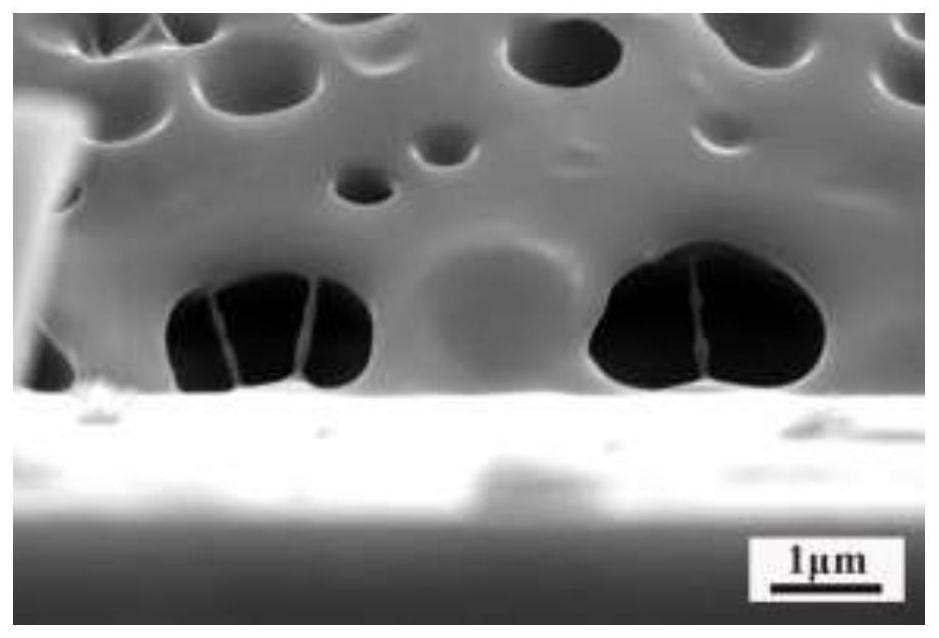

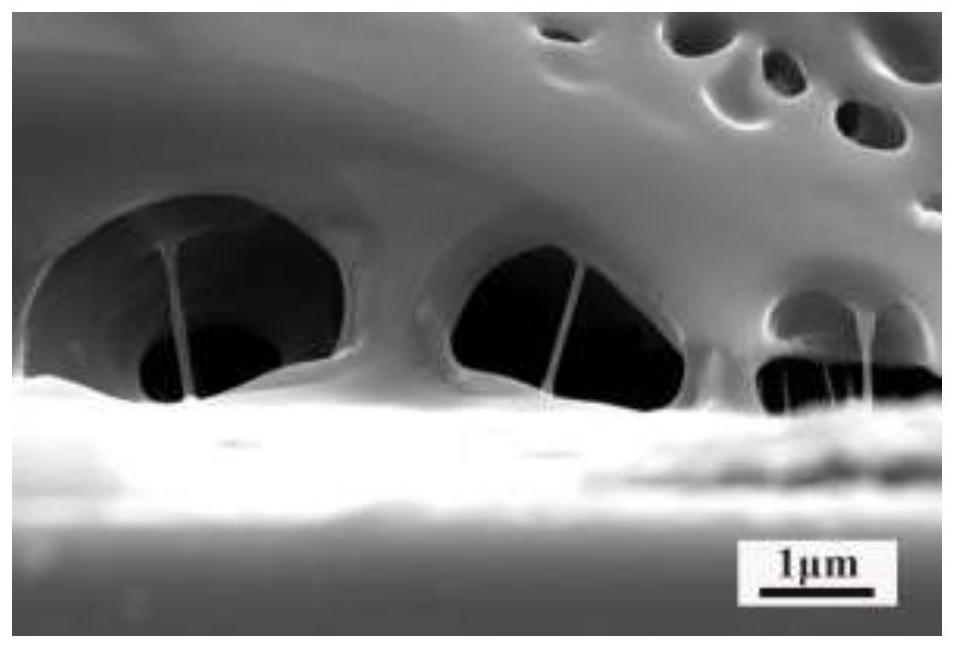

[0049] (2) Thermally polymerize the film, initiate the cross-linking reaction of epoxy monomer and epoxy curing agent through thermal polymerization to form a polymer matrix, form a microphase separation with liquid crystal photopolymerizable monomer and liquid crystal, and obtain a conductive film . The specific conditions of the thermal polymerization are as follows: within the range of room temperature to 100° C., the polymerization reaction takes 1 to 24 hours.

[0050] (3) Applying an electric field to the...

Embodiment

[0054] 1. Material description:

[0055] (1) The cholesteric liquid crystal material used in this embodiment is obtained by adding a chiral additive S811 to the nematic liquid crystal E8. Wherein, the mass ratio of E8 and S811 is 97:3; the preparation method is as follows: mix E8 and S811 and stir well. The molecular structure and content of each component of the nematic liquid crystal E8 are shown in Table 1.

[0056] Table 1 Molecular structure and content comparison table of each component of liquid crystal material E8

[0057]

[0058]

[0059] (2) The molecular structures of the materials involved in this embodiment are shown in Table 2.

[0060] Molecular structure comparison table of each material used in Table 2

[0061]

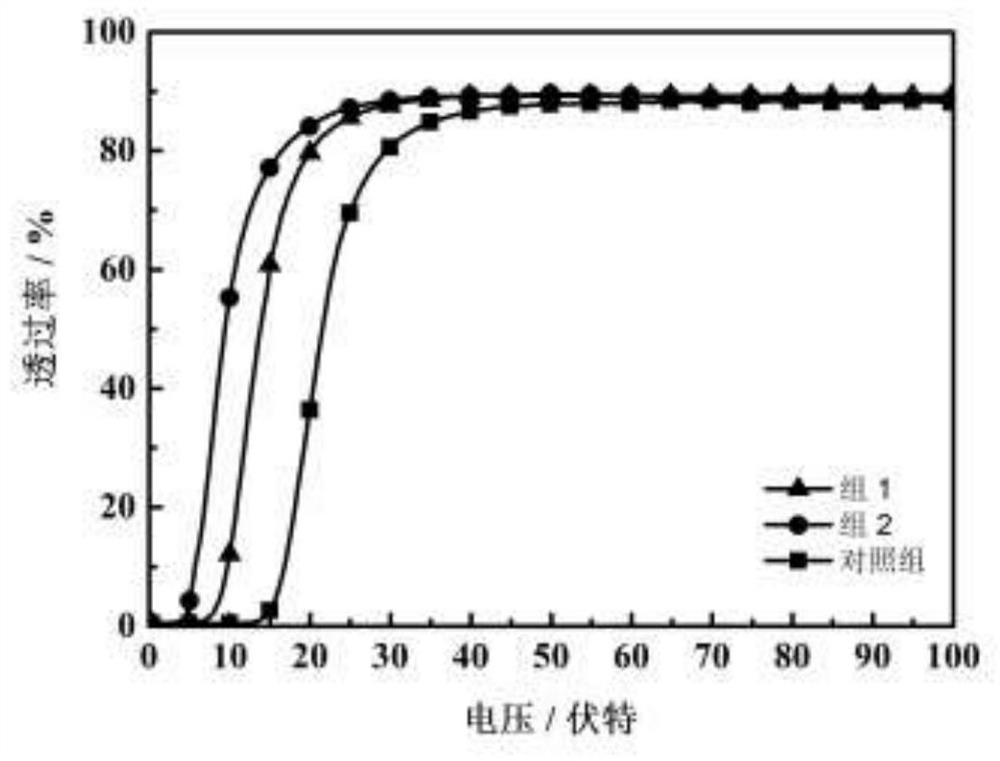

[0062] 2. Prepare the liquid crystal dimming films required by the two groups, and set up a control group at the same time. The materials required for each group are shown in Table 3.

[0063] Table 3 formula ratio table of each group

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com