Anti-high salt drag reducer and preparation method thereof

A drag reducer and anti-high salt technology, which is applied in the preparation of anti-high salt drag reducer, and in the field of anti-high salt drag reducer, can solve problems such as difficult to meet, unsatisfactory drag reduction rate and kinematic viscosity of drag reducer, Achieve the effect of wide application range and good salt resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

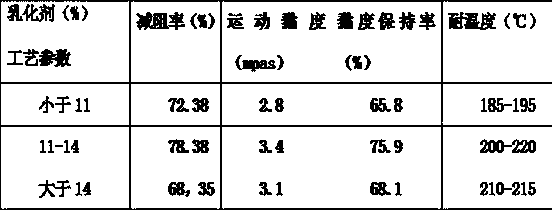

Examples

Embodiment 1

[0025] An anti-high salt drag reducing agent, its raw materials are as follows by mass percentage: 15% acrylamide, 3% polyvinylpyrrolidone, 5% 2-acrylamide-2-methylpropanesulfonic acid, 15% acrylic acid, 1% ammonium sulfate , Sodium Hydroxide 2%, Calcium Chloride 1%, Emulsifier 11%, Oil Phase Solvent 5%, Gel Breaker 5%, Deionized Water 37%.

[0026] Specifically, the emulsifier is Tween 80, which is a light yellow to orange-yellow viscous liquid, and its kinematic viscosity is 350mm at 25°C. 3 / s.

[0027] Specifically, the oil phase solvent is any two combinations of kerosene, mineral oil and silicone oil, and the combination ratio is 1:1.

[0028] Specifically, the gel breaker is an active enzyme gel breaker, and the gel breaker rate exceeds 99%.

[0029] The present invention also provides a preparation method of anti-high salt drag reducer, comprising the following steps:

[0030] S1: Taking materials, mixing acrylamide, polyvinylpyrrolidone, 2-acrylamide-2-methylpropan...

Embodiment 2

[0041] An anti-high salt drag reducer, its raw materials are as follows by mass percentage: 20% acrylamide, 4% polyvinylpyrrolidone, 7% 2-acrylamide-2-methylpropanesulfonic acid, 17% acrylic acid, 2% ammonium sulfate , 4% sodium hydroxide, 2% calcium chloride, 13% emulsifier, 6% oil phase solvent, 6% gel breaker, 19% deionized water.

[0042] Specifically, the emulsifier is Tween 80, which is a light yellow to orange viscous liquid, and its kinematic viscosity is 450mm at 25°C. 3 / s.

[0043] Specifically, the oil phase solvent is any two combinations of kerosene, mineral oil and silicone oil, and the combination ratio is 1:1.

[0044] Specifically, the gel breaker is an active enzyme gel breaker, and the gel breaker rate exceeds 99%.

[0045] The present invention also provides a preparation method of anti-high salt drag reducer, comprising the following steps:

[0046] S1: Taking materials, mixing acrylamide, polyvinylpyrrolidone, 2-acrylamide-2-methylpropanesulfonic acid...

Embodiment 3

[0057] An anti-high salt drag reducer, its raw materials are as follows by mass percentage: 25% acrylamide, 5% polyvinylpyrrolidone, 5% 2-acrylamide-2-methylpropanesulfonic acid, 20% acrylic acid, 2% ammonium sulfate , 6% sodium hydroxide, 3% calcium chloride, 14% emulsifier, 5% oil phase solvent, 5% gel breaker, 10% deionized water.

[0058] Specifically, the emulsifier is Tween 80, which is a light yellow to orange-yellow viscous liquid, and its kinematic viscosity is 550mm at 25°C. 3 / s.

[0059] Specifically, the oil phase solvent is any two combinations of kerosene, mineral oil and silicone oil, and the combination ratio is 1:1.

[0060] Specifically, the gel breaker is an active enzyme gel breaker, and the gel breaker rate exceeds 99%.

[0061] The present invention also provides a preparation method of anti-high salt drag reducer, comprising the following steps:

[0062] S1: Taking materials, mixing acrylamide, polyvinylpyrrolidone, 2-acrylamide-2-methylpropanesulfon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com