Steel strand external stay cable structure system for wind tower and manufacturing and installation method thereof

A technology of steel strand and cable structure, which is applied in basic structure engineering, installation/support configuration of wind turbines, towers, etc., to achieve the effect of flexible scheme adjustment, reduction of construction cost, and guarantee of construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] A steel strand external cable structure system for wind towers:

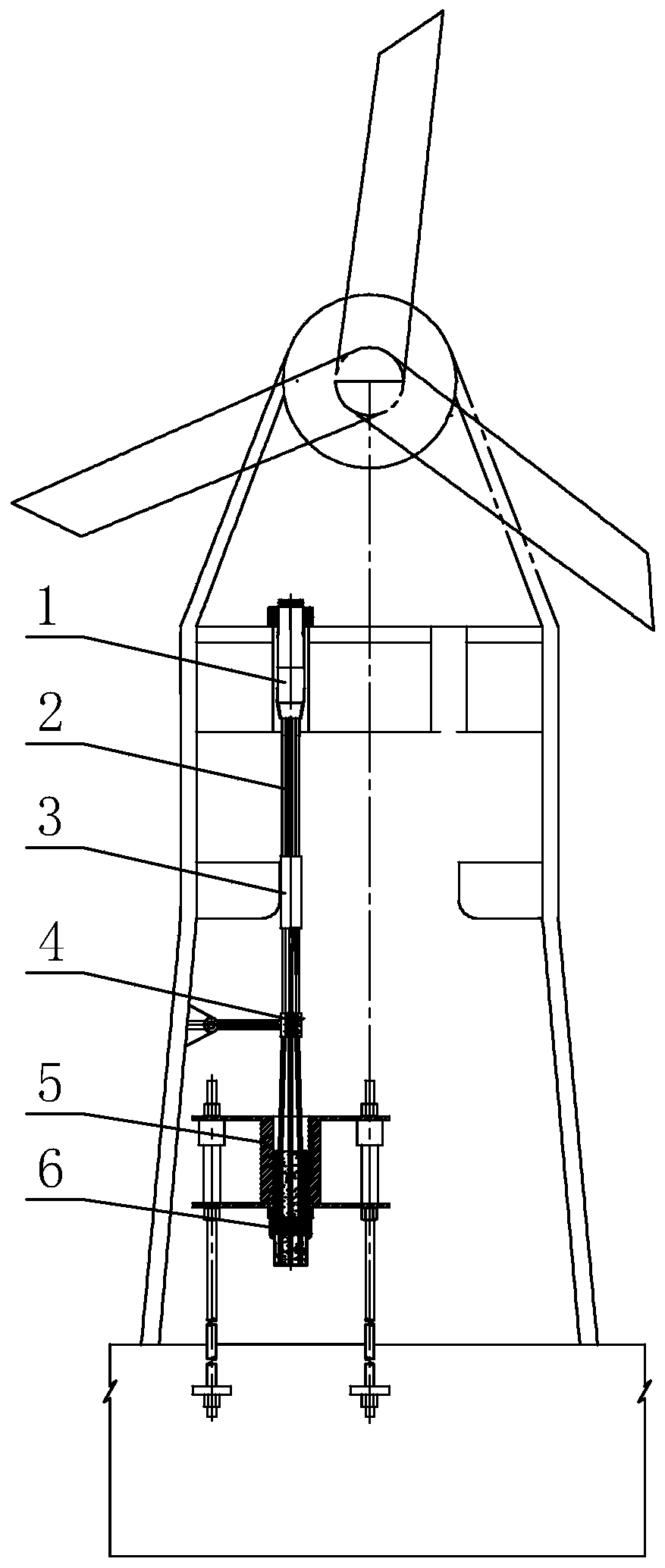

[0067] Such as figure 1 As shown, the external cable structure system of the steel strand for the wind tower includes a combined anchorage structure system cable, an isolation and anti-wear device 3, a restraint shock absorbing device 4 and a foundation conversion bracket assembly 5;

[0068] The steel strand cable 2 is a combined anchoring structure system, which is composed of a multi-strand steel strand cable body 21, an upper end anchor assembly 1 and a tension end anchor assembly 6, and the upper end anchor assembly 1 is an integral anchor Head, tension end anchor assembly 6 is a single loose cable clamping and anchoring structure;

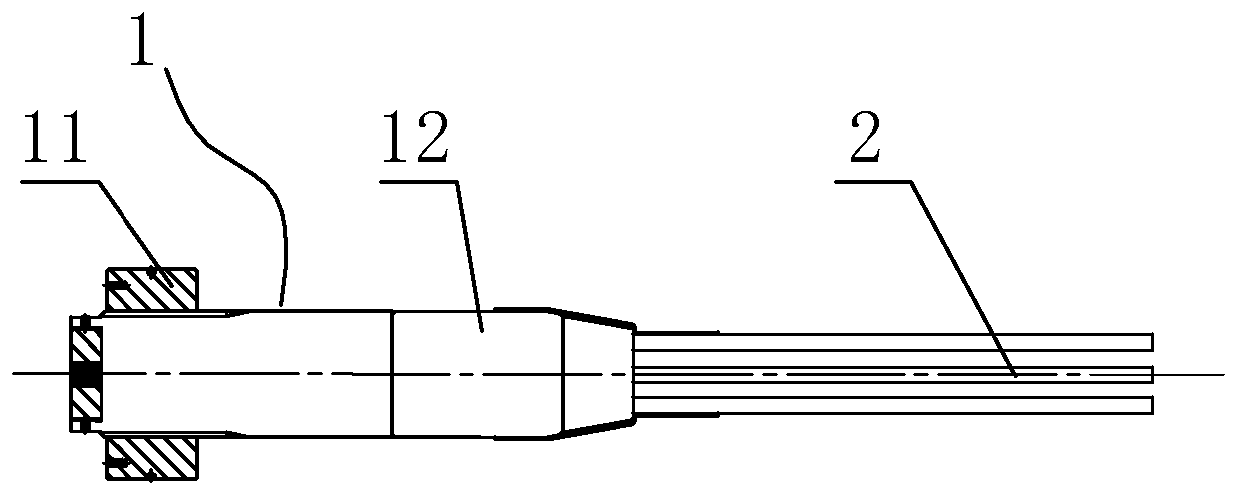

[0069] The upper end anchor assembly 1 includes a nut 11 and an extruded anchor head 12, and the extruded anchor head has external threads (see figure 2 );

[0070] The tension end anchor assembly 6 includes a sealing cylinder 61, an anchor plate 62, a clip 63 and a ...

Embodiment 2

[0077] A method for manufacturing and installing a steel strand external stay cable structure system for a wind tower, which is a method for producing and installing a steel strand external stay cable structure system for a wind tower described in Embodiment 1, and it includes the following steps:

[0078] A. Make the finished steel strand cable 2 whose upper end anchorage component 1 is an integral extruded anchor head:

[0079] A1. Making the integral extruded anchor head:

[0080] According to the designed cable length, the steel strand body is tailored, the steel strand body 21 and the extruded anchor head 12 are extruded and wrapped by special extrusion equipment, and after the upper anchor assembly 1 is manufactured, the anchor head is threaded. (Such as figure 2 shown);

[0081] A2, carry out hypertension to steel strand;

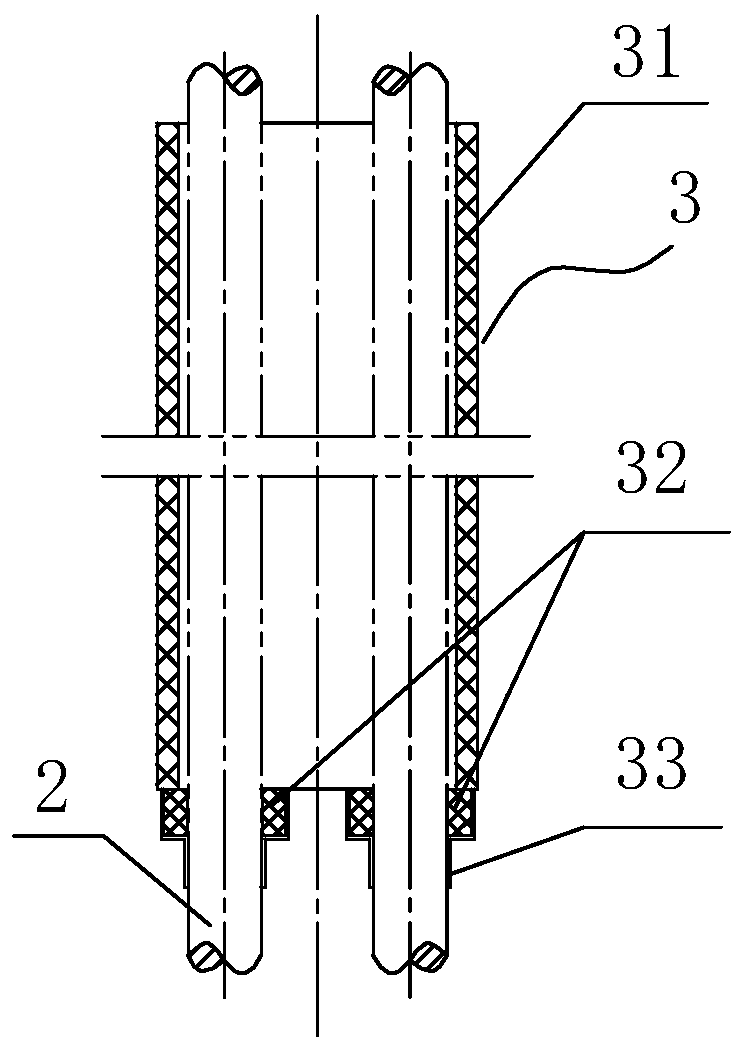

[0082] A3. Install the isolation and anti-wear device:

[0083] After stretching, wear-resistant sleeve 31, spacer sleeve 32, and heat shrinkabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com