Computational lithography modeling method and device

A technology of computational lithography and modeling methods, which is applied in the field of computational lithography modeling methods and devices, and can solve the problems that the accuracy of computational lithography models cannot meet the lithography process, and the accuracy of optimization results cannot be guaranteed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0082] In order to improve the accuracy of the computational lithography model, the present application discloses a computational lithography modeling method and device through the following embodiments.

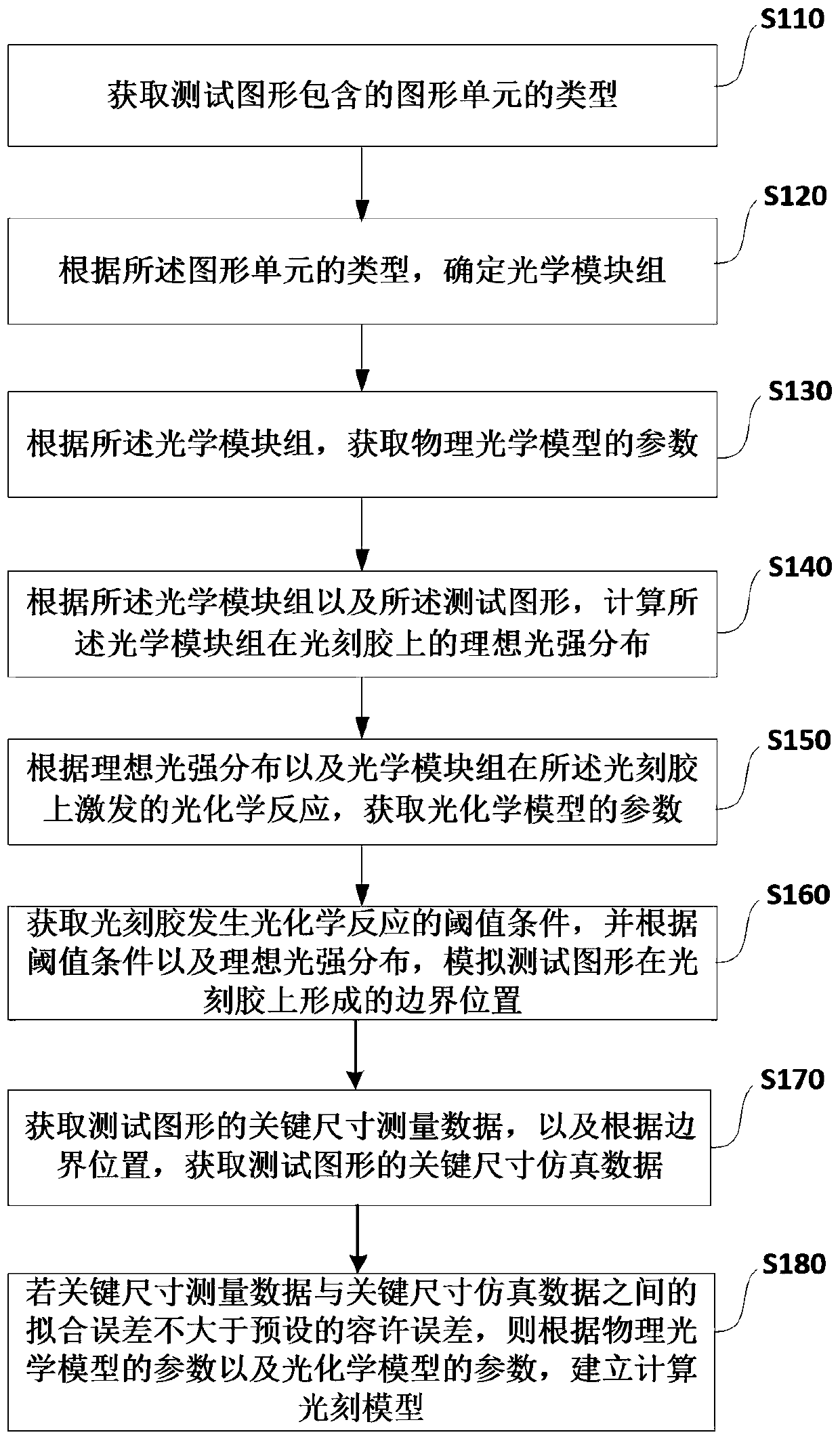

[0083] The first embodiment of the present application discloses a computational lithography modeling method, see figure 1 As shown in the workflow diagram, the method includes:

[0084] Step S110, acquiring the type of pattern units included in the test pattern, wherein the test pattern refers to a reticle pattern used for testing.

[0085] In step S120, an optical module group is determined according to the type of the graphics unit, wherein the optical module group is composed of a plurality of optical modules.

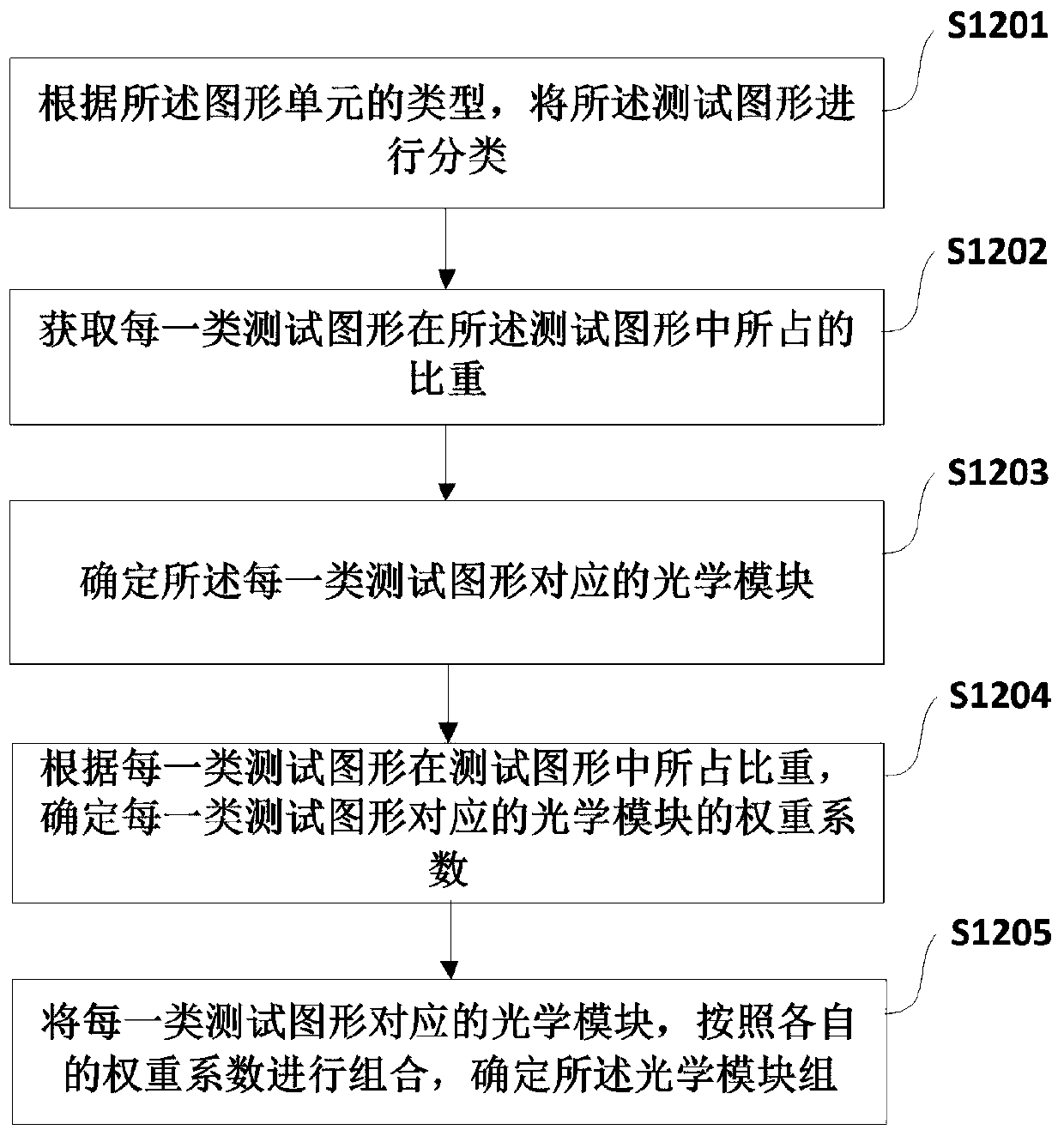

[0086] see figure 2 as shown, figure 2 According to the type of the graphics unit disclosed in the embodiment of the present application, a schematic diagram of the workflow for determining the optical module group includes:

[0087] Step S1201, classify th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com