Piezoelectric type and capacitive type combined MEMS microphone

A capacitive and combined technology, applied in piezoelectric/electrostrictive transducer microphones, microelectronic microstructure devices, electrical components, etc., can solve complex manufacturing processes, capacitive MEMS microphone performance bottlenecks, and reliability changes. Poor problems, to achieve the effect of improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

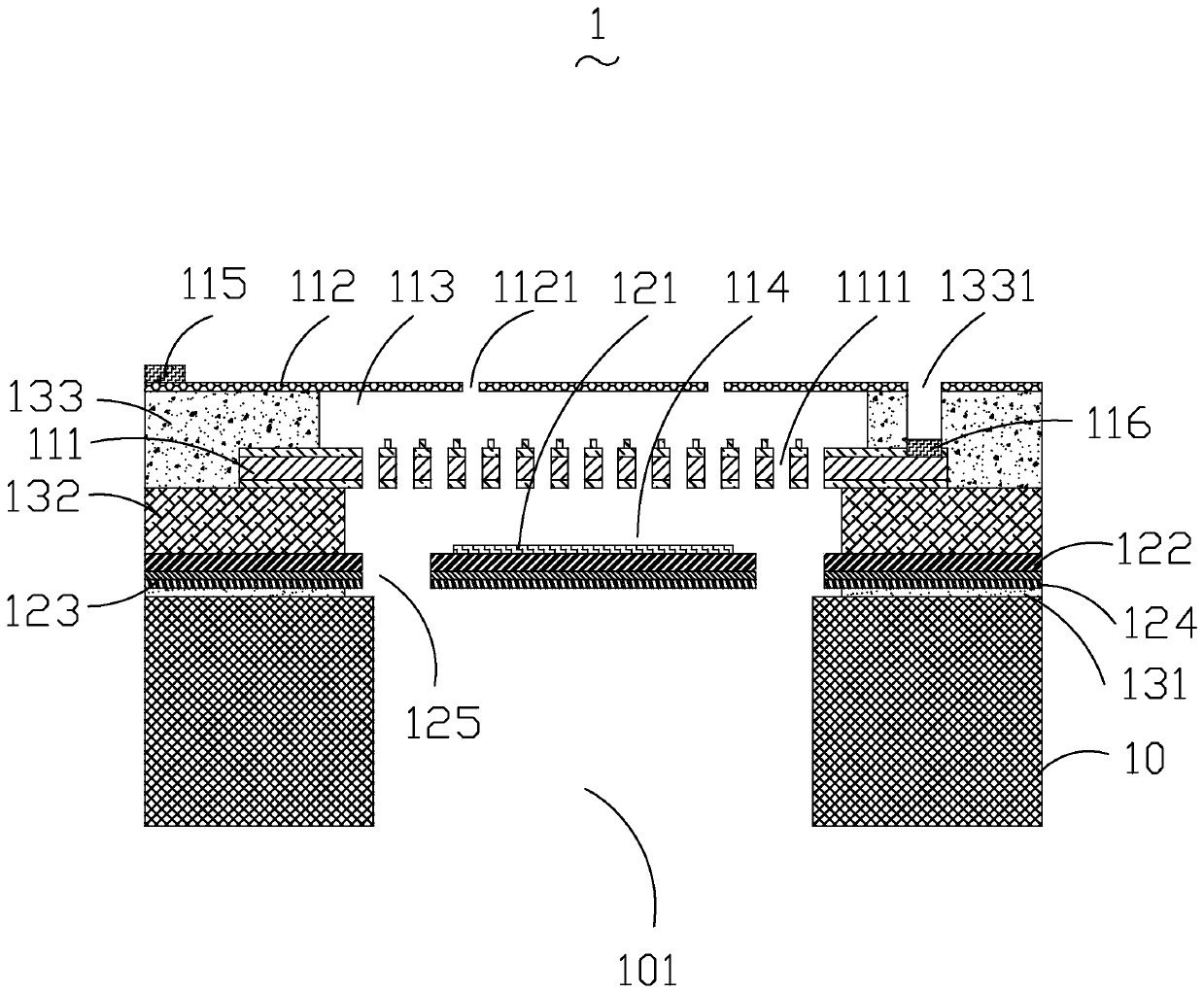

[0035] see figure 1 and figure 2 , the present embodiment provides a piezoelectric and capacitive MEMS microphone 1, including a base 10 and a capacitive system disposed on the base 10 and insulated and connected to the base 10, between the capacitive system and the base 10 A piezoelectric film structure 12 is also provided, a first insulating layer 131 is provided between the piezoelectric film structure 12 and the base, and a second insulating layer 132 is provided between the capacitor system and the piezoelectric film structure 12 .

[0036] The base 10 is made of semiconductor material and has a back cavity 101 , an upper surface and a lower surface opposite to the upper surface. The back cavity 101 runs through the upper surface and the lower surface. The back cavity 101 can be formed by bulk silicon micromachining or etching. The capacitive system is arranged on the piezoelectric film structure 12 through the second insulating layer 132, and the capacitive system incl...

Embodiment 2

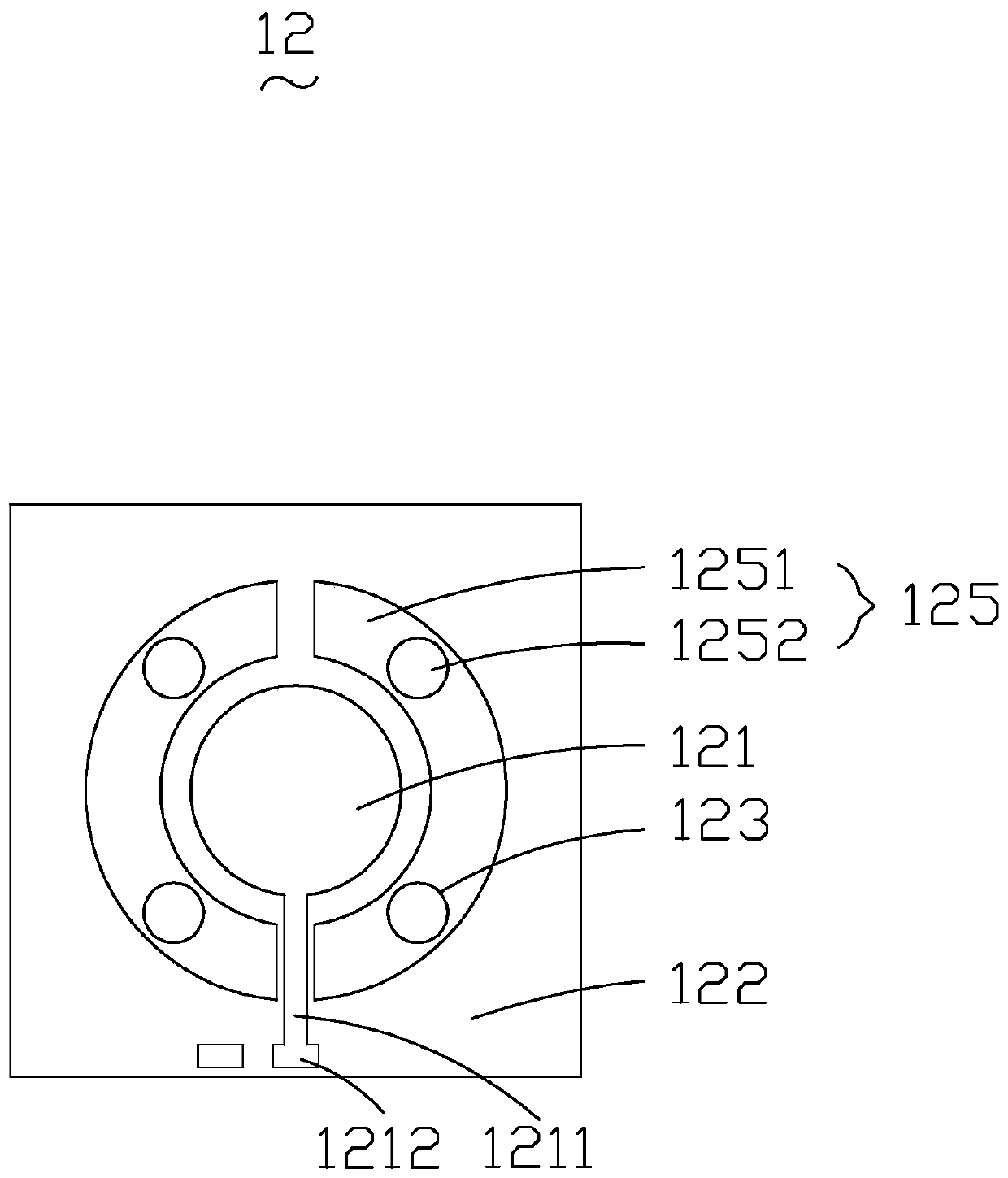

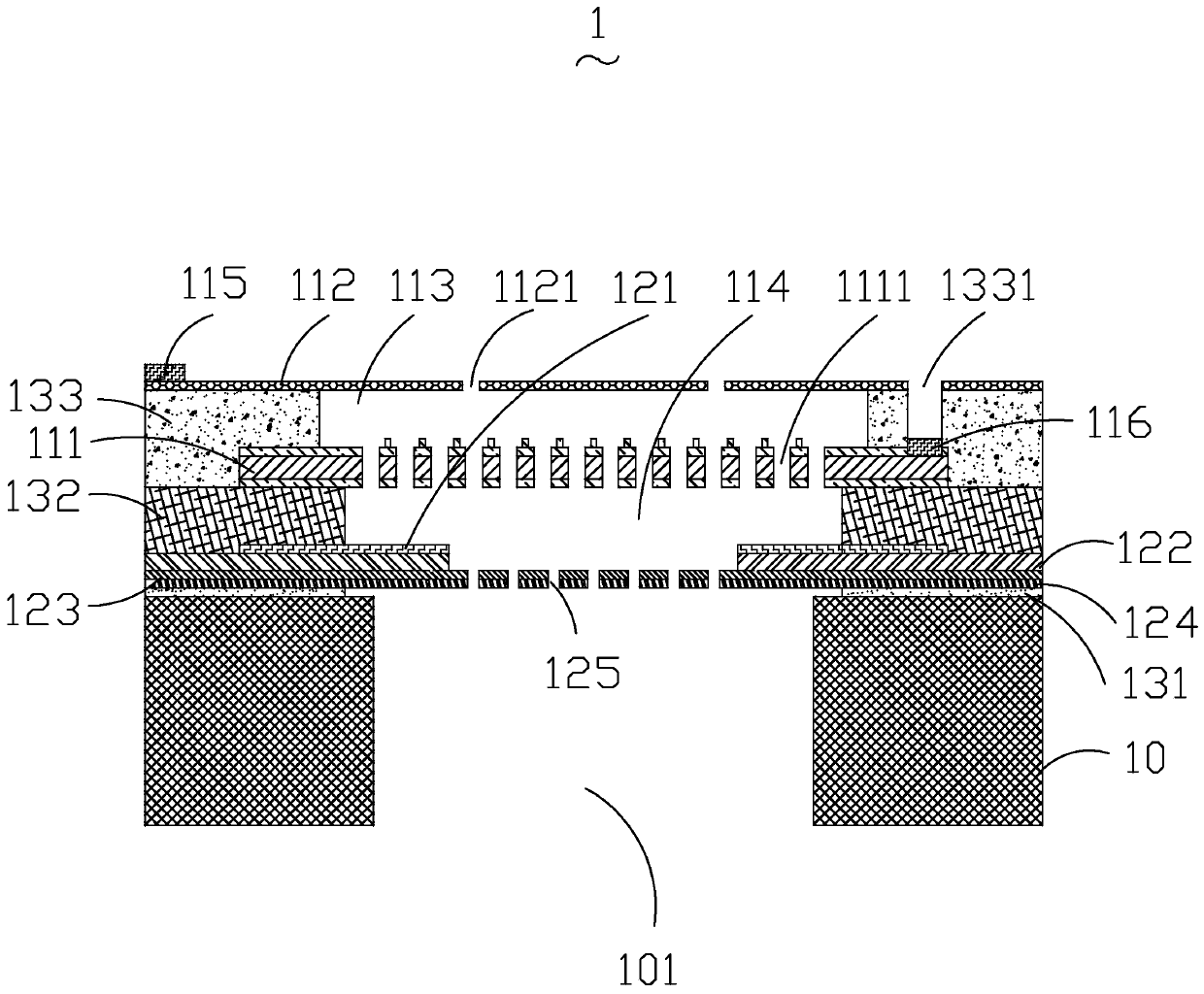

[0047] see image 3 and Figure 4 The difference between this embodiment and Embodiment 1 lies in the piezoelectric membrane structure 12. The piezoelectric membrane structure 12 of this embodiment is an edge-curved structure, which includes a first electrode sheet 121, a piezoelectric film laminated in sequence sheet 122, the second electrode sheet 123, the first electrode line 1211 and the first electrode terminal 1212, the center of the first electrode sheet 121, the center of the piezoelectric film 122 and the center of the second electrode sheet 123 are all on the same vertical line Above, the first electrode sheet 121 is compounded on the side of the piezoelectric film 122 facing the back plate 111, the first electrode sheet 121 is connected to the first electrode terminal 1212 through the first electrode wire 1211, and the second electrode 123 is compounded on the piezoelectric film One side of the sheet 122 facing the base 10, the two ends of the piezoelectric film 12...

Embodiment 3

[0052] see Figure 5 and Figure 6 The difference between this embodiment and Embodiment 1 lies in the piezoelectric diaphragm structure 12. The piezoelectric diaphragm structure 12 in this embodiment is a four-cantilever beam structure, which includes a first electrode sheet 121, a pressing Electric diaphragm 122, second electrode sheet 123, first electrode wire 1211 and first electrode terminal 1212, the center of first electrode sheet 121, the center of piezoelectric diaphragm 122 and the center of second electrode sheet 123 are all on the same vertical line. On the straight line, the first electrode sheet 121 is compounded on the side of the piezoelectric film 122 facing the back plate 111, the first electrode sheet 121 is connected to the first electrode terminal 1212 through the first electrode wire 1211, and the second electrode 123 is compounded on the piezoelectric film 122. On the side of the electric diaphragm 122 facing the base 10, the piezoelectric diaphragm 122...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com