Preparation method of anti-stripping rubber asphalt mixture

A technology for rubberized asphalt and mixture, which is applied in the field of preparation of anti-stripping rubberized asphalt mixture, can solve the problems of poor adhesion between acid aggregate and asphalt, improve the ability to resist water damage, solve early damage, and change surface properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

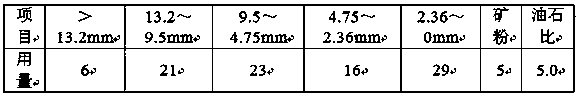

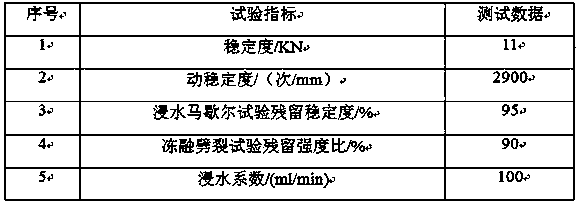

[0020] Example 1 Preparation of 1# anti-peeling rubber asphalt mixture

[0021] In the first step, put 100 parts of base asphalt, 4 parts of softener tall oil, and 0.8 parts of activator (a compound of alkylphenol disulfide and xylene disulfide at a mass ratio of 1:2) into the modified Heat in the asphalt reaction tank, when the temperature rises to 120°C, stir at constant temperature for 5 minutes, add 20 parts of rubber powder and start to raise the temperature step by step: when the temperature rises to 150°C, 4.5 parts, 0.9 parts of activator (alkylphenol disulfide and Xylene disulfide compounded with a mass ratio of 1:2) were put into the modified asphalt reaction tank and heated together. When the temperature rose to 120°C, the temperature was stirred for 5 minutes, and 20 parts of rubber powder was added to start the temperature rise step by step: when When the temperature rises to 150°C, stir at a constant temperature for 10 minutes; when the temperature continues to r...

Embodiment 2

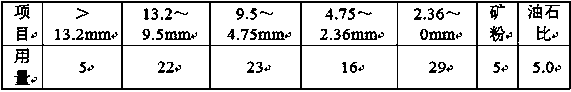

[0030] Example 2 Preparation of 2# anti-peeling rubber asphalt mixture

[0031] In the first step, put 100 parts of base asphalt, 5 parts of softener tall oil, and 1.2 parts of activator (a compound of alkylphenol disulfide and xylene disulfide at a mass ratio of 1:2) into the modified Heat in the asphalt reaction tank, when the temperature rises to 120°C, stir at a constant temperature for 5 minutes, add 25 parts of rubber powder and start to raise the temperature step by step: when the temperature rises to 150°C, stir at a constant temperature for 10 minutes; when the temperature continues to rise to 180°C, stir at a constant temperature for 10 minutes ;When the temperature rises to 200°C, stir and react at this temperature for 30 minutes; then lower the temperature to 180°C, and store the prepared rubber asphalt for later use;

[0032] In the second step, add 5 parts of deionized water and 2.5 parts of absolute ethanol into the beaker to prepare an ethanol solution, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com