Refractory thermal insulation material and preparing method thereof

A technology for fire prevention and heat preservation and raw materials, which is applied to clay products, ceramic products, and other household appliances, etc., can solve the problems of limiting the application range of heat preservation materials, and the strength and flame retardant effect of building heat preservation materials are difficult to meet high standards, and achieve significant technical effects. and economic advantages, good thermal insulation function, the effect of improving compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A fire-proof and heat-preserving material, said fire-proof and heat-preserving material is formed by adding water and foaming the following components in parts by weight: 10 parts of fruit shell powder, 10 parts of feldspar, 50 parts of shale, 10 parts of sandstone, limestone 1 part, 5 parts of magnesite, 5 parts of modified nano-silicon dioxide, and an appropriate amount of water; the surface of the fireproof and thermal insulation material is also coated with a flame retardant. The amount of water is 65% of the total weight of the modified nano-silica, feldspar, shale, sandstone, limestone and magnesite dry material.

[0035] The modified nano silicon dioxide is prepared by the following method:

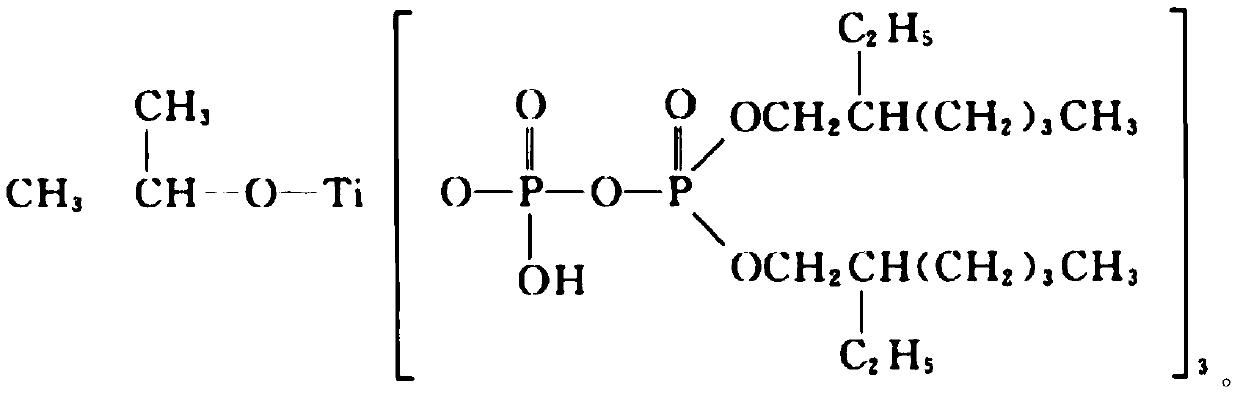

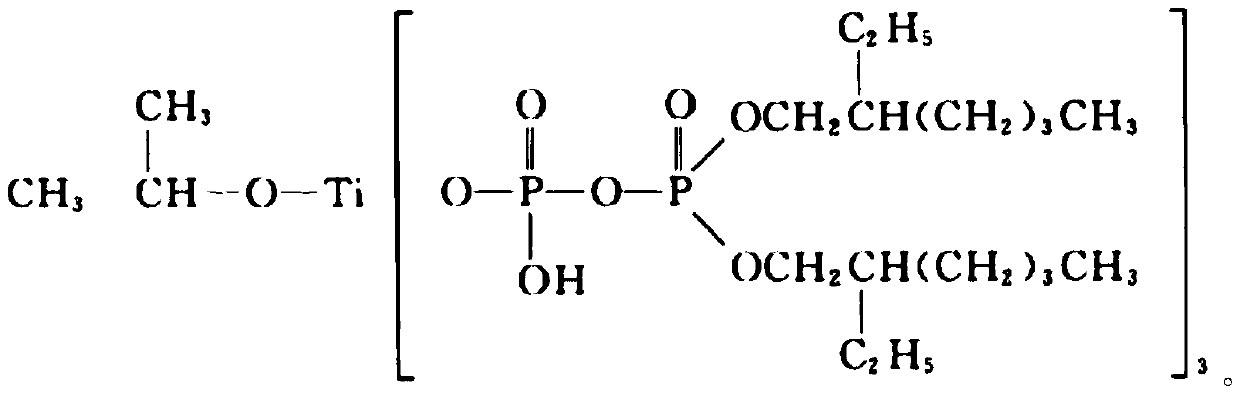

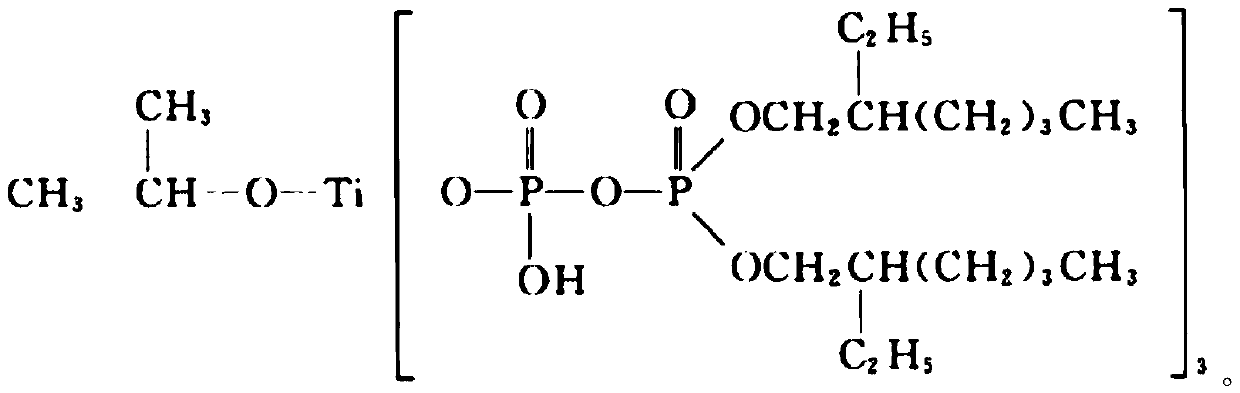

[0036] S1 After mixing the modifying agent and absolute ethanol, pour nano-silica into it, stir it ultrasonically, and leave it to stand after the reaction to obtain a nano-silica gel solution; the amount of the modifying agent is nano-silica 10wt%; the particle size range ...

Embodiment 2

[0052] A fire-proof and heat-preserving material, said fire-proof and heat-preserving material is formed by adding water and foaming the following components in parts by weight: 13 parts of fruit shell powder, 12 parts of feldspar, 55 parts of shale, 12 parts of sandstone, limestone 2 parts, 7 parts of magnesite, 6 parts of modified nano-silicon dioxide, and an appropriate amount of water; the surface of the fireproof and thermal insulation material is also coated with a flame retardant. The amount of water is 66% of the total weight of the modified nano silicon dioxide, feldspar, shale, sandstone, limestone and magnesite dry material.

[0053] The modified nano silicon dioxide is prepared by the following method:

[0054] S1 After mixing the modifying agent and absolute ethanol, pour nano-silica into it, stir it ultrasonically, and leave it to stand after the reaction to obtain a nano-silica gel solution; the amount of the modifying agent is nano-silica 10wt%; the particle s...

Embodiment 3

[0070] A fire-proof and heat-preserving material, said fire-proof and heat-preserving material is formed by adding water and foaming the following components in parts by weight: 16 parts of fruit shell powder, 15 parts of feldspar, 60 parts of shale, 13 parts of sandstone, limestone 3 parts, 8 parts of magnesite, 7 parts of modified nano-silicon dioxide, and an appropriate amount of water; the surface of the fireproof and thermal insulation material is also coated with a flame retardant. The amount of water is 68% of the total weight of the modified nano silicon dioxide, feldspar, shale, sandstone, limestone and magnesite dry material.

[0071] Preferably, the modified nano-silica is prepared by the following method:

[0072] S1 After mixing the modifying agent and absolute ethanol, pour nano-silica into it, stir it ultrasonically, and leave it to stand after the reaction to obtain a nano-silica gel solution; the amount of the modifying agent is nano-silica 10wt%; the particl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com