A flexible substrate silver nanowire transparent conductive film and preparation method thereof

A technology of transparent conductive films and silver nanowires, which is applied in the direction of equipment for manufacturing conductive/semiconductive layers, cable/conductor manufacturing, conductive layers on insulating carriers, etc., can solve the problem of transparent conductive flexible silver nanowires and win robustness Poor performance, increasing the driving voltage of the electrochromic device, weak physical and chemical interactions, etc., to achieve the effect of reducing the driving voltage of the electrochromic device, easy operation, poor robustness and strong performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

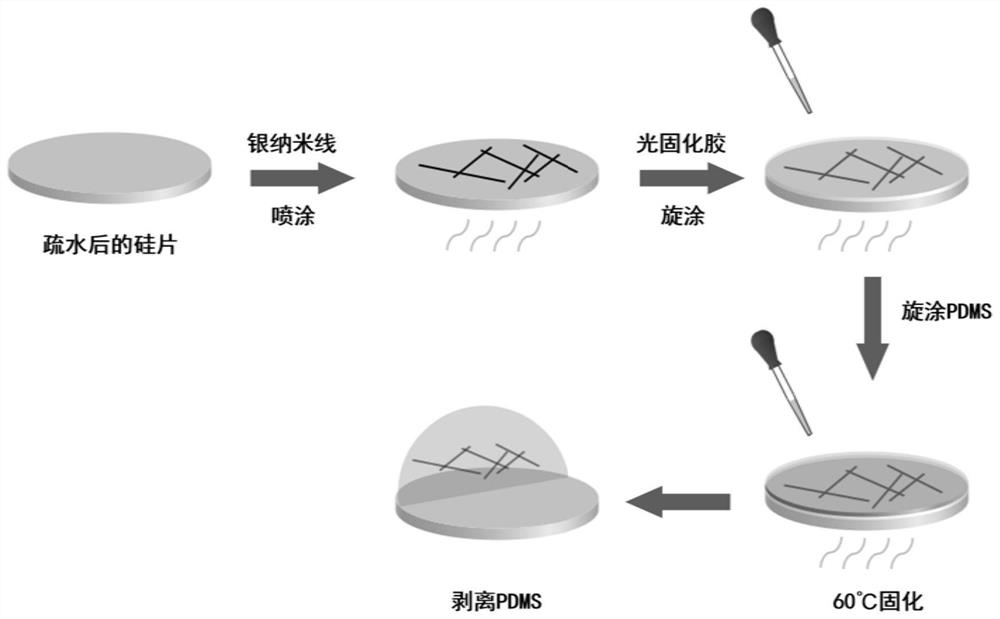

[0030] see figure 1 , a method for preparing a transparent conductive film of silver nanowires on a flexible substrate according to an embodiment of the present invention is a method for preparing a transparent conductive film of silver nanowires on a flexible substrate with robust performance, comprising the following steps:

[0031] (1) Preparation of silver nanowire transparent conductive film:

[0032] Spray silver nanowire ethanol dispersion on a clean and flat rigid substrate to obtain a silver nanowire transparent conductive film; place it on a heating plate at 80°C for 10-15 minutes and dry it for 10-15 minutes; perform curing treatment in an oven at a curing temperature of 180°C- 220°C, the time is 15min to 20min.

[0033] Specifically, the rigid substrate for cleaning is silicon wafer, PET or cover glass after hydrophobic treatment.

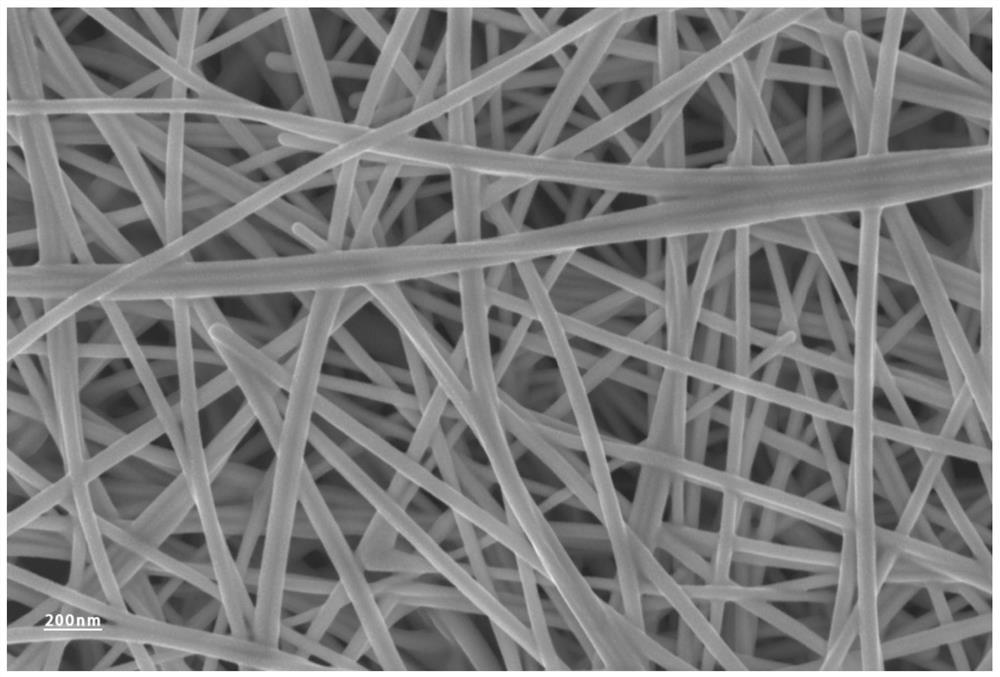

[0034] Preferably, the aspect ratio of the silver nanowires is 800-1000, and the diameter of the silver nanowires is preferably less...

Embodiment 1

[0049] A method for preparing a flexible substrate silver nanowire transparent conductive film according to an embodiment of the present invention comprises the following steps:

[0050] (1) Preparation of silver nanowire transparent conductive film:

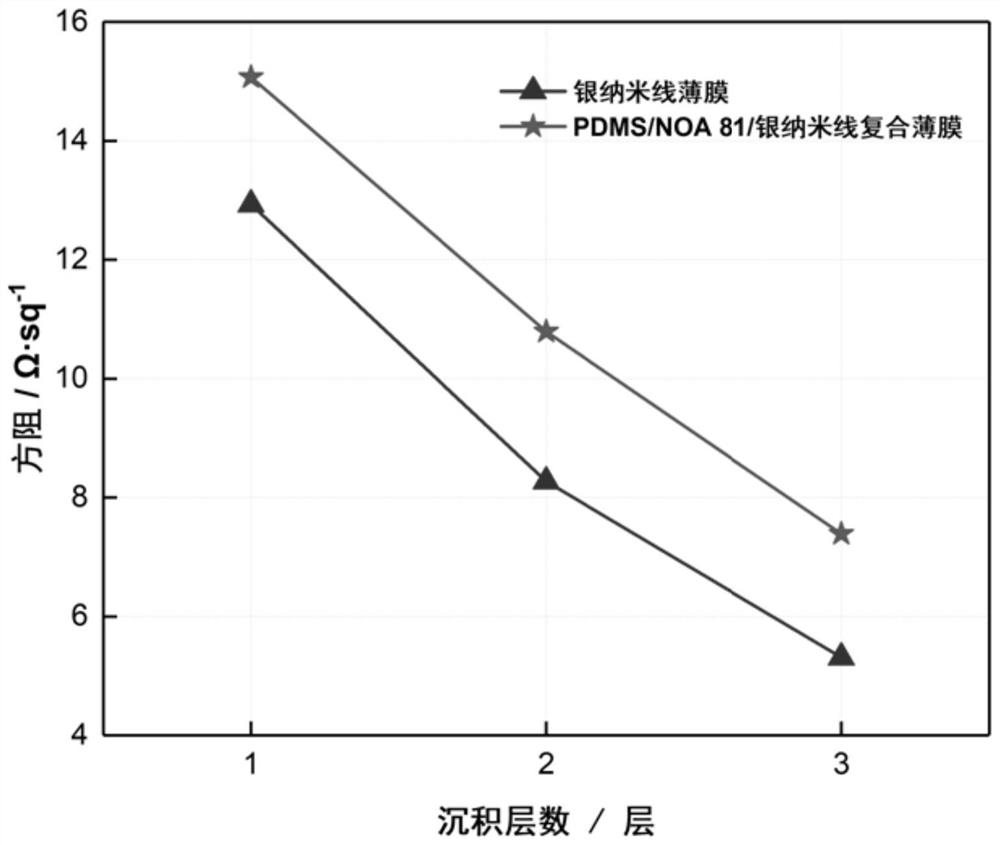

[0051] Add the silver nanowire ethanol dispersion into the airbrush, the diameter of the airbrush is 0.3mm, spray evenly at a spraying speed of 1cm / s, deposit a layer of silver nanowire network substrate with a certain arrangement density, and then coat the silver nanowire The silicon substrate of the wire transparent conductive film is placed on a heating plate at 80°C for 10 minutes, and then cured at 180°C in an oven for 15 minutes to obtain a transparent conductive film of silver nanowires. The transmittance at the wavelength is 91.7%, and the square resistance measured by four probes is 12.93Ω·sq -1 .

[0052] (2) Preparation of photocurable adhesive / silver nanowire composite transparent conductive film:

[0053] Add pho...

Embodiment 2

[0058] A method for preparing a flexible substrate silver nanowire transparent conductive film according to an embodiment of the present invention comprises the following steps:

[0059] (1) Preparation of silver nanowire transparent conductive film:

[0060] Add the silver nanowire ethanol dispersion into the airbrush, the diameter of the airbrush is 0.3mm, spray evenly at a spraying speed of 1cm / s, deposit two layers of silver nanowire network substrates with a certain arrangement density, and then coat the silver nanowire The silicon substrate of the wire transparent conductive film is placed on a heating plate at 80°C for 10 minutes, and then cured at 200°C in an oven for 15 minutes to obtain a silver nanowire transparent conductive film. The transmittance at the wavelength is 87.3%, and the square resistance measured by four probes is 8.27Ω sq. -1 , due to the increase in the number of depositions of silver nanowires, the network of silver nanowires increases, so the tra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com