Mixed metal powder for imbricated conductive adhesive and preparation method of mixed metal powder for imbricated conductive adhesive

A technology of mixing metal and conductive adhesive, which is applied in the field of metal powder processing, can solve the problems of high price of pure silver shingled conductive adhesive and easy oxidation of silver-clad copper shingled conductive adhesive, and achieve good conductivity, not easy to oxidize, and reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

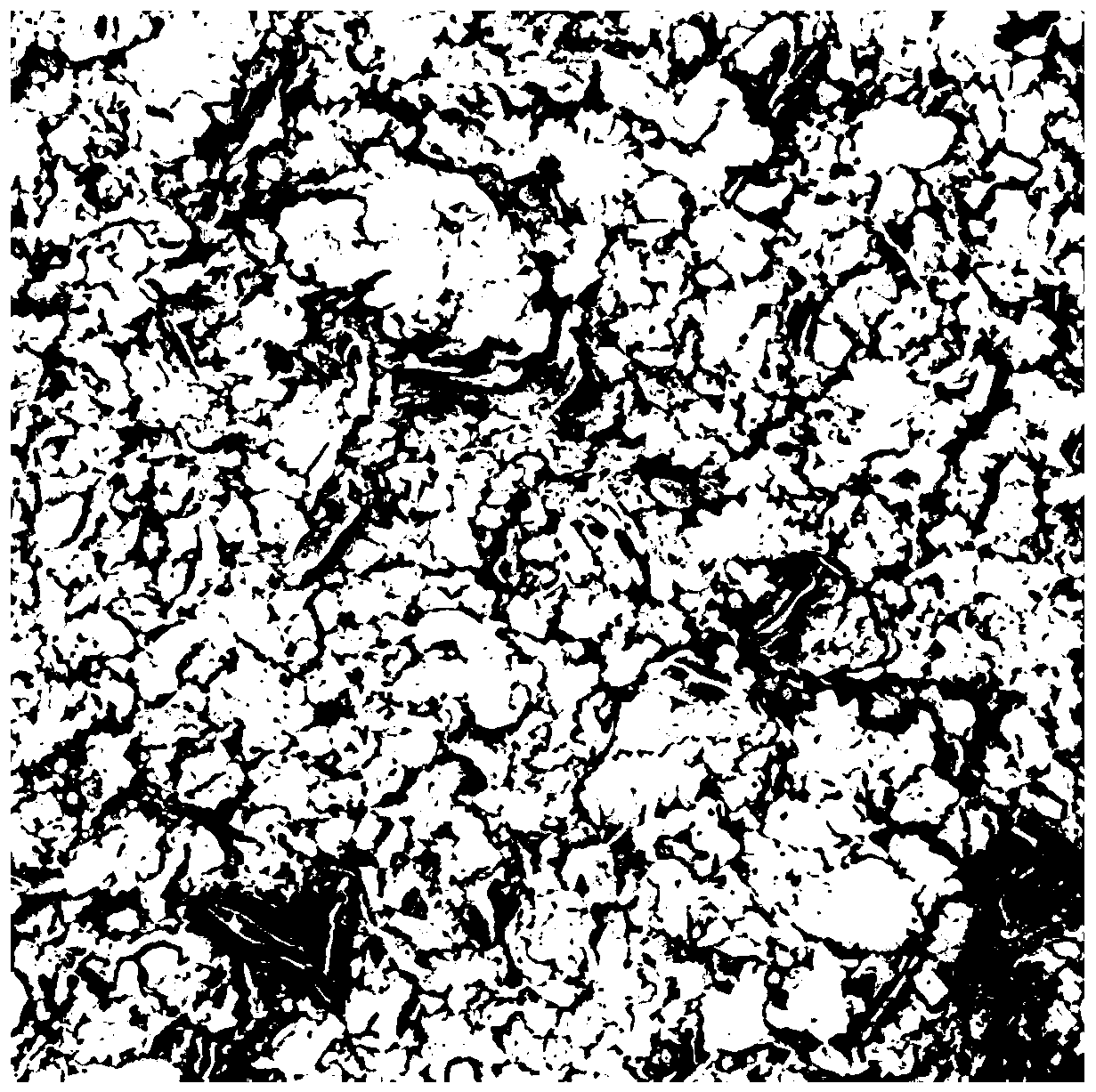

Image

Examples

preparation example Construction

[0019] The present invention also provides a method for preparing mixed metal powder for shingled conductive adhesive, comprising the following steps:

[0020] S1: by weight percentage (6~85): (10~90): (0.1~10) Weigh flake silver powder, metal hydride and zinc sulfate, and mix them evenly to obtain a metal mixture; The metal powder has low preparation cost and excellent electrical conductivity, and can better overcome the problems of silver migration and oxidation caused by the use of pure silver powder in the prior art.

[0021] Preferably, the purity of the flake silver powder, metal hydride and zinc sulfate are all ≥99%, and the high-purity raw material can ensure that the final product has a low impurity content, so that the performance is more excellent.

[0022] Preferably, the average particle size of the flake silver powder is 0.3-10 μm, and the particle size of the silver powder is too large, which will make it difficult to chemically deposit or coat the surface of me...

Embodiment 1

[0033] This embodiment provides a mixed metal powder for shingled conductive adhesive, the mixed metal powder is composed of silver powder, metal hydride and zinc sulfate, and the silver powder content is 74.89%; the average particle size of the mixed metal powder is 5 μm .

[0034] The present embodiment also provides a method for preparing mixed metal powder for shingled conductive adhesive, comprising the following steps:

[0035] S1: take by weighing 12 kilograms of silver powder, 3 kilograms of bismuth hydride and 1 kilogram of zinc sulfate, mix well to obtain a metal mixture;

[0036] S2: add 8 kilograms of terpineol to the metal mixture, then add 0.5 kilograms of resin L (Hunan Unico Chemical Technology Co., Ltd.) and 16 kilograms of zirconia beads (particle size is 1mm), carry out sand grinding 30min, obtain the mixture liquid;

[0037] S3: filter the mixed liquid and dry at 60° C. for 30 minutes to obtain mixed metal powder for shingled conductive adhesive.

Embodiment 2

[0039]This embodiment provides a mixed metal powder for shingled conductive adhesive, the mixed metal powder is composed of silver powder, metal hydride and zinc sulfate, and the silver powder content is 83.81%; the average particle size of the mixed metal powder is 6 μm .

[0040] The present embodiment also provides a method for preparing mixed metal powder for shingled conductive adhesive, comprising the following steps:

[0041] S1: take by weighing 13 kilograms of silver powder, 2 kilograms of titanium hydride and 0.5 kilograms of zinc sulfate, mix well to obtain a metal mixture;

[0042] S2: add 15 kilograms of terpineol to the metal mixture, then add 0.2 kilograms of resin L (Hunan Unico Chemical Technology Co., Ltd.), 0.55 kilograms of butyl butyrate and 50 kilograms of zirconia beads (0.6mm), and carry out sand grinding 5min to obtain the mixed material liquid;

[0043] S3: filter the mixed liquid and dry at 70° C. for 20 min to obtain mixed metal powder for shingle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com