Ti-Ti2AlC/TiAl3 laminated composite material with cylindrical alternately-stacked structure and preparation method thereof

A composite material, stacking structure technology, applied in the Ti-Ti2AlC/TiAl3 laminated composite material and its preparation, the field of preparation materials, can solve the problem that blasting is prone to large cracks, the anti-penetration ability of laminated composite armor is limited, and it is difficult to deal with and other problems, to achieve the effect of dissipating the fracture energy, improving the hardness of the micro-zone, and reducing the degree of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

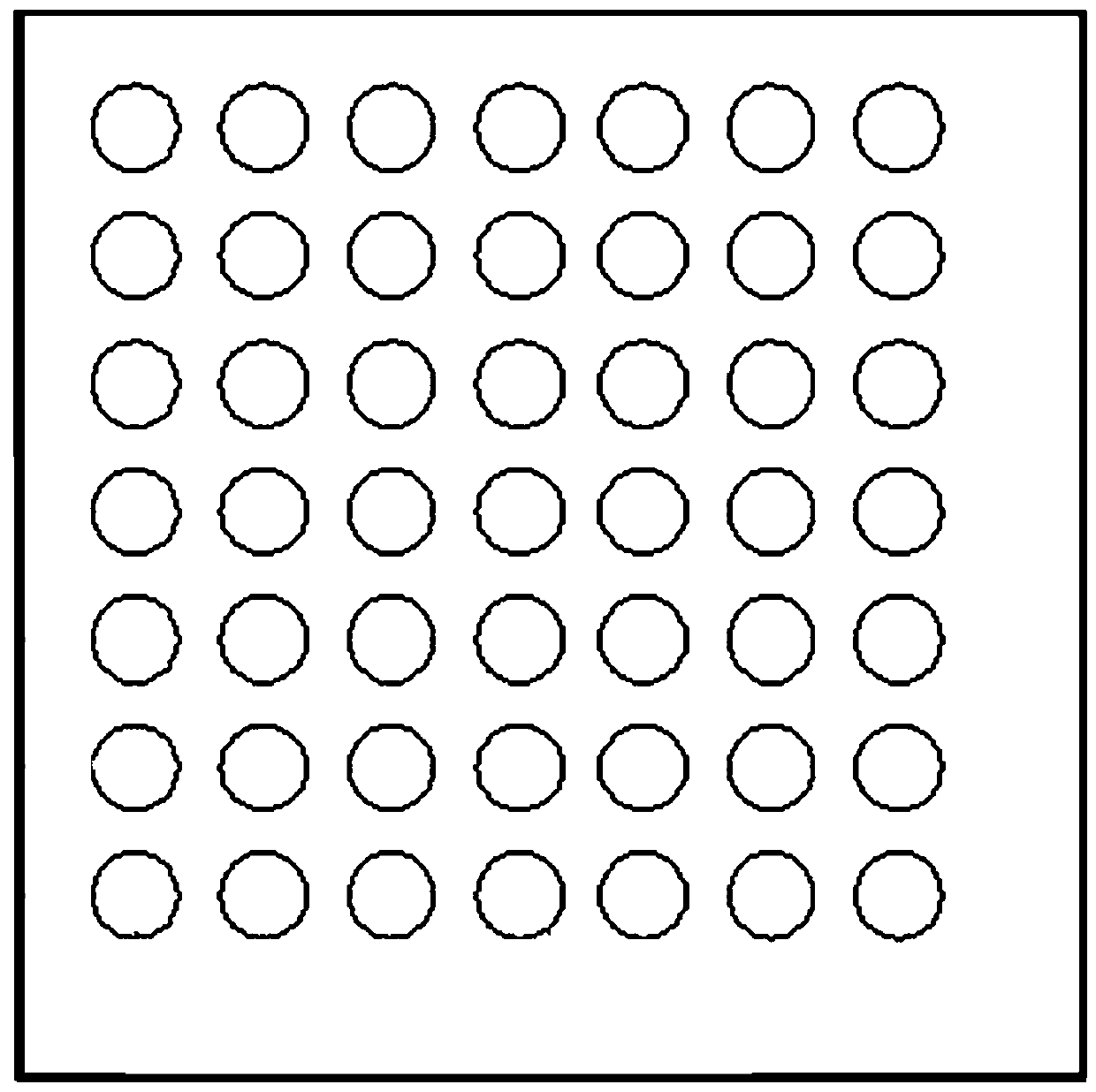

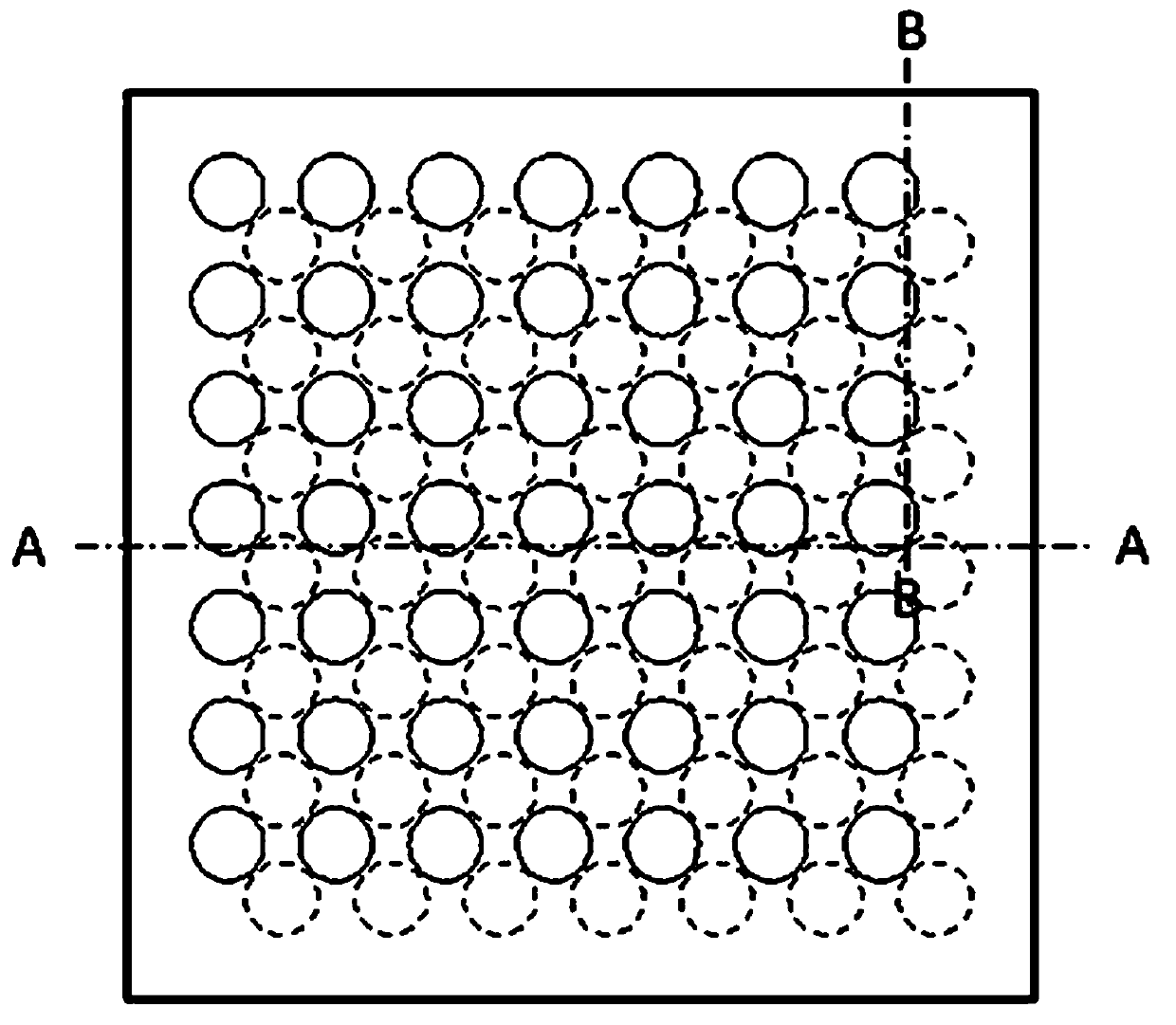

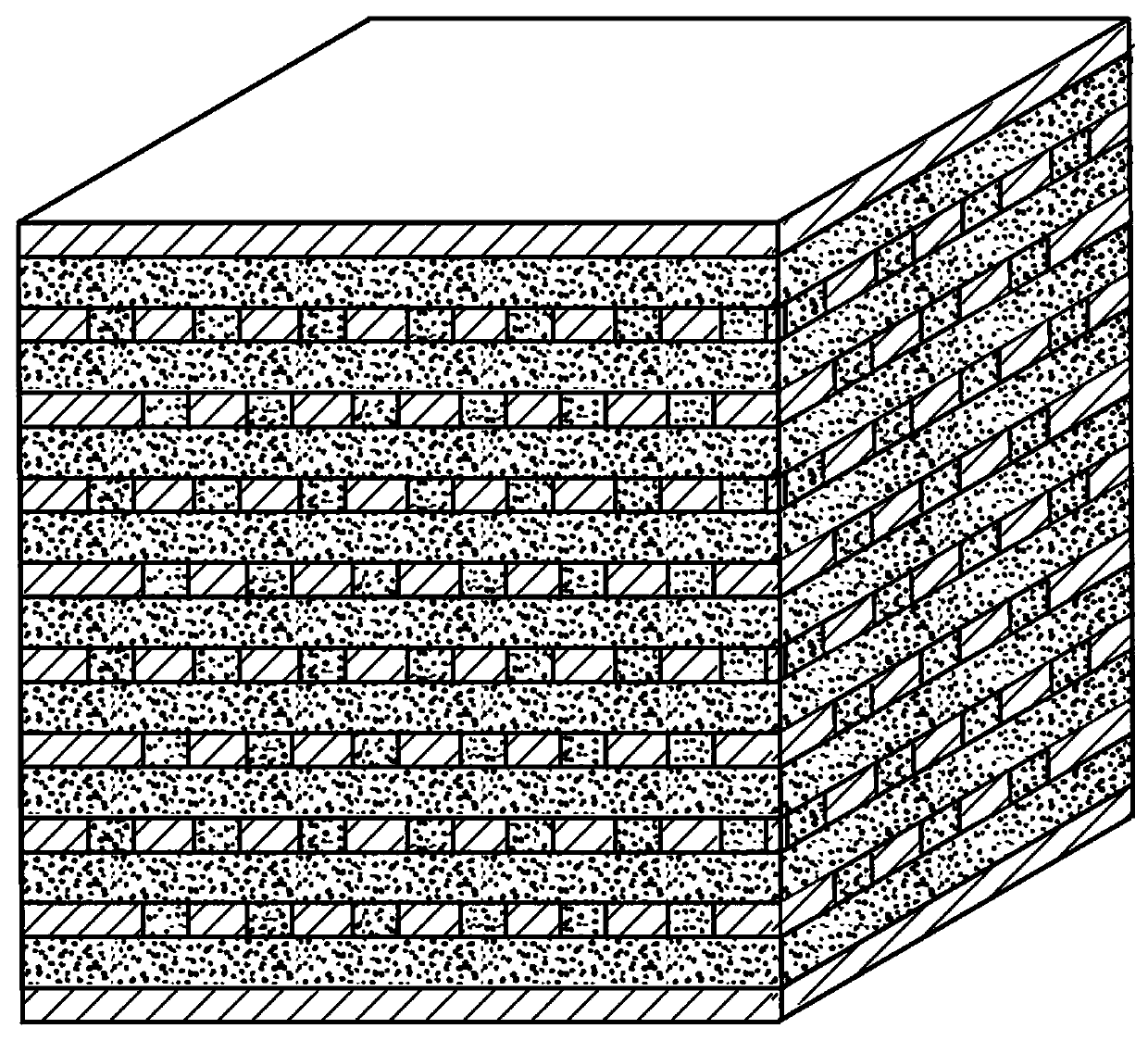

[0025] Example 1: Ti-Ti with a cylindrical staggered stacked structure 2 AlC / TiAl 3 A method for preparing a laminated composite material, comprising the steps of:

[0026] , Preparation of uniformly mixed composite powder: Aluminum powder with an average particle size of less than 30 μm and a purity of 99.7% and Ti with an average particle size of less than 70 μm and a purity of 96% 2 AlC powder is put into a ball mill with a molar ratio of 5:1 for ball milling. Set the ball milling ratio to 10:1, the rotational speed to 300r / min, and the ball milling time to be more than 8 hours. Add alcohol as a ball milling aid during the milling process, and the milling is complete. Then put the ball mill into the dryer to dry for 2 hours, and finally sieve the dried composite powder with a Retsch AS200 mechanical vibrating sieve, and the particle size of the powder is 200 mesh;

[0027] 1. Prepare TC4 foil layer: cut all TC4 foil layers with a thickness of 0.15mm into 100×100mm foi...

Embodiment 2

[0036] Example 2: Ti-Ti with a cylindrical staggered stacked structure 2 AlC / TiAl 3 A method for preparing a laminated composite material, comprising the steps of:

[0037] , Preparation of uniformly mixed composite powder: Aluminum powder with an average particle size of less than 30 μm and a purity of 99.9% and Ti with an average particle size of less than 70 μm and a purity of 98.5% 2 AlC powder is put into a ball mill with a molar ratio of 20:1 for ball milling. Set the ball milling ratio to 10:1, the speed to 300r / min, and the ball milling time to be more than 8 hours. Add alcohol as a ball milling aid during the milling process, and the milling is completed. Then put the ball mill into the drying machine to dry for 2 hours, and finally use the RetschAS200 mechanical vibrating sieve to sieve the dried composite powder. The particle size of the composite powder after sieving is 300 mesh;

[0038] 1. Prepare TC4 foil layer: cut all TC4 foil layers with a thickness of ...

Embodiment 3

[0047] Embodiment 3: Ti-Ti of a kind of cylindrical staggered stacking structure 2 AlC / TiAl 3 A method for preparing a laminated composite material, comprising the steps of:

[0048] , Preparation of uniformly mixed composite powder: Aluminum powder with an average particle size of less than 30 μm and a purity of 99.9% and Ti with an average particle size of less than 70 μm and a purity of 98% 2 AlC powder is put into a ball mill with a molar ratio of 10:1 for ball milling. Set the ball milling ratio to 10:1, the speed to 300r / min, and the ball milling time to be more than 8 hours. Add alcohol as a ball milling aid during the milling process, and the milling is completed. Then put the ball mill into the drying machine to dry for 2 hours, and finally use the Retsch AS200 mechanical vibrating sieve to sieve the dried composite powder. The particle size of the composite powder after sieving is 350 mesh;

[0049] 1. Prepare TC4 foil layer: cut all TC4 foil layers with a thic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com