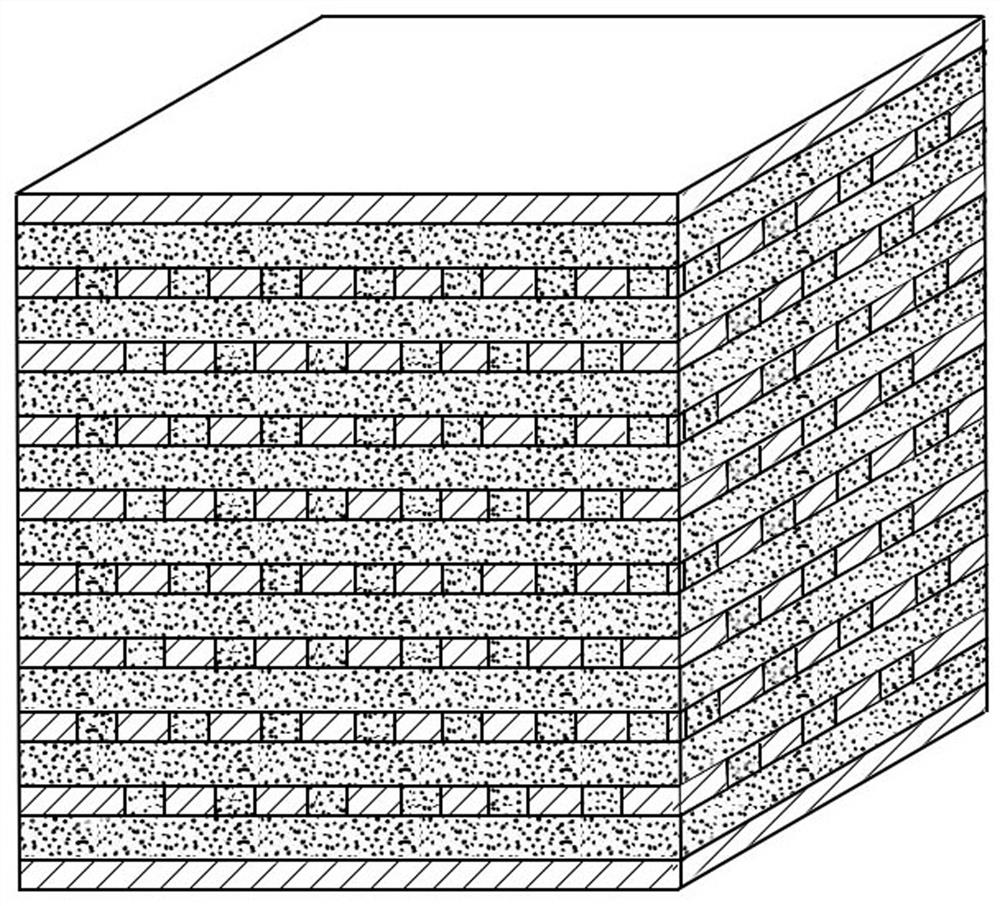

A ti-ti with a cylindrical staggered stack structure 2 alc/tial 3 Laminated composite material and its preparation method

A composite material and stacked structure technology, applied in the field of armor protection, can solve the problems of difficult to deal with, limited anti-penetration ability of laminated composite armor, easy to produce large cracks in blasting, etc. The effect of dissipating fracture energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

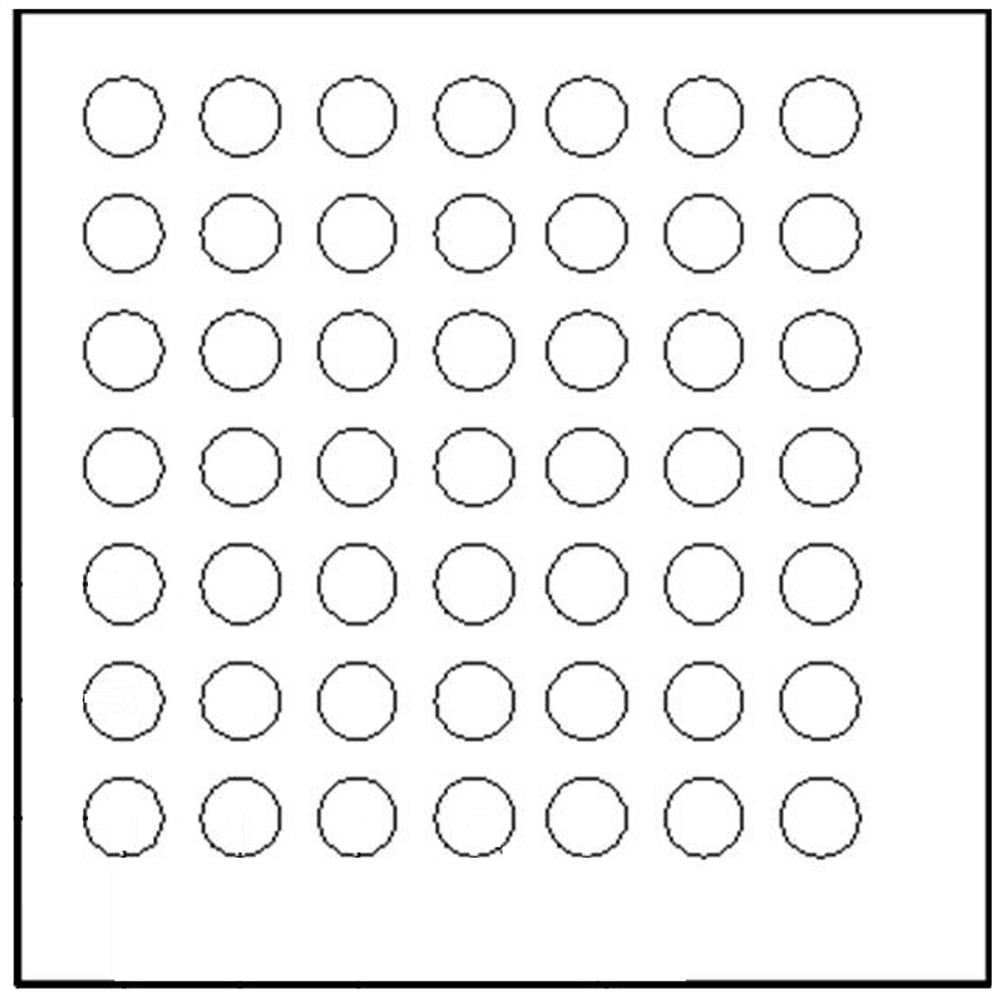

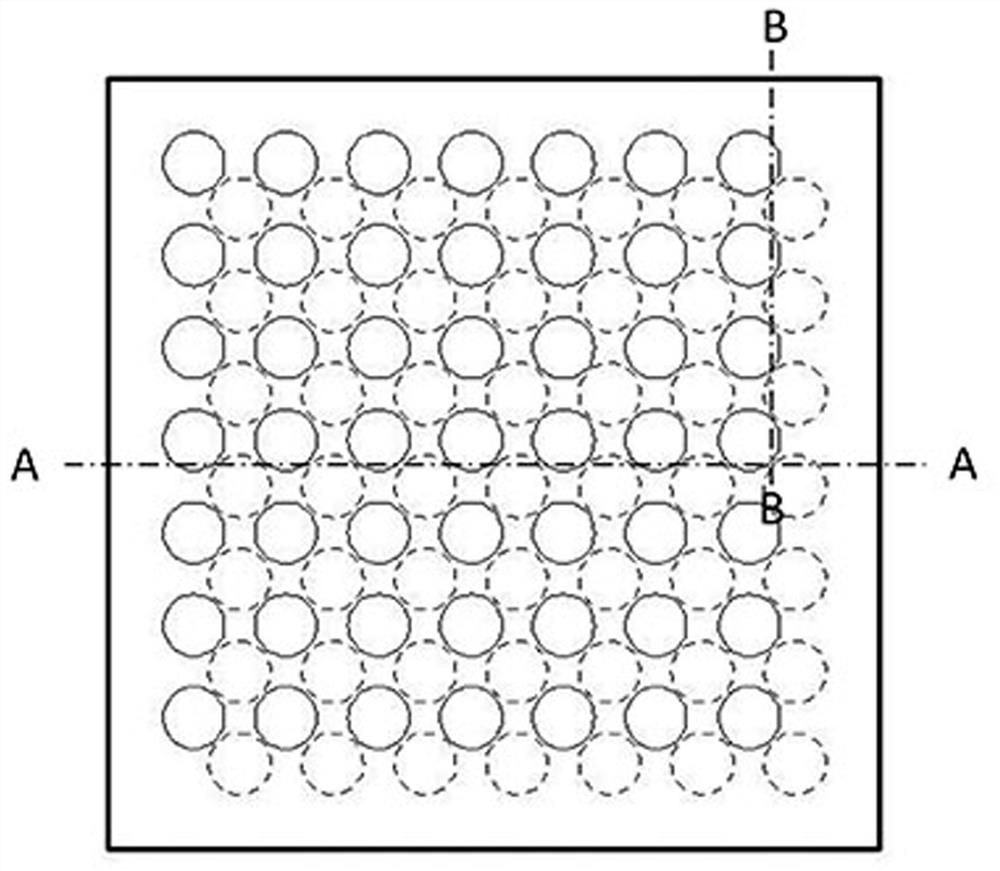

[0025] Example 1: Ti-Ti with a cylindrical staggered stacked structure 2 AlC / TiAl 3 A method for preparing a laminated composite material, comprising the steps of:

[0026] , Preparation of uniformly mixed composite powder: Aluminum powder with an average particle size of less than 30 μm and a purity of 99.7% and Ti with an average particle size of less than 70 μm and a purity of 96% 2 AlC powder is put into a ball mill with a molar ratio of 5:1 for ball milling. Set the ball milling ratio to 10:1, the rotational speed to 300r / min, and the ball milling time to be more than 8 hours. Add alcohol as a ball milling aid during the milling process, and the milling is complete. Then put the ball mill into the dryer to dry for 2 hours, and finally sieve the dried composite powder with a RetschAS200 mechanical vibrating sieve, and the particle size of the powder is 200 mesh;

[0027] 1. Prepare TC4 foil layer: cut all TC4 foils with a thickness of 0.15mm into foil layers of 100×1...

Embodiment 2

[0036] Example 2: Ti-Ti with a cylindrical staggered stacked structure 2 AlC / TiAl 3 A method for preparing a laminated composite material, comprising the steps of:

[0037] , Preparation of uniformly mixed composite powder: Aluminum powder with an average particle size of less than 30 μm and a purity of 99.9% and Ti with an average particle size of less than 70 μm and a purity of 98.5% 2 AlC powder is put into a ball mill with a molar ratio of 20:1 for ball milling. Set the ball milling ratio to 10:1, the speed to 300r / min, and the ball milling time to be more than 8 hours. Add alcohol as a ball milling aid during the milling process, and the milling is completed. Then put the ball mill into the drying machine to dry for 2 hours, and finally use the RetschAS200 mechanical vibrating sieve to sieve the dried composite powder. The particle size of the composite powder after sieving is 300 mesh;

[0038] 1. Prepare TC4 foil layer: cut all TC4 foils with a thickness of 0.15mm...

Embodiment 3

[0047] Embodiment 3: Ti-Ti of a kind of cylindrical staggered stacking structure 2 AlC / TiAl 3 A method for preparing a laminated composite material, comprising the steps of:

[0048] , Preparation of uniformly mixed composite powder: Aluminum powder with an average particle size of less than 30 μm and a purity of 99.9% and Ti with an average particle size of less than 70 μm and a purity of 98% 2 AlC powder is put into a ball mill with a molar ratio of 10:1 for ball milling. Set the ball milling ratio to 10:1, the speed to 300r / min, and the ball milling time to be more than 8 hours. Add alcohol as a ball milling aid during the milling process, and the milling is completed. Then put the ball mill into the drying machine to dry for 2 hours, and finally use the RetschAS200 mechanical vibrating sieve to sieve the dried composite powder. The particle size of the composite powder after sieving is 350 mesh;

[0049] 1. Prepare TC4 foil layer: cut all TC4 foils with a thickness o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com