Fe-Ni base alloy welding wire for 800h alloy welding and preparation method thereof, welding method of 800h alloy

A technology of 800H and welding method, applied in the direction of welding equipment, welding equipment, welding medium, etc., can solve the problems of decreased tensile strength and hidden dangers in the safe operation of nuclear power units

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

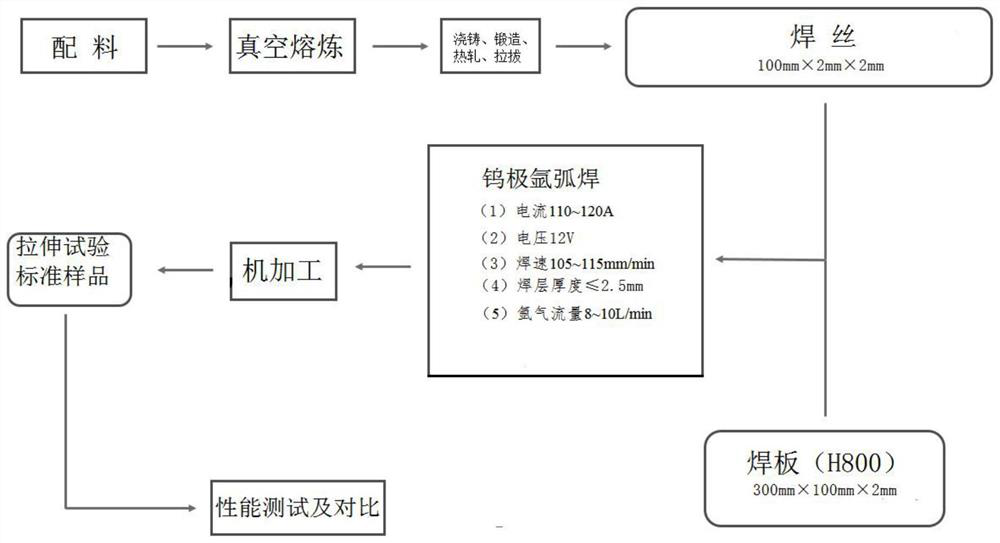

[0045] The present invention provides the preparation method of Fe-Ni base alloy welding wire for 800H alloy welding described in above-mentioned technical scheme, comprises the following steps:

[0046] According to the chemical composition batching of the Fe-Ni base alloy welding wire described in the above technical solution, the obtained raw material mixture is then subjected to vacuum melting, casting, forging, hot rolling and drawing in sequence to obtain the Fe-Ni base alloy welding wire.

[0047] The present invention has no special requirements on the sources of raw materials corresponding to the chemical components in the Fe-Ni-based alloy welding wire described in the above technical solution, and those well-known to those skilled in the art can be used. It should be noted that the S, P, and N elements are impurity elements in the raw materials corresponding to the Fe component, and no additional addition is required.

[0048] After batching, the present invention c...

Embodiment 1

[0065] according to figure 1 The flow chart shown in the test is carried out:

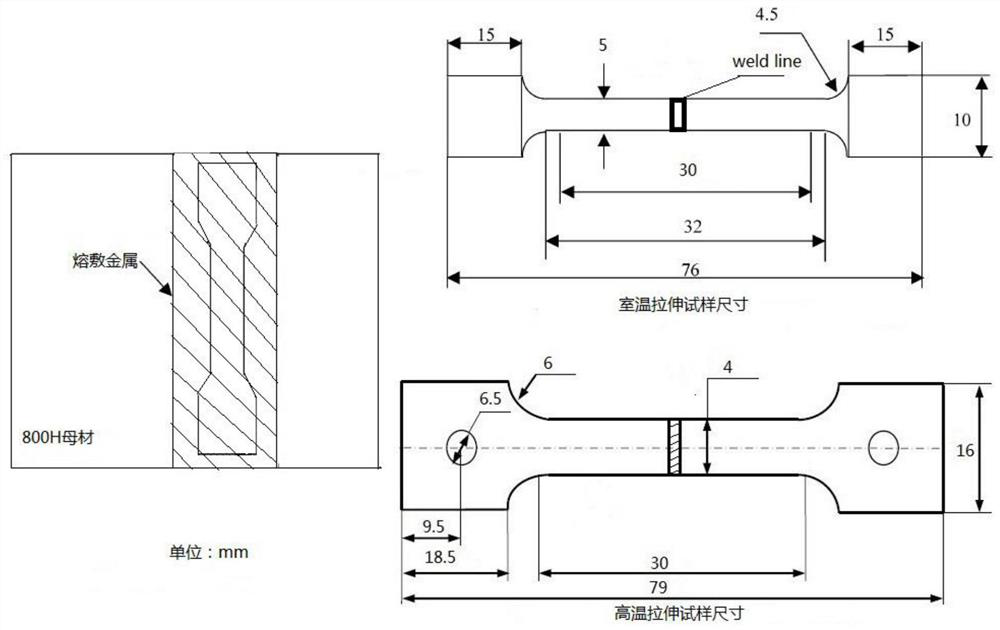

[0066] Dispensing according to the chemical composition shown in Table 1, followed by melting in a vacuum induction melting furnace (ZG-0.05), vacuum melting at 1590°C at 1 Pa, and casting, followed by forging, hot rolling and drawing in sequence, among which forging and the process parameters of hot rolling are listed in table 2, obtain the Fe-Ni base alloy welding wire that diameter is 1.2mm, for subsequent use;

[0067] Using the above-mentioned Fe-Ni-based alloy welding wire as the filler wire, argon tungsten arc welding was performed on the 800H alloy plate (300mm×100mm×2mm). The welding process parameters are shown in Table 3.

Embodiment 2~5

[0069] According to the method of Example 1, Fe-Ni-based alloy welding wire was provided, and argon tungsten arc welding was performed. The chemical composition, preparation conditions and welding process parameters of the welding wire are listed in Tables 1-3 respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com