Preparation method of latex condensate, edge pressing latex mold cup, preparation method and application

A cured product and latex technology, applied in applications, bras, clothing, etc., can solve the problems of inability to perform secondary shaping and processing, and achieve the effects of uniform force bearing, improved force bearing point, and good strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0073] A method for preparing a solidified latex includes the following steps:

[0074] S01: Mix the raw material latex and the dispersion, stir and foam to obtain a latex foam;

[0075] S02: spray latex foam on the carrier;

[0076] S03: Add a gelling agent to the latex foam sprayed on the carrier, and then keep it at a temperature of 65-75°C for 5-15 minutes to obtain a cured latex.

[0077] A solidified latex prepared by the above method.

[0078] In one embodiment, the above-mentioned cured latex is used in precision foamed latex products.

[0079] In one embodiment, the foamed latex precision products in the present invention include impregnated products, sponge products, woven products and the like.

[0080] The latex cured product can be used to obtain the foamed latex precision product through conventional molding and thermal vulcanization processes.

[0081] The molding may adopt a compression molding method. The pressure of the molding press used for the compression molding may ...

Embodiment 1

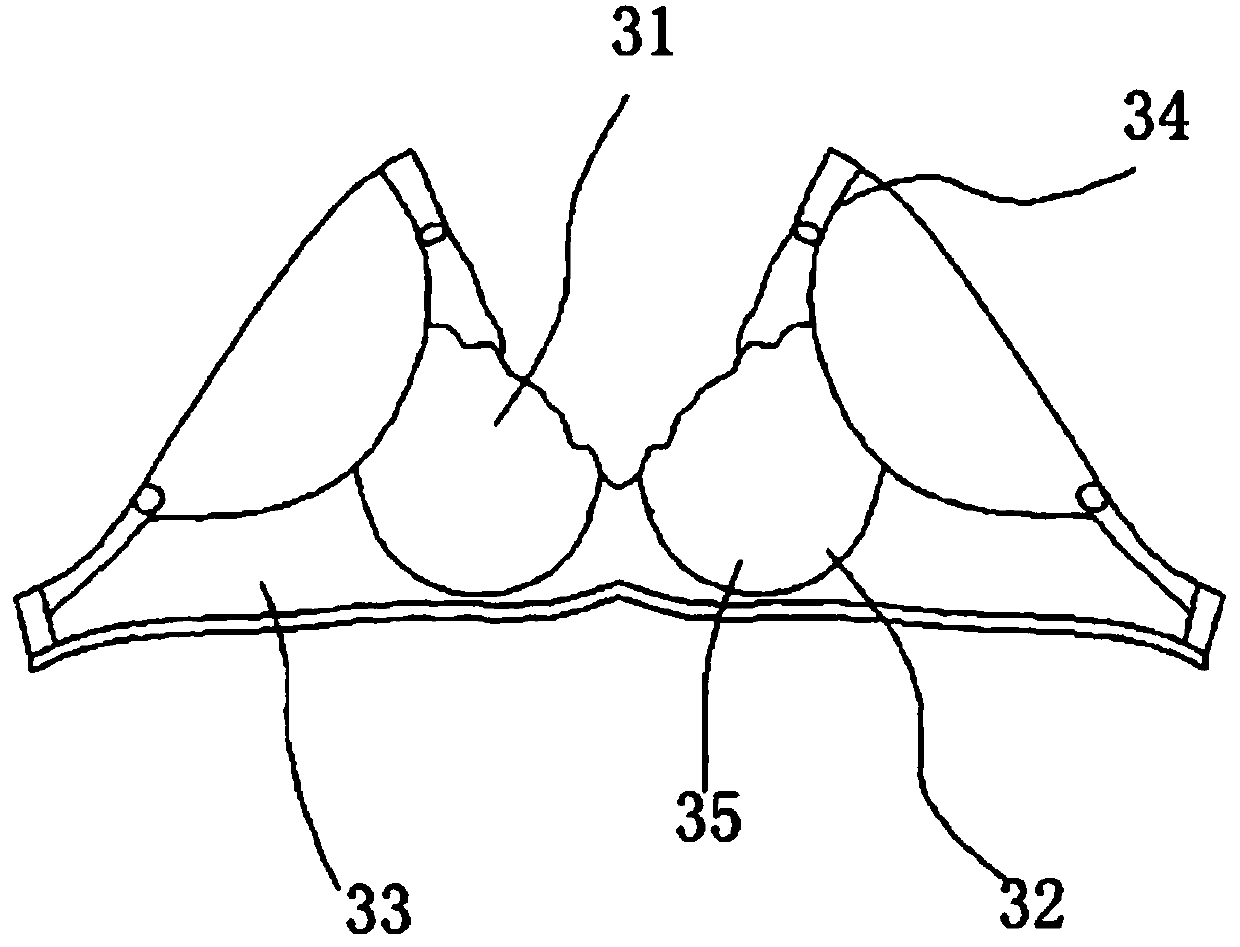

[0152] A method for preparing an edge-pressed latex mold cup includes the following steps:

[0153] S01: Mix the raw material latex and the dispersion, and foam at 900r / min for mechanical stirring for 10 minutes to obtain a latex foam;

[0154] S02: spray latex foam on the carrier;

[0155] S03: Add a gelling agent to the latex foam sprayed on the carrier, and then keep the temperature at 70°C for 10 minutes to prepare a latex cured product;

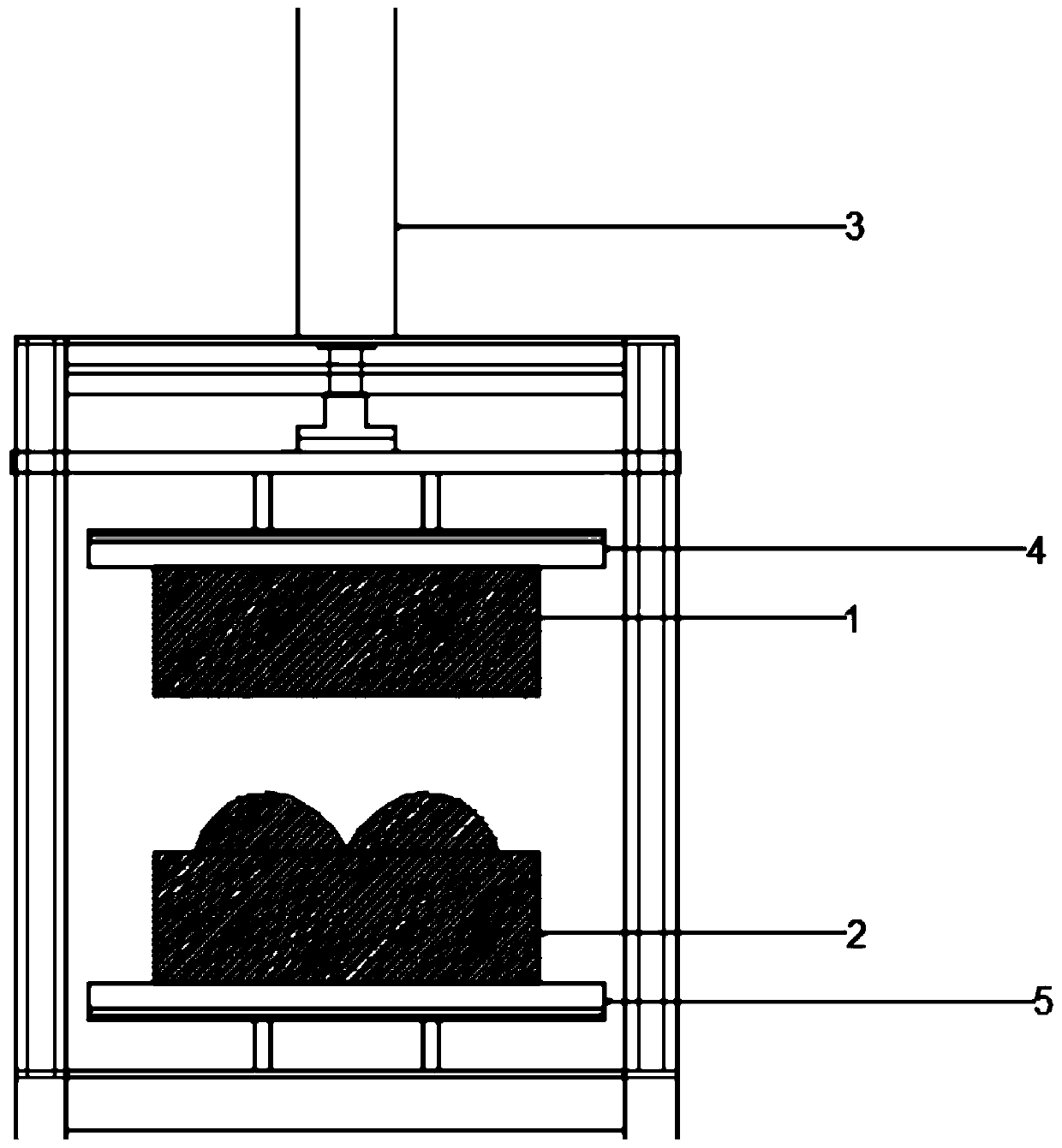

[0156] S04: Transfer the cured latex to the mold cup of the vulcanizer;

[0157] S05: The curing press is heated and pressurized to press, shape and vulcanize the cured latex;

[0158] S06: Hot water leaching and drying.

[0159] In the step S01, the raw material latex is natural rubber.

[0160] In the step S01, the mass ratio of the raw material latex and the dispersion is 9:1.

[0161] In the step S01, the dispersion includes 2 parts by weight of vulcanizing agent, 1 part by weight of accelerator, 2.5 parts by weight of anti-aging agent, 1.2 parts ...

Embodiment 2

[0179] A method for preparing an edge-pressed latex mold cup includes the following steps:

[0180] S01: Mix the raw material latex and the dispersion, and foam at 900r / min for mechanical stirring for 10 minutes to obtain a latex foam;

[0181] S02: spray latex foam on the carrier;

[0182] S03: Add a gelling agent to the latex foam sprayed on the carrier, and then keep the temperature at 70°C for 10 minutes to prepare a latex cured product;

[0183] S04: Transfer the cured latex to the mold cup of the vulcanizer;

[0184] S05: The curing press is heated and pressurized to press, shape and vulcanize the cured latex;

[0185] S06: Hot water leaching and drying.

[0186] In the step S01, the raw material latex is natural rubber.

[0187] In the step S01, the mass ratio of the raw material latex and the dispersion is 9:1.

[0188] In the step S01, the dispersion includes 2 parts by weight of vulcanizing agent, 1 part by weight of accelerator, 2.5 parts by weight of anti-aging agent, 1.2 parts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com