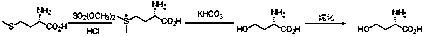

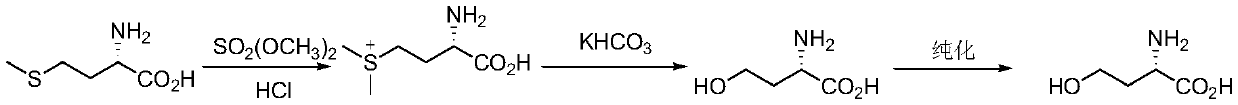

Preparation method of L-homoserine

A technology of homoserine and methionine, which is applied in the preparation of organic compounds, organic chemical methods, cyanide reaction preparation, etc., can solve the problems of high price of methyl iodide, unfavorable production amplification, complicated operation, etc., and reduce the use of toxic solvents. , Easy to operate, less dosage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] S1: In a 3-liter three-necked flask, add 1,500 grams of water, then 298 grams of L-methionine, stir well, then add 260 grams of concentrated hydrochloric acid, stir until clear, then add 441 grams of dimethyl sulfate dropwise at 25°C , stirred at room temperature for two days, spotted the plate to monitor the disappearance of the raw materials, and obtained the L-methionine sulfonium salt reaction liquid;

[0024] S2: The L-methionine sulfonium salt reaction solution obtained in S1 is heated to a reflux state for reaction, then slowly drips a saturated potassium bicarbonate solution (100 grams of potassium bicarbonate is dissolved in 500 grams of water), and the dropwise process controls the pH at 3- -6, continue to reflux reaction for 6 hours after dripping, and the raw materials basically disappear by pointing board monitoring;

[0025] S3: Lower the reaction solution to room temperature, then condense the film to remove most of the water, pre-cool the concentrate to ...

Embodiment 2

[0027] S1: In a 5-liter three-neck flask, add 2250 grams of water, then add 447 grams of L-methionine, stir well, then add 390 grams of concentrated hydrochloric acid, stir until clear, then add 661 grams of dimethyl sulfate dropwise at 25°C , stirred at room temperature for two days, spotted the plate to monitor the disappearance of the raw materials, and obtained the L-methionine sulfonium salt reaction solution.

[0028] S2: The above-mentioned L-methionine sulfonium salt reaction liquid is heated up to reflux state for reaction, and then slowly add saturated potassium bicarbonate solution (150 grams of potassium bicarbonate dissolved in 750 grams of water), and the pH is controlled at 3-- 6. Continue the reflux reaction for 6 hours after the dripping is completed, and the raw materials basically disappear by pointing the board monitoring.

[0029] S3: Lower the reaction solution to room temperature, then condense the film to remove most of the water, pre-cool the concentra...

Embodiment 3

[0031] S1: In a 2-liter three-neck flask, add 1000 grams of water, then 179 grams of L-methionine, stir well, then add 156 grams of concentrated hydrochloric acid, stir until clear, then add 265 grams of dimethyl sulfate dropwise at 25 °C , stirred at room temperature for two days, spotted the plate to monitor the disappearance of the raw materials, and obtained the L-methionine sulfonium salt reaction solution.

[0032] S2: The above-mentioned L-methionine sulfonium salt reaction solution is heated to reflux state for reaction, then slowly add saturated potassium bicarbonate solution (60 grams of potassium bicarbonate dissolved in 300 grams of water), and the pH is controlled at 3-- 6. Continue the reflux reaction for 6 hours after the dripping is completed, and the raw materials basically disappear by pointing the board monitoring.

[0033] S3: Lower the reaction solution to room temperature, then condense the film to remove most of the water, pre-cool the concentrated solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com