Alcohol extraction method of sea cucumber intestinal egg oil, and sea cucumber intestinal egg oil obtained therethrough

A sea cucumber sausage and alcohol extraction technology, which is applied in the fields of pharmaceutical formula, edible oil/fat, fat oil/fat production, etc., can solve the problems of uneconomical processing of sea cucumber by-products, production environment, high personnel requirements, and high cost of sea cucumber sausage egg oil , to avoid oxidative deterioration of raw materials, easy to recycle, maintain the freshness of raw materials and retain nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

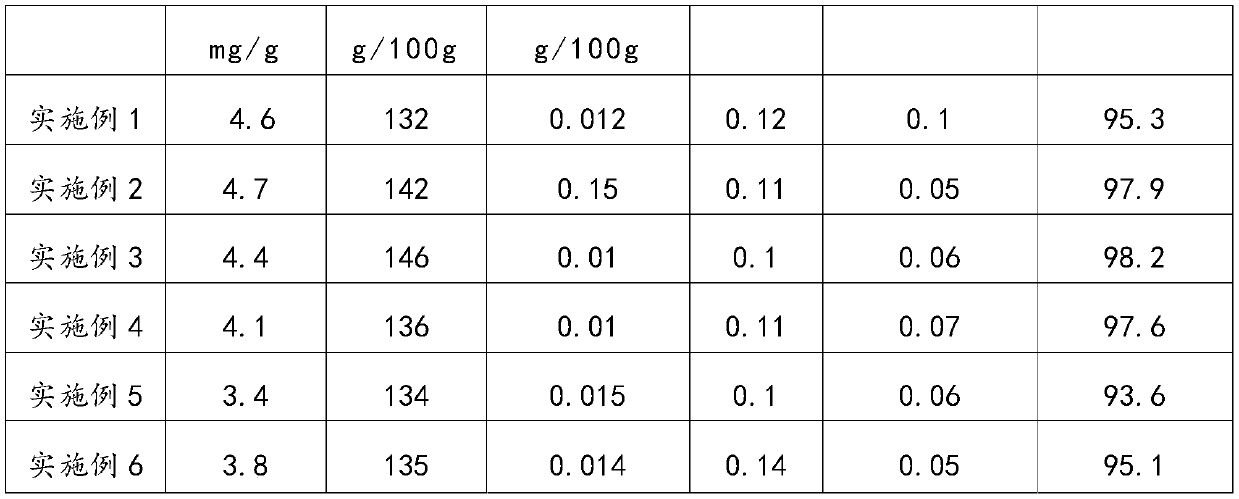

Embodiment 1

[0026] Select sea cucumber intestinal egg raw materials with good integrity in the same batch, and require fresh raw materials, no impurities, no peculiar smell, etc. Freeze-drying at -40°C after packing into trays to obtain the raw material of freeze-dried sea cucumber intestinal eggs;

[0027] Crush the raw material of freeze-dried sea cucumber intestinal eggs with a pulverizer, and the particle size must be ≥60 mesh. After crushing, check the cleanliness, and remove any foreign matter such as shellfish and seaweed in time;

[0028] Use anhydrous ethanol at 40°C and 60RPM to conduct a heating and stirring extraction for 240min, then conduct a second heating and stirring extraction at 40°C and 60RPM for 240min, combine the two extracts and centrifuge at 4000RPM Treat for 20min to obtain the centrifugate;

[0029] Ethanol is removed from the centrifuge at 60-65°C and 0.01MPA low-temperature vacuum until the centrifuge has no ethanol smell, and sea cucumber intestinal egg crud...

Embodiment 2

[0033] The steps are the same as those in Example 1, the difference is that the condition of heating and stirring extraction once is to process 180min at 50°C and 200RPM rotation speed, and the condition of heating and stirring extraction for the second time is to process 180min at 50°C and 200RPM rotation speed, and the separation conditions are Centrifuge at 5000RPM for 15min.

Embodiment 3

[0035] The steps are the same as in Example 1, the difference is that the condition of heating and stirring extraction once is to process 140min at 60°C and 450RPM rotation speed, and the condition of heating and stirring extraction for the second time is to process 140min at 60°C and 450RPM rotation speed, and the separation conditions are Centrifuge at 6500RPM for 11min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com