Generator set yaw drive system and method and generator set yaw system

A yaw drive and generator set technology, applied in the direction of engine, wind power generation, engine components, etc., can solve the problems of affecting power generation, increasing system complexity, and high replacement costs, shortening replacement time, flexible installation methods, and improving maintenance. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Aiming at the defects of the existing generating set yaw system, the invention proposes a non-contact magnetoelectric yaw driving mode to replace the existing contact gear meshing yaw driving mode. The non-contact magnetoelectric yaw driving method and yaw driving system are used for the yaw system of a wind turbine as an example, and the specific embodiments are described as follows:

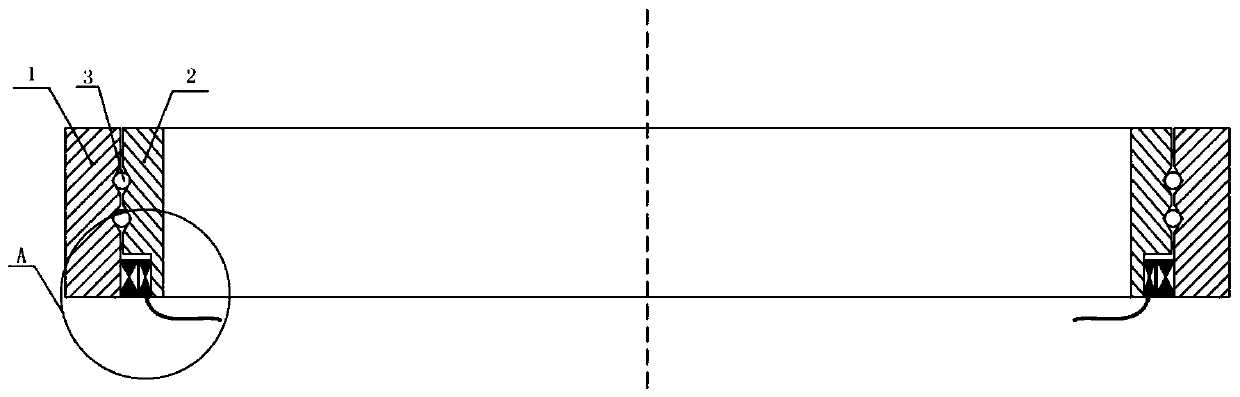

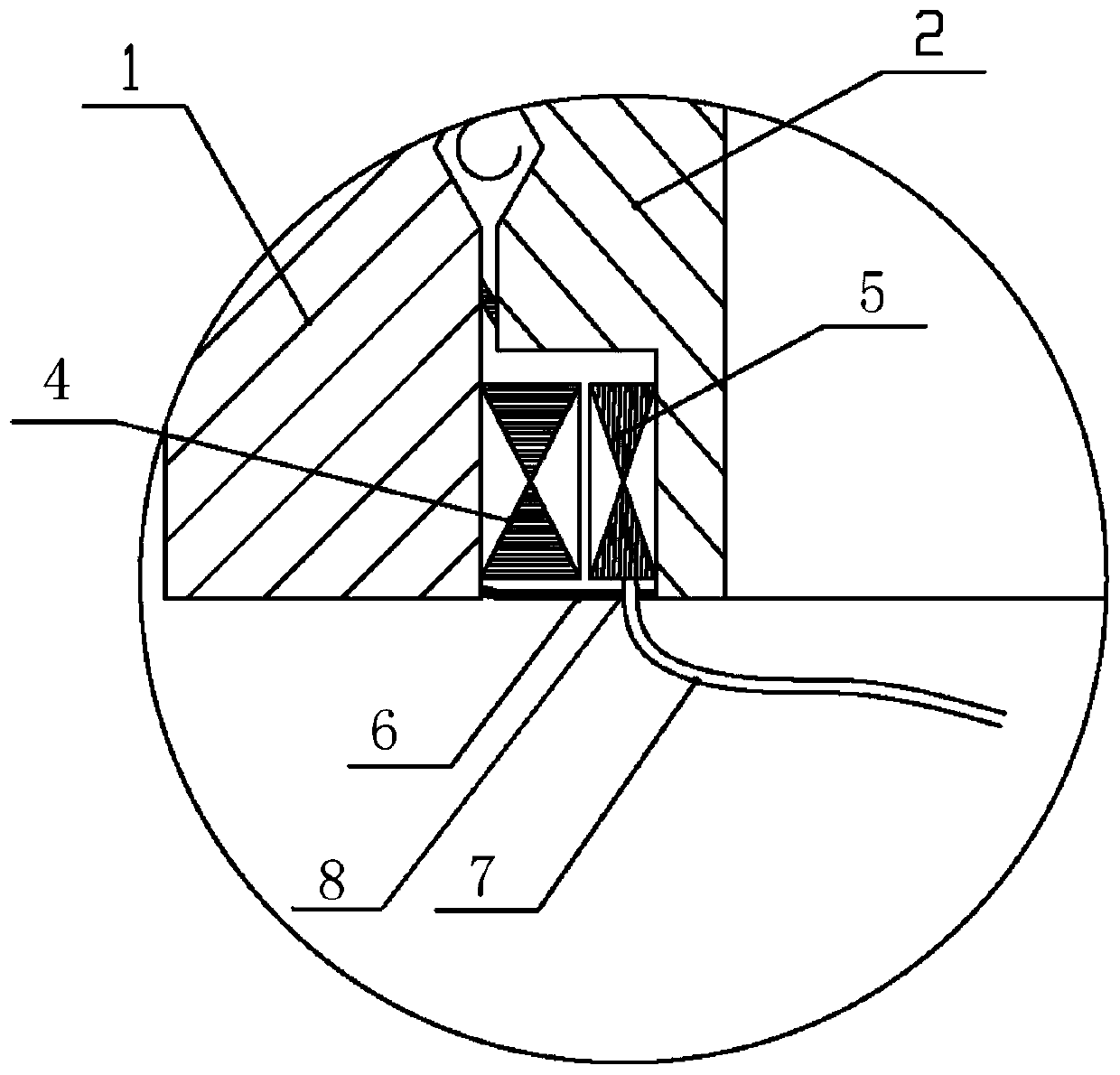

[0029] Refer to attached figure 1 and 2 As shown, the magnetoelectric yaw drive system of this embodiment includes a stator 4 and a rotor 5 which are respectively relatively fixed on the fixed part 1 of the slewing bearing and the rotating part 2 of the slewing bearing of the wind turbine, and a servo drive that provides excitation current for the rotor 5 mechanism. The rotor 5 rotates relative to the stator 4 under the action of the servo drive mechanism, and then drives the slewing support rotating part 2 connected to it to realize yaw motion relative to the slewing support fixed par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com