Novel graphite nanocarbon radiating fin

A nano-carbon and heat sink technology, applied in electrical components, electrical solid devices, circuits, etc., can solve the problems of weak withstand voltage, low emissivity, poor performance of graphite heat sinks, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

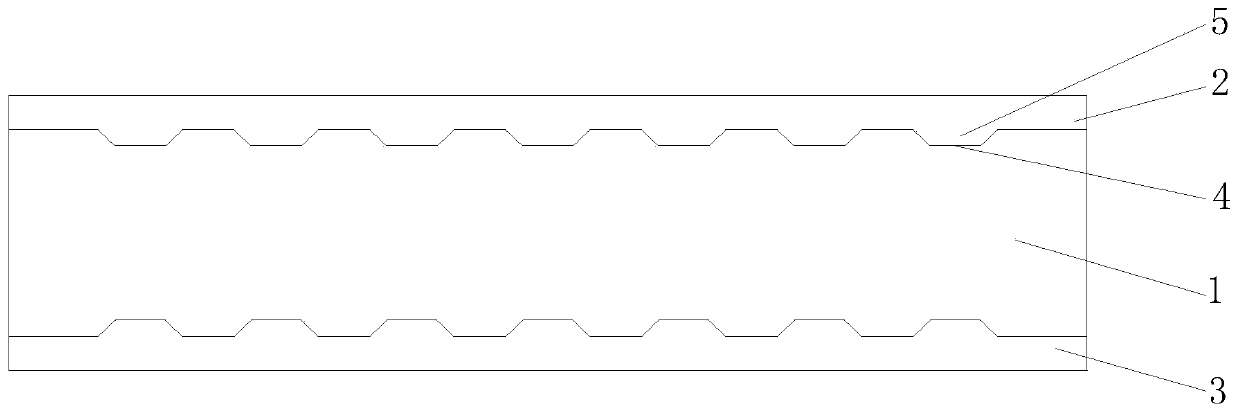

[0031] A new graphite nano-carbon heat sink, comprising a graphite substrate 1, the upper surface of the graphite substrate 1 is coated with an upper nano-carbon layer 2, the lower surface of the graphite substrate 1 is coated with a lower nano-carbon layer 3, and the graphite substrate 1 Grooves 4 are provided on the upper and lower surfaces of the upper and lower nanocarbon layers 2 and 3, and protrusions 5 matching the grooves 4 are arranged on the upper and lower nanocarbon layers 3. Groove 4 is provided with several, and several grooves 4 are equidistantly arranged in parallel on the upper and lower surfaces of graphite substrate 1, and the thickness of graphite substrate 1 is set to 1-2 millimeters, and the thickness of upper nanocarbon layer 2 and lower nanocarbon layer 3 The thicknesses are all set to 20 microns, and the depth of the groove 4 is set to 20 microns.

[0032] The preparation steps of the novel heat sink are as follows:

[0033] Step 1: Process a pluralit...

Embodiment 2

[0040] A novel graphite nanocarbon heat sink, comprising a graphite substrate 1, an upper nanocarbon layer 2 coated on the upper surface of the graphite substrate 1, a lower nanocarbon layer 3 coated on the lower surface of the graphite substrate 1, and a graphite substrate 1 The thickness is set to 1-2 millimeters, and the thickness of the upper nanocarbon layer 2 and the lower nanocarbon layer 3 are both set to 20 microns.

[0041] The preparation steps of the novel heat sink are as follows:

[0042] Step 1: Put the graphite base material 1 into the cleaning tank for ultrasonic cleaning for 5 minutes, pick it up after the ultrasonic cleaning, rinse it with distilled water for 1 minute, and then put the graphite base material 1 into the drying box for drying;

[0043] Step 2: adding carbon nanotubes to deionized water or pure ethanol, and then ultrasonically treating for 60 minutes to obtain nanocarbon suspension;

[0044] Step 3: adding the nano-carbon suspension into the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com